Biocompatible antibacterial film and preparation method thereof

A technology of biocompatibility and thin film, which is applied in the field of biocompatible antibacterial film and its preparation, can solve the problems of poor water barrier rate, limited application, poor mechanical properties, etc., and achieve antibacterial and elongation at break, preparation The effect of simple process and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of biocompatible antibacterial film and preparation method thereof

[0030] Biocompatible antibacterial film, the biocompatible antibacterial film comprises the following components by mass: modified polyvinyl alcohol 60g, starch 25g; modified chitosan 25g; capsaicin 4gg, glycerin 12gg.

[0031] The preparation of above-mentioned modified chitosan comprises the following steps:

[0032] S1, at room temperature, dissolve chitosan in distilled water, add 6% acetic acid solution dropwise to adjust the pH to 4, stir at 45°C for 30 minutes to dissolve chitosan evenly, and obtain a shell with a concentration of 1.5wt%. Polysaccharide solution: Dissolve glycidyltrimethylammonium chloride in distilled water, stir magnetically to dissolve glycidyltrimethylammonium chloride evenly, and obtain glycidyltrimethylammonium chloride with a concentration of 0.2mol / L ammonium chloride solution;

[0033] S2, Slowly add glycidyltrimethylammonium chloride solution to the chitosan s...

Embodiment 2

[0039] A kind of biocompatible antibacterial film and preparation method thereof

[0040] Biocompatible antibacterial film, the biocompatible antibacterial film comprises the following components by mass: modified polyvinyl alcohol 65g, starch 28g; modified chitosan 30g; capsaicin 5g, glycerin 14g.

[0041] The preparation of above-mentioned modified chitosan comprises the following steps:

[0042] S1, at room temperature, dissolve chitosan in distilled water, add dropwise 6% acetic acid solution to adjust the pH to 4, stir at 45°C for 35min, dissolve chitosan evenly, and obtain a shell with a concentration of 1.8wt%. Polysaccharide solution: Dissolve glycidyltrimethylammonium chloride in distilled water, stir magnetically to dissolve glycidyltrimethylammonium chloride evenly, and obtain glycidyltrimethylammonium chloride with a concentration of 0.3mol / L ammonium chloride solution;

[0043] S2, Slowly add glycidyltrimethylammonium chloride solution to the chitosan solution d...

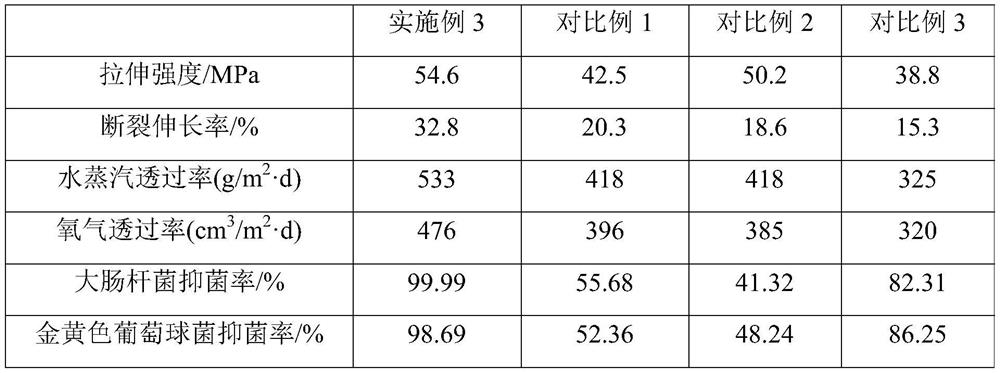

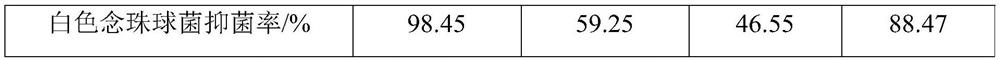

Embodiment 3

[0049] A kind of biocompatible antibacterial film and preparation method thereof

[0050] Biocompatible antibacterial film, the biocompatible antibacterial film comprises the following components by mass: modified polyvinyl alcohol 70g, starch 300g; modified chitosan 40g; capsaicin 8g, glycerin 20g.

[0051] The preparation of above-mentioned modified chitosan comprises the following steps:

[0052] S1, at room temperature, dissolve chitosan in distilled water, add dropwise 6% acetic acid solution to adjust the pH to 5, stir at 55°C for 35min, dissolve chitosan evenly, and obtain a shell with a concentration of 2.5wt%. Polysaccharide solution: Dissolve glycidyltrimethylammonium chloride in distilled water, and magnetically stir to dissolve glycidyltrimethylammonium chloride evenly to obtain glycidyltrimethylammonium chloride with a concentration of 0.6mol / L ammonium chloride solution;

[0053] S2, slowly drop glycidyltrimethylammonium chloride solution into the chitosan solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com