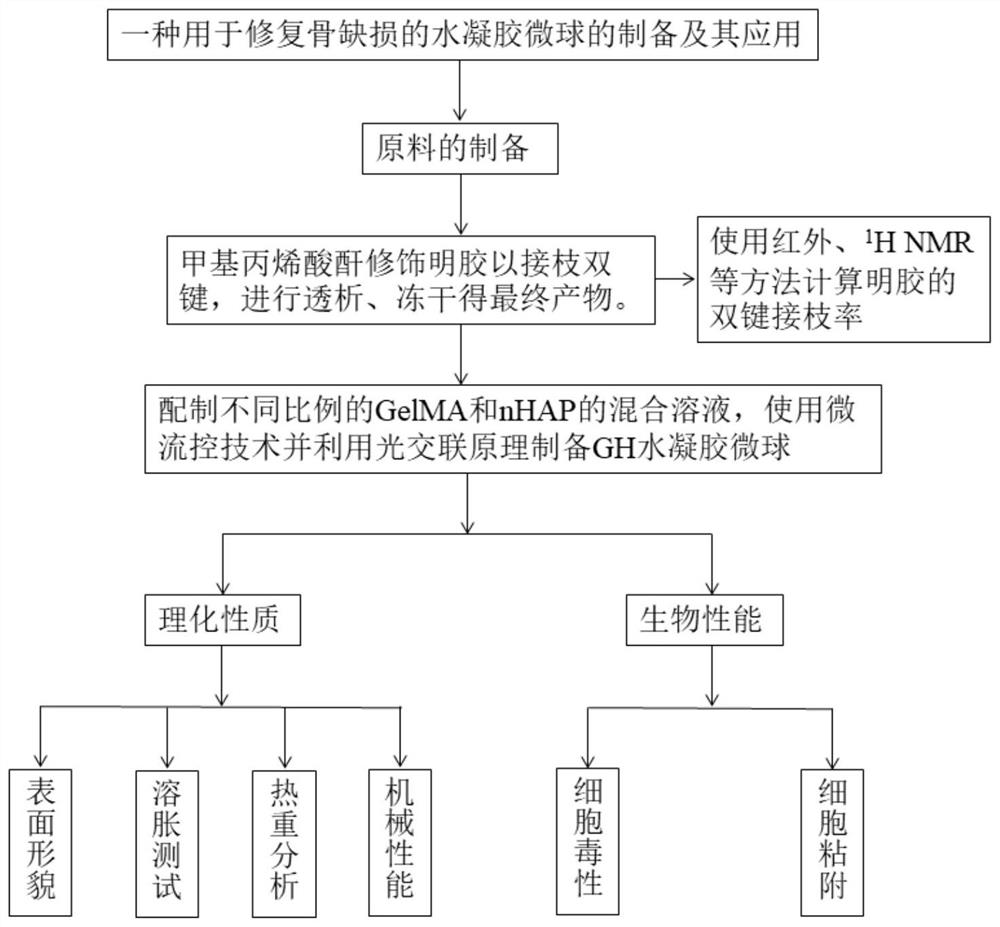

Hydrogel microspheres for repairing bone defects and preparation method thereof

A technology for hydrogel microspheres and bone defects, applied in the field of biomedicine, can solve the problems of poor biocompatibility and degradability, rough and porous surface, complicated preparation process, etc. Simple, cell proliferation-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The preparation of embodiment 1 GelMA

[0052] Accurately weigh 10g type A pigskin gelatin, and measure 100mL PBS into a round bottom flask, heat and stir in a water bath at 50°C for 30min to dissolve, after the gelatin is dissolved, slowly add 10mL under the condition of dark and vigorous stirring MA. After the MA dropwise addition was complete, the reaction was allowed to proceed for 24 h with full stirring and protected from light. Afterwards, the product was transferred to a dialysis bag (3500 Da), dialyzed at 40°C, and the distilled water was changed every 4 hours for a total of 6 dialyses. Finally, the product was lyophilized to obtain a loose and porous white solid product, namely GelMA, which was stored at -20°C.

Embodiment 2

[0054] GelMA product characterization:

[0055] Take a small amount of freeze-dried product GelMA and ground gelatin respectively, and use a Fourier transform infrared spectrometer to scan its infrared spectrum in the range of 400-4000 wavelength. In addition, the use of gelatin before and after methacrylation 1 Characterized by H NMR, 20mg GelMA and gelatin were dissolved in 0.5mL D 2 O, and then loaded into a nuclear magnetic resonance tube and tested with a nuclear magnetic resonance spectrometer. gelatin 1 H NMR spectra are extremely complex because gelatin consists of >20 different amino acids. The structure of these amino acid building blocks is -NH-CHR-CO-, in which the side chain (R) changes and has different functional groups, and it is very difficult to complete the complete analysis of the spectrum. For the calculation of DS, a peak corresponding to a group that cannot be modified must be selected, by recording the peaks of different amino acids 1 H NMR spectro...

