Preparation method of composite particles wrapping quorum sensing inhibitor and product thereof

A quorum sensing and composite particle technology, which is applied to non-active ingredients in medical preparations, pharmaceutical formulations, active ingredients of hydroxyl compounds, etc. Better quorum sensing activity, improved encapsulation efficiency and stability, and reduced transport resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] This example provides a preparation method for encapsulating quorum sensing inhibitor composite particles:

[0063] (1) Add sodium alginate to deionized water at 60°C, stir until completely dissolved to obtain an aqueous solution of sodium alginate; add montmorillonite powder to the aqueous solution of sodium alginate, mix well, and lower to 25°C, Stir for 1 hour, let it stand overnight to discharge air bubbles, and prepare a mixed solution of montmorillonite and sodium alginate, which is used as an aqueous phase for later use, wherein the mass fraction of montmorillonite is 2wt%, and the mass fraction of sodium alginate is 2wt%;

[0064] (2) Take monoglyceride stearate and heat it at 65°C to dissolve, add carvacrol after it is completely dissolved, and mix the two evenly as the oil phase, wherein the mass ratio of monoglyceride stearate to carvacrol is 2 :1;

[0065] (3) Heat the water phase prepared in (1) to 70°C, pour it into the beaker containing the oil phase in ...

Embodiment 2

[0070] Under the conditions of Example 1, the control conditions are: MMT (montmorillonite) content is 2% (w / w), Alg (sodium alginate) content is 2% (w / w), oil: carvacrol ( (mass ratio)=2:1, the oil-water ratio is (volume ratio) 1:5, other conditions are the same as embodiment 1, when exploring the oil phase is respectively liquid paraffin, beeswax and GMS (monoglycerol stearate) to microparticle preparation influences.

[0071] see results figure 1 .

