Low-temperature activation efficient ammonia decomposition catalyst

An ammonia decomposition and catalyst technology is applied in the field of ammonia decomposition catalysis to achieve the effects of reducing stacking degree, improving catalytic performance and stability, and shortening crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

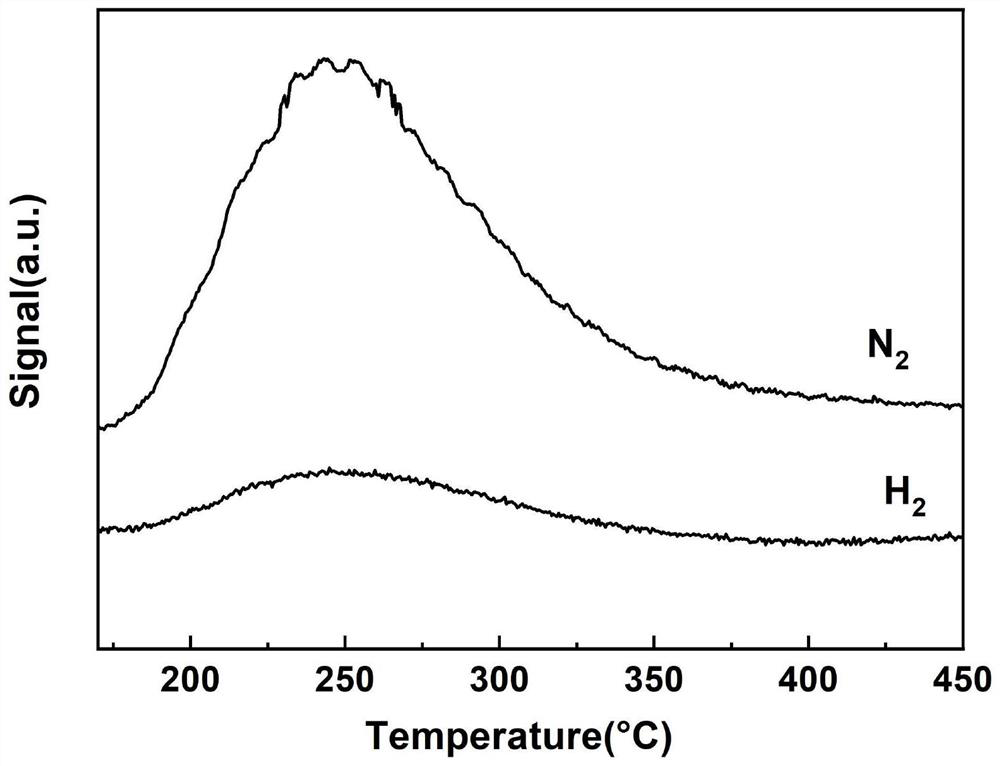

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The invention provides a method for preparing an ammonia decomposition catalyst activated at low temperature, which specifically comprises the following steps:

[0042] (1) Add nickel-containing carbon materials, silicon sources, aluminum sources, organic templates, inorganic bases, and solvents into the reactor in proportion, and continuously stir to obtain a gel, which is aged for later use;

[0043] (2) Transfer the gel obtained in step (1) to a hydrothermal reactor for crystallization to obtain a crystallized product;

[0044] (3) filtering and washing the crystallized product obtained in step (2), drying and roasting to obtain Ni-FER molecular sieve;

[0045] (4) placing the Ni-FER molecular sieve obtained in step (3) in an ammonium salt solution for ammonium ion exchange, drying after the exchange, and then roasting to obtain the Ni-HFER molecular sieve.

[0046] The preparation process of the above-mentioned nickel-containing carbon material is as follows:

[0...

Embodiment 1

[0050] (1) Pretreatment of carbon materials: put 5g of carbon nanotubes in 50mL of 1mol / L nitric acid, reflux at 65°C for 6h, dry at 110°C, and grind to above 120 mesh;

