Preparation method of nickel cobaltate/tungsten trioxide nanocomposite structure and its application in gas-sensitive coatings, components and sensors

A technology of tungsten trioxide and nanocomposite, applied in nickel oxide/nickel hydroxide, nickel compounds, chemical instruments and methods, etc., to achieve good selectivity, good reversibility, rapid and high-sensitivity detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

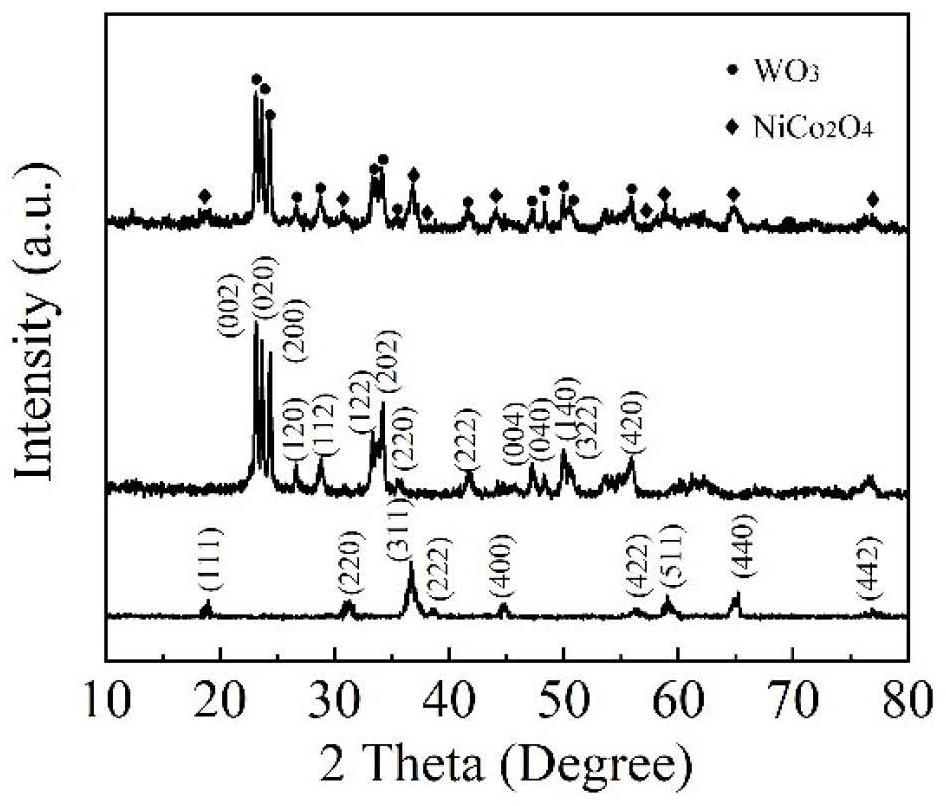

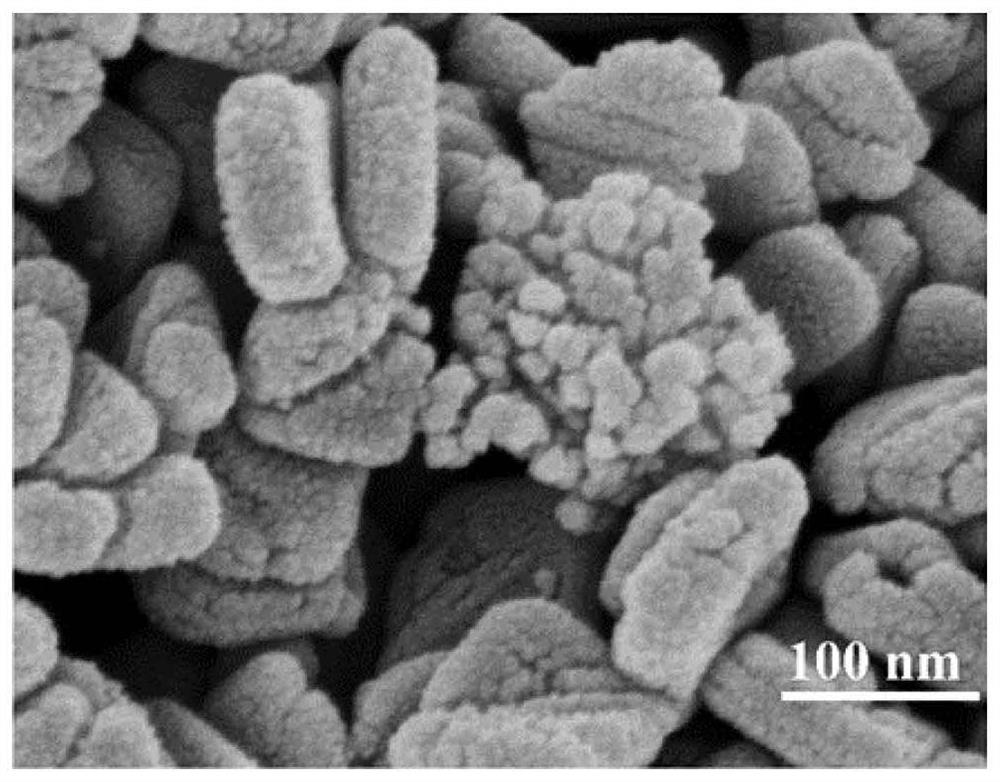

[0052] A nickel cobaltate / tungsten trioxide nanocomposite structure, the composite material is NiCo formed by orderly self-assembly of nanospheres 2 O 4 Nanoflower modified WO 3 nanoplates,

[0053] the WO 3 It is a nanoplate with a cubic phase crystal structure, and the surface is rough and has obvious cracks;

[0054] The NiCo 2 O 4 Nanomaterials are nanoflower-like spinel crystal structures composed of nanospheres.