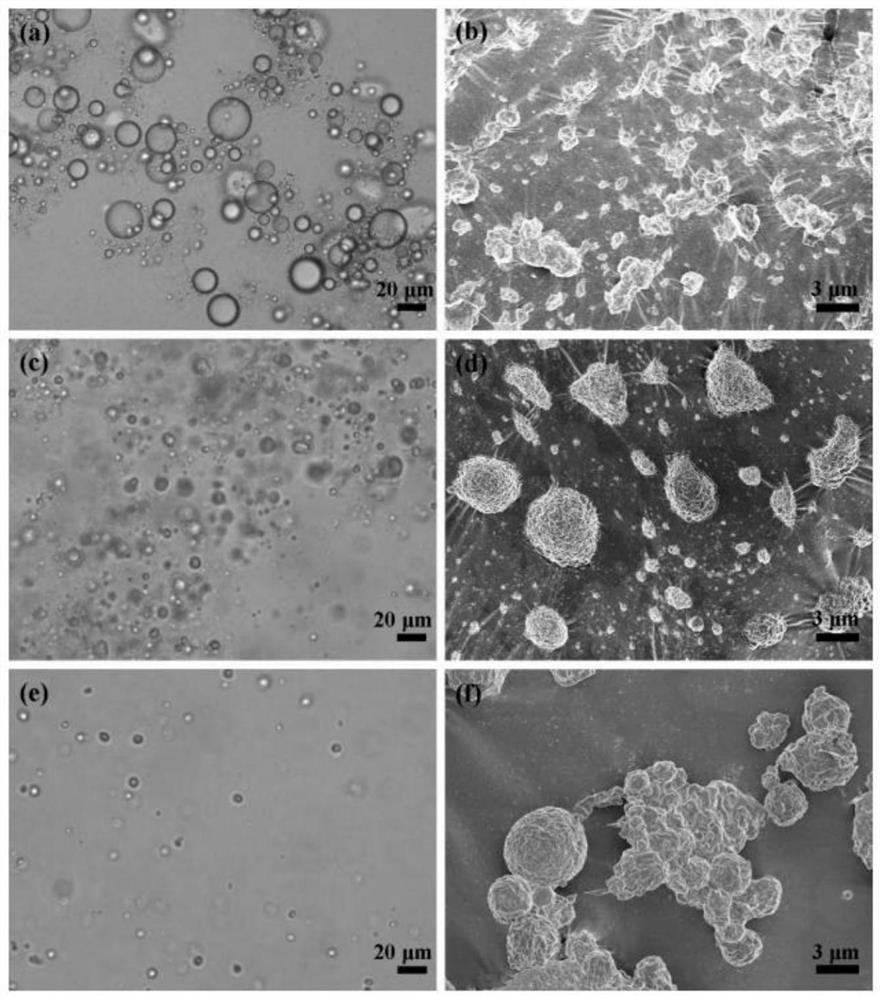

[0072] figure 1 (a) and (b) are micrographs and SEM images of Pickering emulsions prepared using liquid paraffin as the oil phase. It can be seen that the particle size of the emulsion is about 20 μm, and the particle size difference after curing is large, and there is no fixed shape. This is because the preparation process of the microparticles needs to go through a large number of steps such as dilution, stirring, and centrifugation. The Pickering emulsion prepared by liquid paraffin will break and coalesce. More oil phas...

Embodiment 3

[0078] The influence of Alg mass fraction: under the condition of embodiment 1, control condition is: MMT (montmorillonite) content is 2% (w / w), GMS: carvacrol=2:1, oil-water ratio is 1:5 When the mass fraction of Alg was 1%, 1.5%, 2.0%, and 2.5%, the influence on the preparation of microparticles was studied, and other conditions were the same as in Example 2.

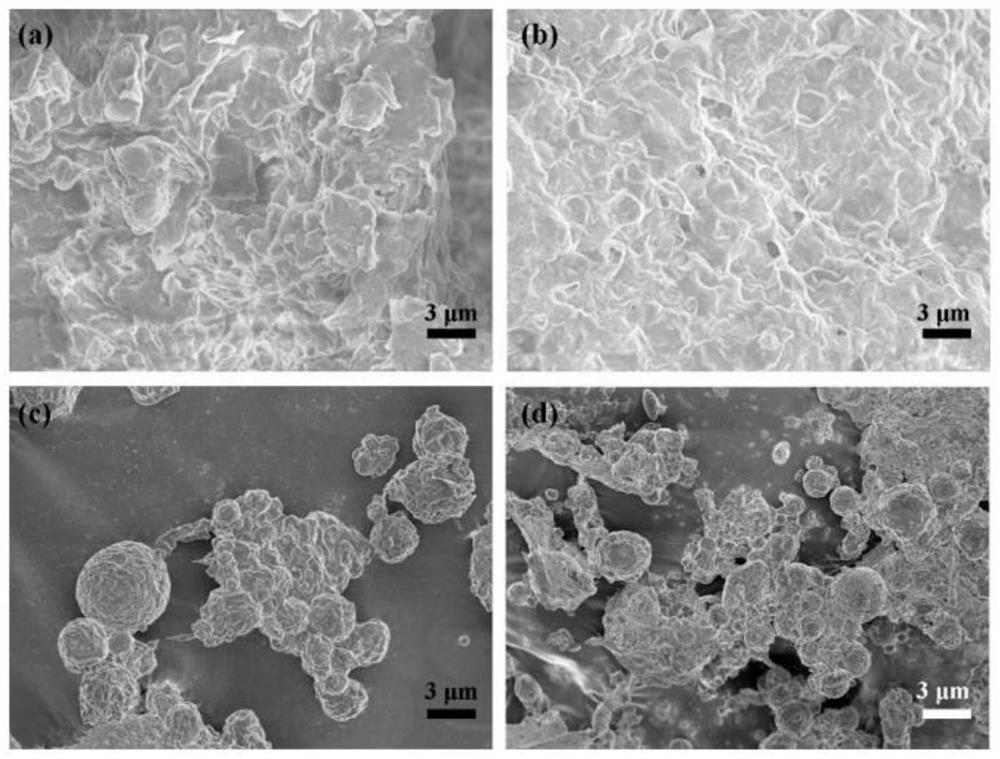

[0079] see results figure 2 , wherein, (a) is 1.0%, (b) is 1.5%, (c) is 2.0%, and (d) is the electron micrograph of 2.5%.

[0080] It can be seen that when the Alg content is low, there is not enough Alg and Ca 2+ Cross-linking will cause part of the shell layer of the solidified particle to not solidify into a network shape or the shell layer is thin, so that the outside of the particle does not have enough hardness and rigidity to resist external forces. Moreover, the fragile shell layer may be broken during solidification and dispersion, and the oil phase cannot be well wrapped, and a large number of particles a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com