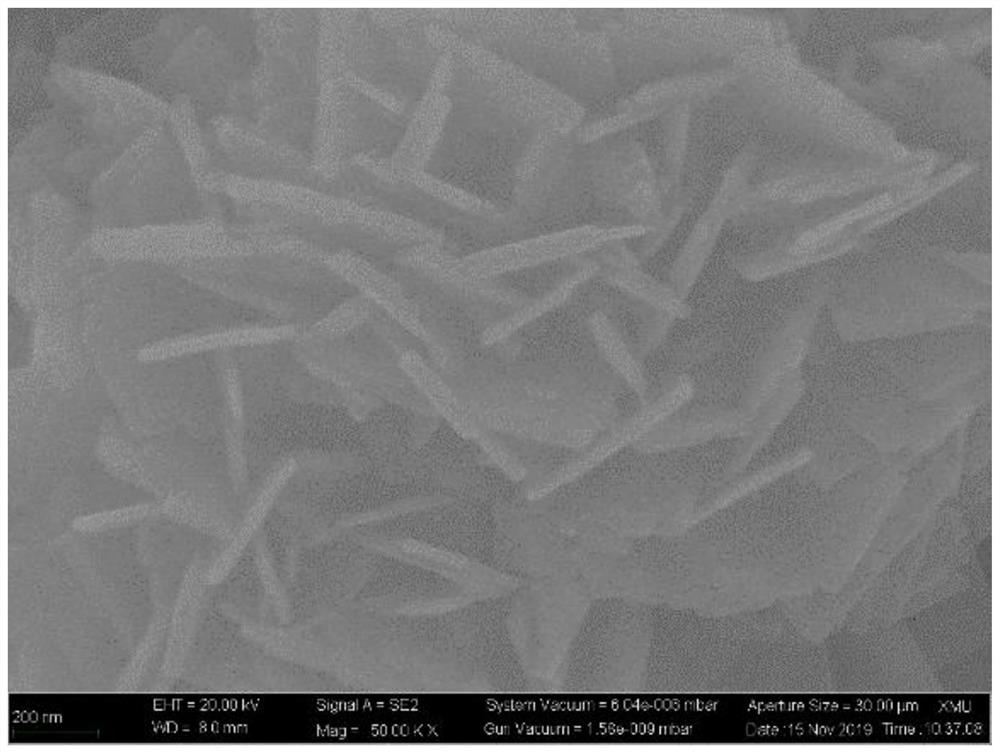

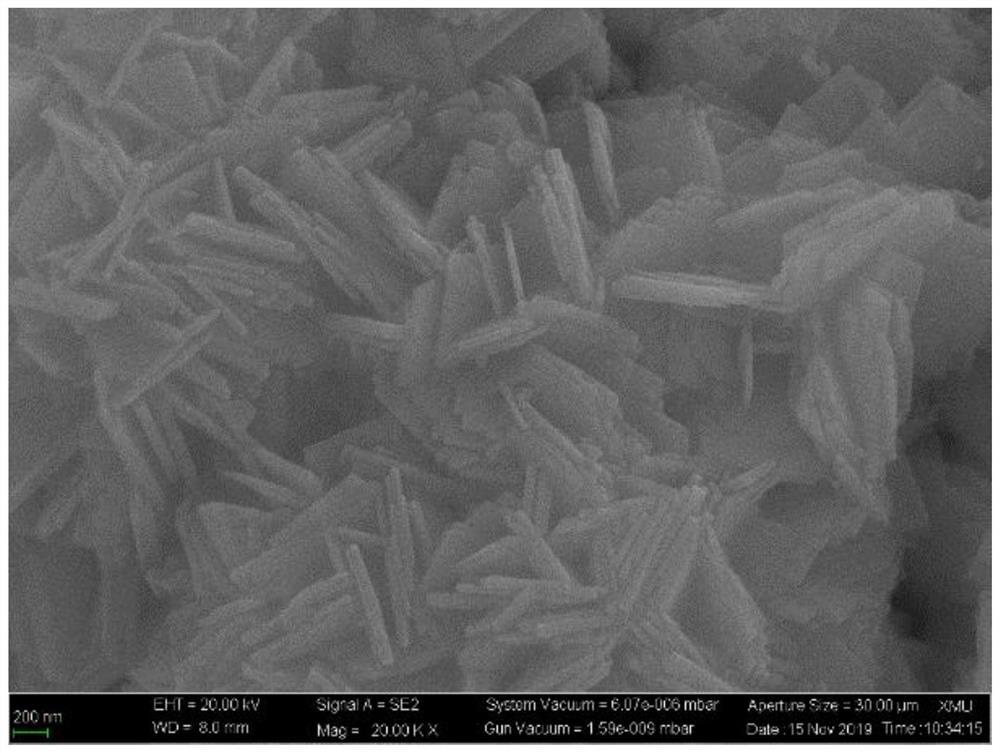

[0051] (2) Synthesis of nickel-containing carbon materials: 1 g of pretreated carbon nanotubes was placed in 10 mL, 0.2 mol / L Ni(NO 3 ) 2 solution, fully soaked and dried at 65°C for 24 hours, then roasted in a nitrogen atmosphere, using a temperature-programmed roasting process, the specific roasting conditions are: heating rate 5°C / min, roasting temperature 550°C, holding time 6h, to obtain Ni-CNT with 10% Ni loading;

[0052] (3) Synthesis of molecular sieve precursors: at room temperature, add 0.2g sodium hydroxide, 0.8g sodium metaaluminate, and 30ml deionized water into a 50mL beaker and stir until the solution is clear; then add 0.1g Ni-CNT, and sonicate for 2h Finally, first dropwise add 15g of alkaline silica sol (30wt.%), continue to stir for 1h until it becomes a uniform sol, then dropwise add 5m...

Embodiment 2

[0058] The difference between this embodiment 2 and embodiment 1 is that the CNT is replaced by graphene of equal mass, and other preparation processes are the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com