Multiplier stage for photomultiplier tube and preparation method thereof

A photomultiplier and useful technology, applied in electron multiplier dynodes, electron multiplier details, dynodes and other directions, can solve the problem that the finished product is difficult to meet the shape requirements of the dynode material, the hard and brittle second phase is easy to become a crack source, and the secondary The problem of reducing the secondary emission coefficient, etc., can improve the gain effect and anti-aging performance, improve the aging hardening effect, and improve the adsorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

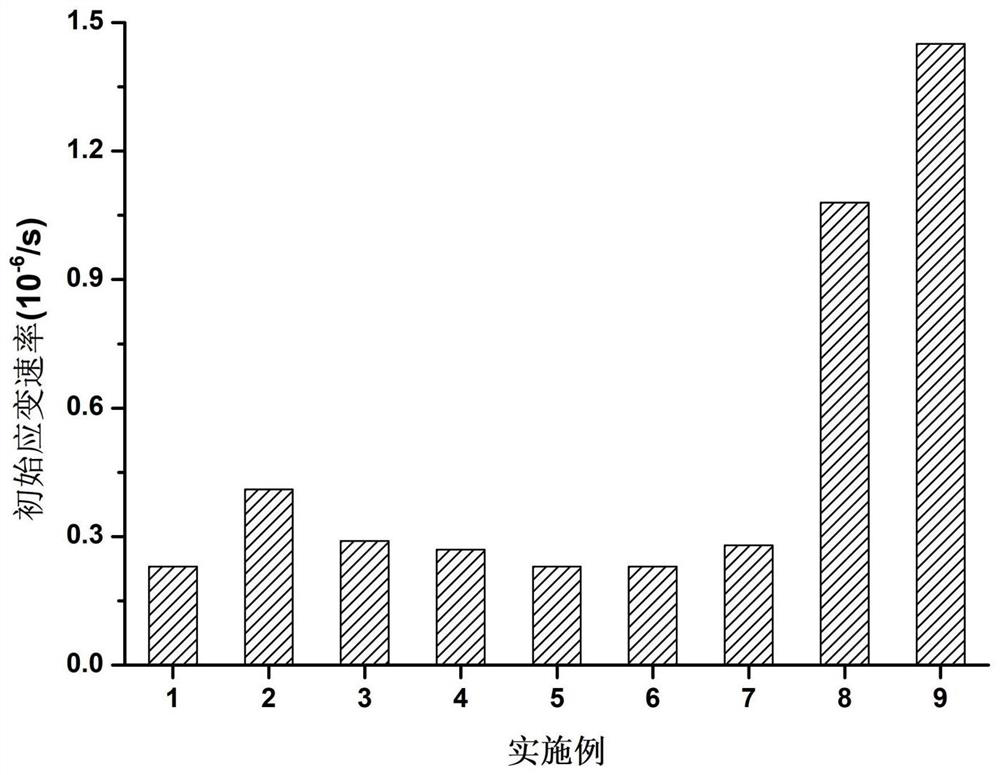

Embodiment 1

[0062] Embodiment 1: a kind of copper beryllium alloy:

[0063] This embodiment provides a copper-beryllium alloy, each component is calculated by weight percentage, including: Be: 2.5%, Co: 0.4%, Ni: 0.45%, Zr: 0.6%, Ce: 0.045%, and the balance is Cu And unavoidable impurity; Namely the weight ratio of Ce, Be is Ce / Be=0.018;

[0064] The copper beryllium alloy is prepared by the following method:

[0065] Under the protection of argon, high-purity Cu is smelted at 1300°C, and then Be, Co, Ni, Zr, and Ce are added for smelting. After complete melting, refining agent (addition amount is 25g / kg) is added for refining, and the slag is removed. , and then held at 1150°C for 13 minutes; semi-continuous casting process was used for casting and slag removal, the casting temperature was 1050°C, the casting speed was 70mm / min, and the cooling water flow rate was 11m 3 / h; solution treatment at 840°C for 3h, rapid cooling to 770°C for solution treatment for 6h; hot extrusion treatment...

Embodiment 2

[0071] Embodiment 2: another kind of copper beryllium alloy:

[0072] This embodiment provides another copper-beryllium alloy, each component is calculated by weight percentage, including: Be: 2.5%, Co: 0.4%, Ni: 0.45%, Zr: 0.6%, the balance is Cu and unavoidable Impurities; that is, without adding Ce;

[0073] The preparation method of copper-beryllium alloy is the same as that of Example 1.

Embodiment 3

[0074] Embodiment 3: another kind of copper beryllium alloy:

[0075] This embodiment provides another copper-beryllium alloy, each component is calculated by weight percentage, including: Be: 2.5%, Co: 0.4%, Ni: 0.45%, Zr: 0.6%, Ce: 0.025%, and the balance is Cu and unavoidable impurities; that is, the weight ratio of Ce and Be is Ce / Be=0.01;

[0076] The preparation method of copper-beryllium alloy is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com