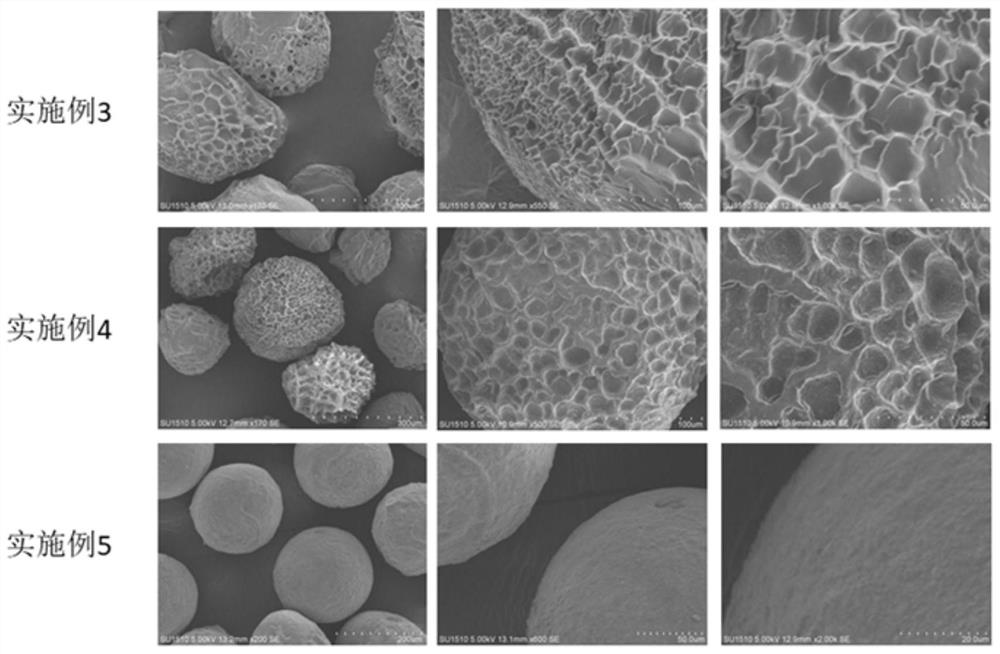

Embodiment 3

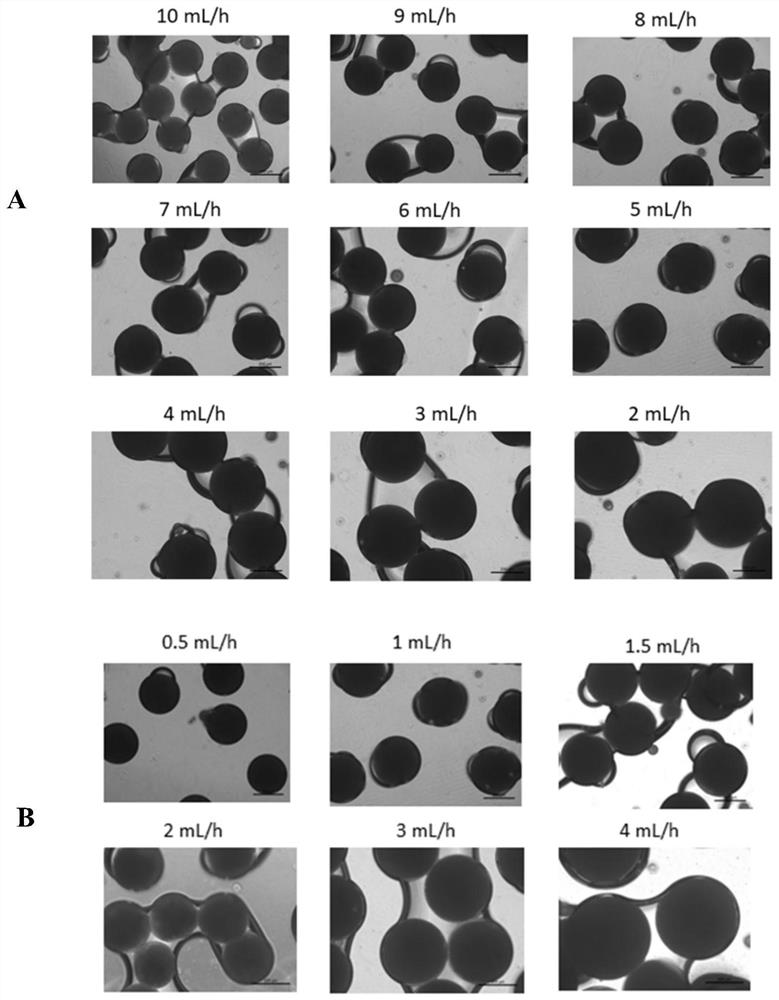

[0058] The preparation of embodiment 3 hydrogel microspheres

[0059] (1) Utilize the GelMA gained in Example 1 to disperse in water, prepare the GelMA solution of 10wt%, and add the mixed solution obtained after adding 0.25wt% LAP (photoinitiator) relative to the water quality, as the dispersed phase; Sesame oil as the continuous phase;

[0060] (2) The dispersed phase and the continuous phase in step (1) are injected into the microchannel respectively, and the dispersed phase forms monodisperse droplets due to the shear force under the promotion of two syringe pumps; wherein, the dispersed phase controls 4mL / h flow rate injection, continuous phase control 5mL / h flow rate injection. By adjusting the flow rates of the aqueous and oil phases, droplets with different size distributions can be obtained. Collected W / O emulsion at 25mW cm -2 Polymerized into microspheres after exposure to UV light (405 nm) for 60 s. Determine the size of the resulting microspheres using micros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com