Carbonyl-containing tetraphenylpyrrole derivative as well as preparation method and application thereof

A technology of tetraphenylpyrrole derivatives, which is applied in the field of carbonyl-containing tetraphenylpyrrole derivatives and its preparation, can solve the problems of poor stability, decreased battery cycle capacity, and decreased theoretical specific capacity of polymers. Achieve the effect of simple operation and concise synthesis route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

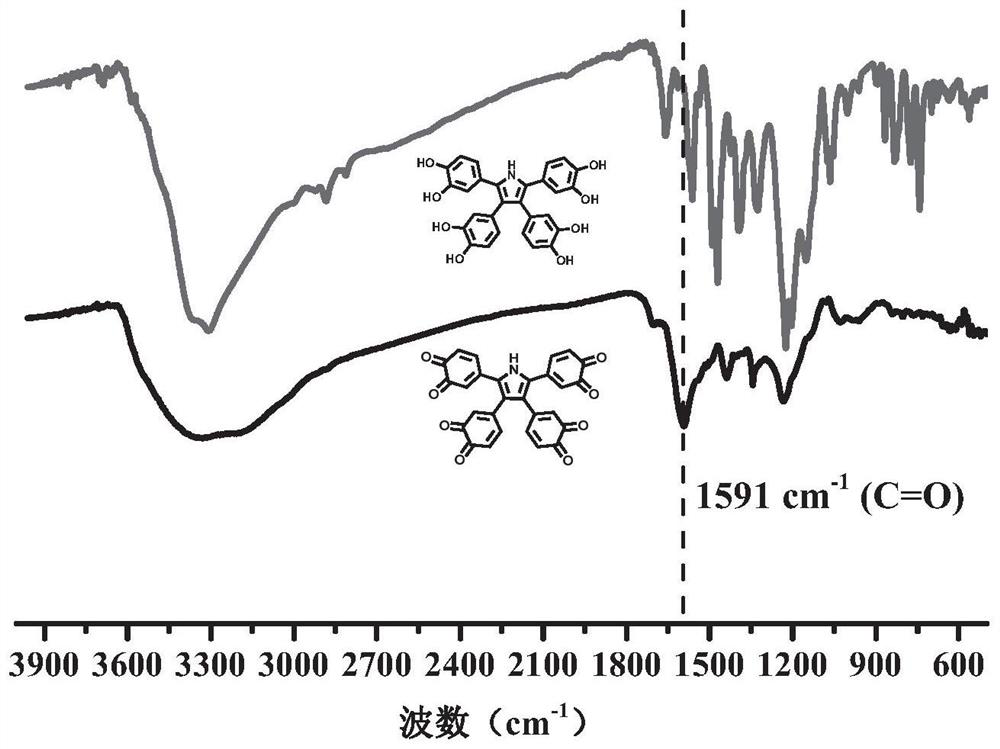

[0027] Another aspect of the embodiments of the present invention also provides a preparation method based on carbonyl-containing tetraphenylpyrrole derivatives, which includes:

[0028] (1) Reflux the first homogeneously mixed reaction system comprising 1,2-bis(3,4-dimethoxyphenyl)ethanone, silver fluoride and the first solvent at 130-150°C until the raw material consumption is complete ; Removing the first solvent to obtain a mixed solid, reacting at 110-130° C. for 10-15 hours from the second uniform mixed reaction system of the mixed solid and ammonium acetate, and obtaining a methoxy-containing tetraphenylpyrrole derivative after purification;

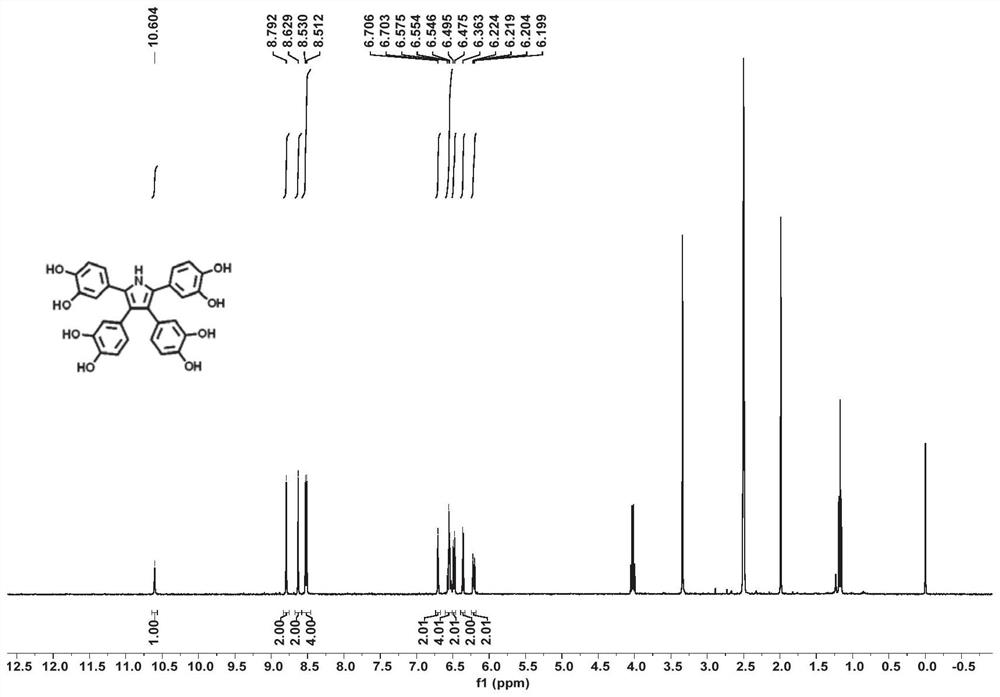

[0029] (2) The third homogeneous mixed reaction system comprising the methoxy-containing tetraphenylpyrrole derivative, boron tribromide and dichloromethane was stirred overnight at -78°C, quenched with distilled water, and purified to obtain Hydroxy tetraphenylpyrrole derivatives;

