Tubular PTFE covered stent and preparation method thereof

A stent-graft, PTFE technology, applied in stents, coatings, filament/wire forming, etc., can solve the problem of little research on vascular stent covering, and achieve good water permeability, good mechanical properties, and blood compatibility. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

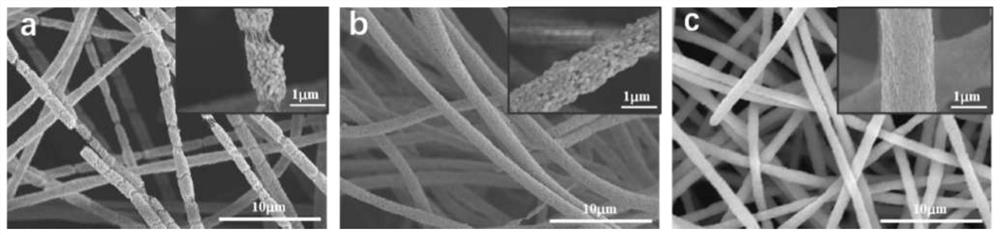

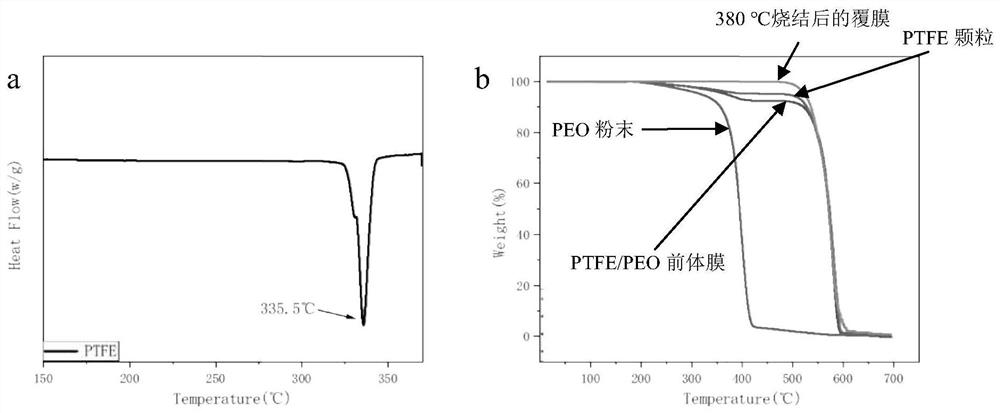

[0037] 1. Preparation of PTFE / PEO precursor membrane

[0038] Weigh an appropriate amount of PEO powder with an Adventurer electronic balance (Changzhou Ohaus Instrument Co., Ltd.) and add it to deionized water and stir it with a 84-1 magnetic stirrer (Shanghai Meiyingpu Instrument Manufacturing Co., Ltd.) until it is completely dissolved to obtain 4wt% PEO water solution. Weigh the PTFE dispersion emulsion, mix the PEO aqueous solution and the deionized water, stir continuously until uniform, and obtain the electrospinning solutions with different ratios of PTFE / PEO. The spinning solution was introduced into a 5mL syringe, and the mandrel (4 mm in diameter) wrapped with a stainless steel braided sleeve was used as a receiving device for electrospinning (JDS02 electrospinning machine, Changsha Nano Instrument Technology Co., Ltd.), and the setting Electrospinning parameters are: voltage 15kV, injection speed 8μL / min, receiving distance 20cm, receiver speed 400r / min, relative ...

Embodiment 2

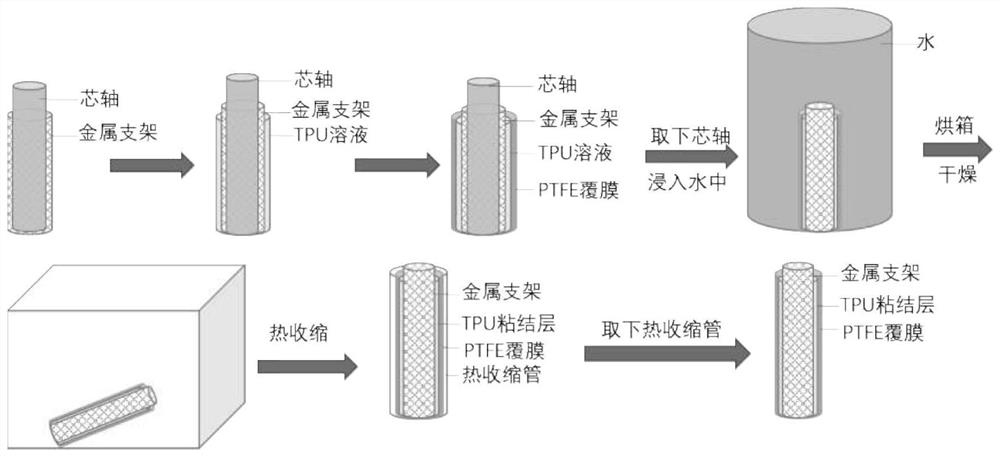

[0045] The difference between Example 2 and Example 1 is that the TPU electrospinning method is used to prepare the stent graft, and the specific operations are as follows:

[0046] Weigh an appropriate amount of TPU powder and dissolve it in DMF and stir until it is completely dissolved to obtain a 30wt% TPU electrospinning solution. Set the electrospinning parameters: the voltage is 16-17kV, and the mandrel wrapped with a metal bracket is used as the receiving device. The receiving distance is 15cm, the flow rate is 13.33μL / min, after a certain period of electrospinning, a tubular TPU electrospun membrane is obtained; then the above-mentioned sintered tubular PTFE film is placed outside the TPU electrospun membrane, and then a heat-shrinkable tube is added to the outermost layer , adjust the temperature of the heat gun to increase the temperature of the heat-shrinkable tube to melt the TPU electrospun membrane, thereby bonding the PTFE membrane to the metal stent, and the shr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com