Novel antibacterial and antiviral preparation, resin, decorative paper and plate

An antiviral and new technology, applied in the fields of decorative paper and board, resin, new antibacterial and antiviral preparations, can solve the problems of low crushing efficiency, unable to meet the diameter requirements, etc., achieve strong sterilization ability, improve sterilization and disinfection effect, and significantly economical effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

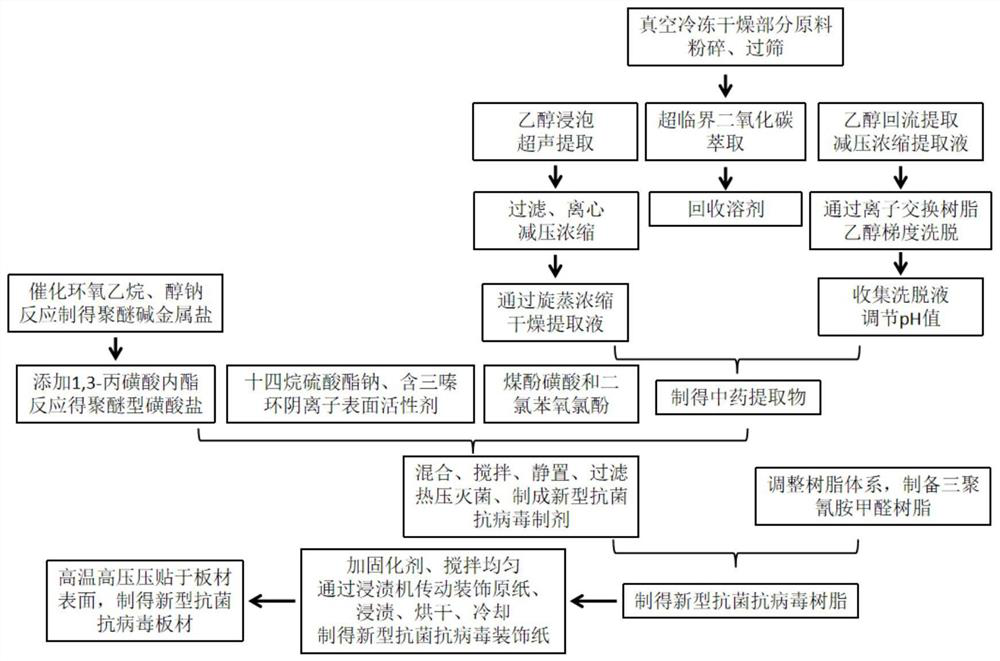

[0093] Preparation of novel antibacterial and antiviral preparations:

[0094] 1) Polyether sulfonate

[0095] (1) Ethylene oxide, sodium alkoxide, and catalyst are placed in the reactor, and the reaction temperature is controlled to be 35-40° C. to initiate the reaction;

[0096] (2) Keep the temperature of the reactor constant, control the reaction to proceed forward, and increase the chain reaction to obtain the polyether alkali metal salt;

[0097] (3) Dehydrate the polyether alkali metal salt and the catalyst, place it in the reactor and adjust the temperature of the reactor to 55-60°C, add 1,3-propane sultone to the reactor to keep the polyether alkali metal The molar ratio of salt, catalyst, and 1,3-propane sultone is 1:0.02-0.06:1.0-1.2, and the polyether sulfonate is obtained through reaction;

[0098] synthetic route:

[0099] 1.

[0100] 2.

[0101] 3.

[0102] 2) Plant extracts

[0103] Extract A:

[0104] (1) Angelica dahurica and Atractylodes atractyl...

Embodiment 2

[0120] Preparation of novel antibacterial and antiviral resins:

[0121] A. Synthetic nonionic resin

[0122] (1) Add 17% deionized water, 44% formaldehyde solution (wt=37%), and 3% diethylene glycol to a clean reactor in sequence, mix well, and then add lye to adjust the pH The value is 8.5-10.5;

[0123] (2) Adding melamine with a mass percentage of 36% in the kettle, stirring and reacting for 5-10min;

[0124] (3) Heating the reaction kettle to 95°C at 5°C / min, keeping the temperature of the reaction kettle at 80-95°C, and continuously stirring and reacting for 30-90min to prepare the melamine formaldehyde resin;

[0125] The structural general formula of described melamine formaldehyde resin is:

[0126] B. Preparation of new antibacterial and antiviral resins

[0127] The above-mentioned melamine formaldehyde resin is cooled, and when the temperature drops to 40° C., a new antibacterial and antiviral preparation with a mass percentage of 5% is added, and the mixture i...

Embodiment 3

[0129] Preparation of novel antibacterial and antiviral decorative paper:

[0130] (1) adding the curing agent that mass percentage is 5 ‰ in the novel antibacterial and antiviral resin that prepares, stir rapidly;

[0131] (2) Drive the decorative base paper through the driving roller of the impregnation machine, control the machine running line speed to 20-30m / min, keep the decorative base paper fully immersed in the first dip, drive it to the oven, and adjust the oven temperature to 110°C;

[0132] (3) Transfer to the second impregnation, control the total amount of glue to be 120±5g, and then transfer to the oven for the second drying, and adjust the oven temperature to 135°C;

[0133] (4) After drying in a second-stage oven, dehumidify and cool to about 50°C, cut and pack according to the required size, and obtain a new type of antibacterial and antiviral decorative paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com