[0030] (3) Under a protective atmosphere, stir...

Embodiment 1

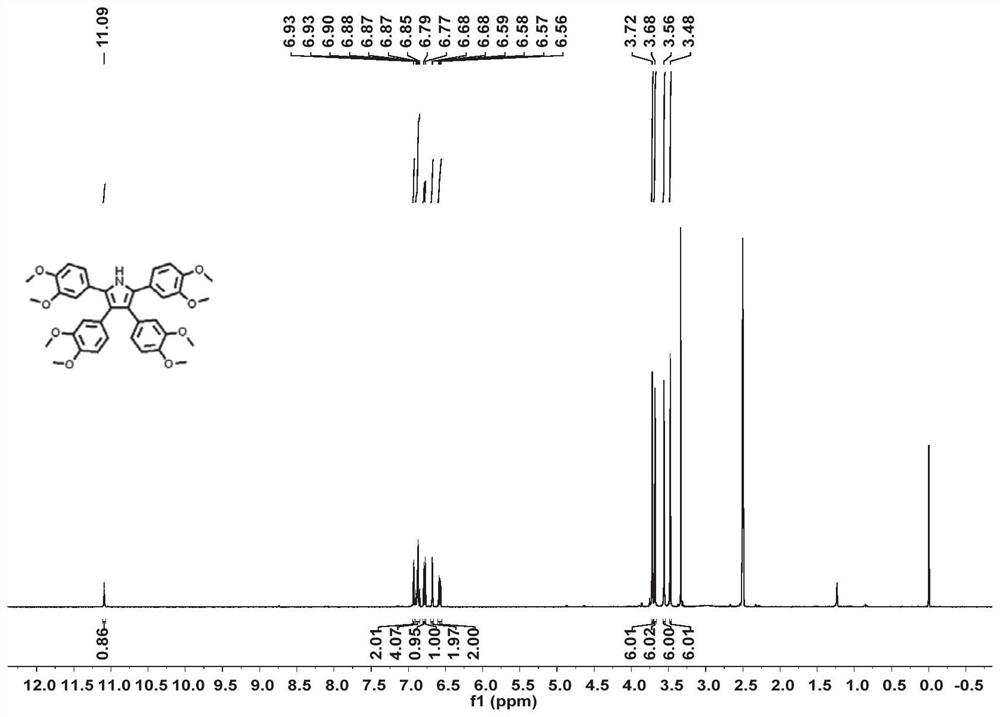

[0058] (1) Synthesis of 2,3,4,5-tetra(3,4-dimethoxyphenyl)-1H-pyrrole:

[0059]

[0060] A mixed reaction system containing 1,2-bis(3,4-dimethoxyphenyl)ethanone (3.16 g, 10 mmol), AgF (128 mg, 1 mmol) and xylene (30 mL) was heated at 130 Stir and reflux at ~150°C until consumption of starting material is complete; a mixture is obtained after removal of solvent. Subsequently, ammonium acetate (7.70 g, 100 mmol) was added to the obtained mixture, and stirred at 110-130° C. for 10-15 h. After the reaction was complete, the mixture was extracted with dichloromethane and saturated brine, and the organic layer was separated, dried over anhydrous sodium sulfate, and concentrated to obtain a crude product. The crude product was purified by silica gel column chromatography, and the eluents used were ethyl acetate and petroleum ether. After purification, 0.78 g of white powder was obtained with a yield of 26%. Its NMR spectrum is as figure 1 as shown, 1 H NMR (400MHz, DMSO-d 6 )...

Embodiment 2

[0068] Preparation of the lithium-ion battery pole piece based on the carbonyl-containing tetraphenylpyrrole derivative:

[0069] Weigh 20 mg of carbonyl-containing tetraphenylpyrrole derivatives, 16 mg of multi-walled carbon nanotubes, and 160 mg of polyvinylidene fluoride (PVDF, the concentration of PVDF in N-methylpyrrolidone is 2.5 wt%) viscous prepared in Example 1. The binder and a certain amount of N-methylpyrrolidone (NMP) are mixed, and the mixture is put into a ball mill for 2-3 hours and mixed evenly, and then the sample mixed in the ball mill container is coated on the current collector Al foil to a thickness of 200-250 μm Thick film, dry at 70-80°C for 12-24h, cut the dried electrode sheet into a circular battery pole piece with a diameter of 14mm, to obtain the lithium-ion battery based on the carbonyl-containing tetraphenylpyrrole derivative pole piece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com