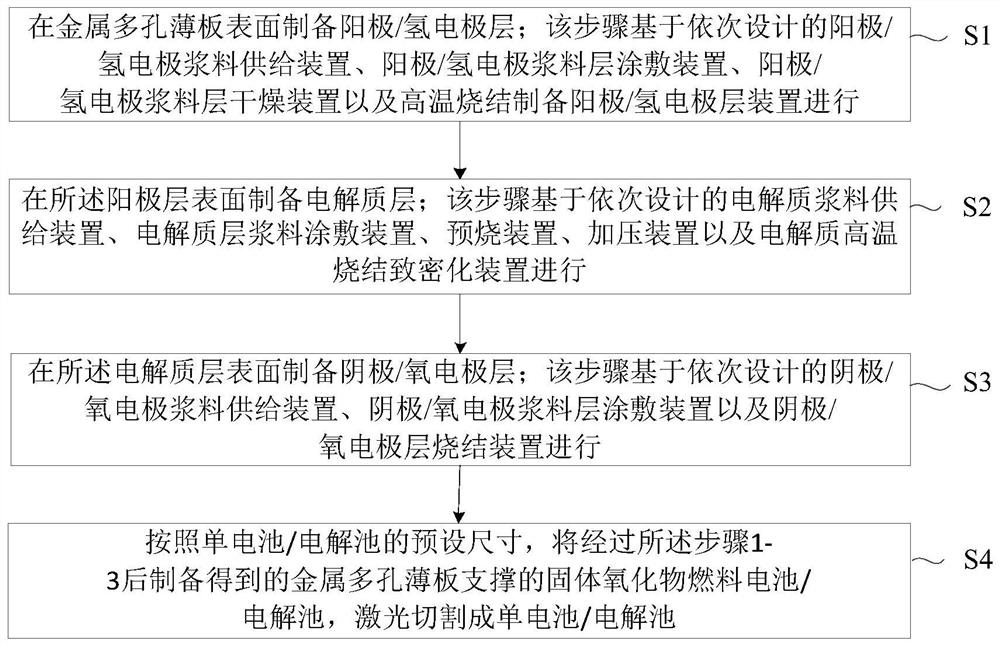

Method and system for continuously producing cell/electrolytic cell and battery/electrolytic cell

An electrolytic cell and battery technology, which is applied in the direction of battery electrodes, fuel cell parts, fuel cells, etc., can solve the problems of low battery yield, high manual error, and complicated operating procedures, so as to achieve continuous production and reduce poor performance. Effect of stabilizing phenomena and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

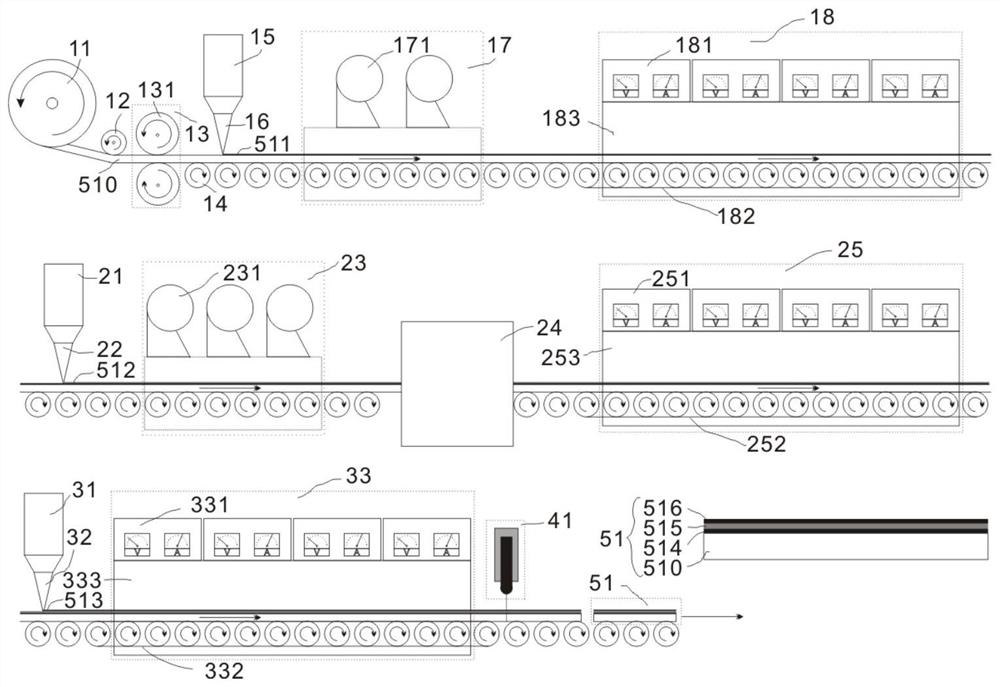

[0101] Firstly, a ferritic stainless steel plate with a chromium content of 18wt%, a porosity of 15%, and a thickness of 50 μm is selected as the material of the metal porous sheet support body, and the bent ferritic stainless steel plate is rolled by a sheet coil flattening device. Made into a flat ferritic stainless steel plate, that is, a metal porous sheet support. After passing through the conveying rollers, the metal porous thin plate support body is sent to the anode preparation area.

[0102] In the anode preparation area, a layer of NiO-GDC anode slurry layer containing a quantitative pore-forming agent is coated on the surface of the metal porous sheet support by the anode slurry layer coating device, and then passed through the anode slurry layer drying device at 90 °C for drying. After drying, it is sintered at 1000° C. in an anode layer high-temperature sintering device to form a porous anode layer with a thickness of 30 μm. Then, the metal porous thin plate sup...

Embodiment 2

[0106]First, a ferritic stainless steel plate with a chromium content of 25wt%, a porosity of 45%, and a thickness of 200 μm is selected as the material of the metal porous sheet support body, and the bent ferritic stainless steel plate is rolled by a sheet coil flattening device. Made into a flat ferritic stainless steel plate, that is, a metal porous sheet support. After passing through the conveying rollers, the metal porous thin plate support body is sent to the anode preparation area.

[0107] In the anode preparation area, a layer of NiO-GDC anode slurry layer containing a quantitative pore-forming agent is coated on the surface of the metal porous sheet support by an anode slurry layer coating device, and then passed through an anode slurry layer drying device at 80 °C for drying. After drying, it is sintered at 1050°C in a high-temperature sintering device for the anode layer to form a porous anode layer, and the thickness of the anode is 30 μm. Then, the metal porou...

Embodiment 3

[0111] Firstly, a ferritic stainless steel plate with a chromium content of 35wt%, a porosity of 60%, and a thickness of 350 μm is selected as the material of the metal porous sheet support body, and the bent ferritic stainless steel plate is rolled by a sheet coil flattening device. Made into a flat ferritic stainless steel plate, that is, a metal porous sheet support. After passing through the conveying rollers, the metal porous thin plate support body is sent to the anode preparation area.

[0112] In the anode preparation area, a layer of NiO-ScSZ anode slurry layer containing a quantitative pore-forming agent is coated on the surface of the metal porous sheet support by an anode slurry layer coating device, and then passed through an anode slurry layer drying device at 100 °C for drying. After drying, it is sintered at 1200°C in a high-temperature sintering device for the anode layer to form a porous anode layer with a thickness of 50 μm. Then, the metal porous thin pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com