[0055] the WO 3 The nanoplates have a length of 100-200 nm, a width of 100-200 nm and a thickness of 10-20 nm;

[0056] The NiCo 2 O 4 The diameter of the nanoflowers is 150–250 nm, and the NiCo 2 O 4 The diameter of the nanospheres is 30–50 nm.

[0057] A method for preparing a nickel cobaltate / tungsten trioxide nanocomposite structure,

[0058] ①Mix 0.60~0.75 g of NiCl 2 ·6H 2 O and 1.40~1.50 g of CoCl 2 ·6H 2 Put O into 60 mL of deionized water, stir vigorously for 10-20 min to completely dissolve it, add 0.50-0.6 g of urea and stir vigorous...

Embodiment 2

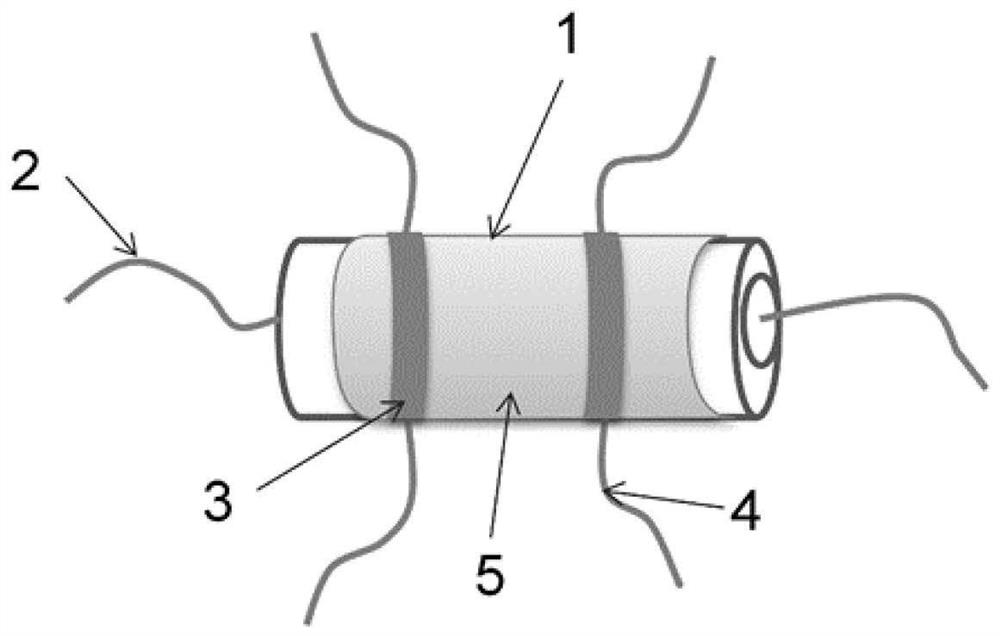

[0085] A gas-sensitive coating is NiCo assembled from nanospheres 2 O 4 Nanoflower modified WO 3 The gas sensor of the nanoplate, its structure diagram is as follows figure 1 shown in which the Ni-Cr heating wire 2 traverses the Al 2 O 3 Ceramic tube 1 and welded on the heating electrode of the hexagonal base, gold electrode 3 coated with Al 2 O 3 The outer surface of the ceramic tube 1 is welded to the measuring electrode of the hexagonal base through four platinum wires 4, and the gas-sensitive coating 5 is coated on the outer surface of the gold electrode 3 and the ceramic tube 1. The composition of the coating 5 is NiCo assembled from nanospheres 2 O 4 Nanoflower modified WO 3 Nanoplates, the WO 3 The nanoplate has a cubic phase crystal structure, the length of the nanoplate is 100-200 nm, the width is 100-200 nm, and the thickness is 10-20 nm. The NiCo 2 O 4 The nanoflower has a spinel crystal structure, the diameter of the nanoflower is 150-250 nm, and the dia...

Embodiment 3

[0100] A synthesis of NiCo assembled from nanospheres by secondary hydrothermal generation 2 O 4 Nanoflower modified WO 3 Preparation method and NO of nanoplate 2 Gas sensor, follow the steps below:

[0101] ①Mix 0.60 g NiCl 2 ·6H 2 O and 1.40 g CoCl 2 ·6H 2 O was placed in 60 mL of deionized water, and after vigorous stirring for 10 min to completely dissolve it, 0.50 g of urea was added and vigorously stirred for 0.5 h.

[0102] ② Put the precursor solution obtained in step ① in a 100 mL PTFE autoclave at 100 o After heating at C for 10 h, a lavender precipitated product was obtained.

[0103]③ Wash the lavender precipitated product obtained in step ② alternately with deionized water and absolute ethanol for 6 times, and at 60 o Dry at C for 8 h, and then place the dried product at 300 o Heat treatment at C for 1 h.

[0104] ④The NiCo obtained in step ③ 2 O 4 Nanoflower and 1.0 g Na 2 WO 4 ·2H 2 O, 1.5 mL of lactic acid was added to 50 mL of deionized water, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com