Selective photodegradable acid orange molecularly imprinted polymer, preparation method and application thereof

A molecularly imprinted, acid orange technology, applied in the field of visible light catalysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method for selectively photodegrading acid orange molecularly imprinted polymers, comprising the following steps:

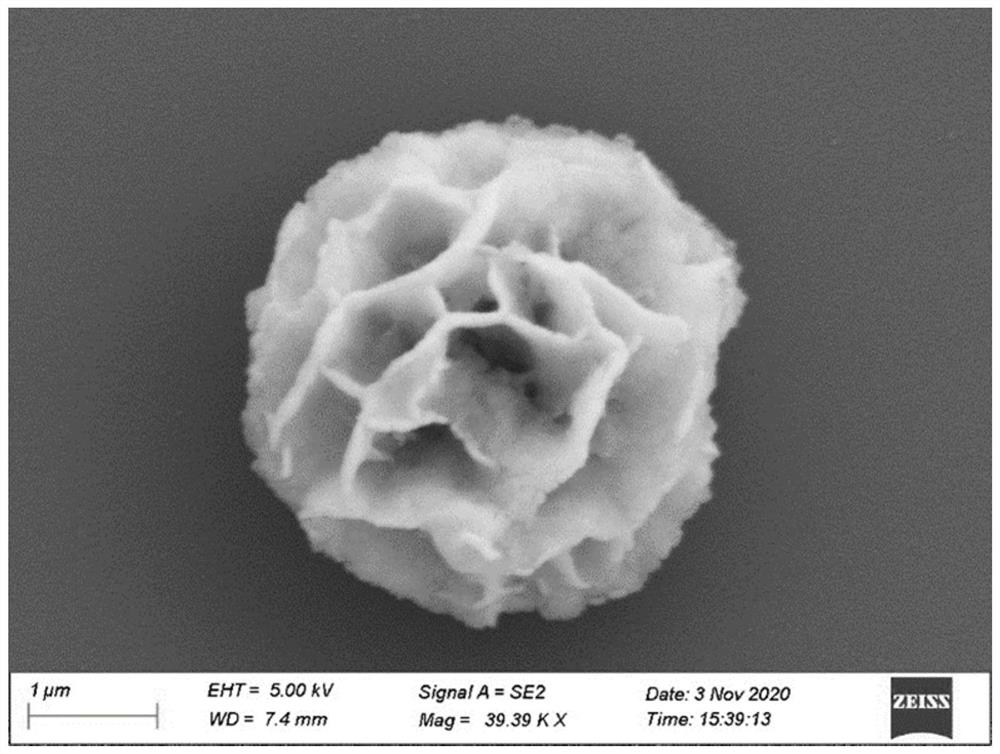

[0033] 1) Put 10mg of bismuth nitrate pentahydrate, 5mg of potassium bromide, 2mg of copper nitrate trihydrate and 0.5g of polyvinylpyrrolidone in a reaction kettle, add 40mL of ethylene glycol, and react at a temperature of 100°C for 6 hours. , the reaction product was washed, dried, and vacuum-dried at 20° C. and 0.02 MPa for 4 hours to prepare bismuth oxybromide microspheres. Such as figure 1 As shown, the prepared bismuth oxybromide microspheres are petal-shaped, and the particle size is about 3.5 μm.

[0034] 2) Add 50 mg of bismuth oxybromide microspheres, 10 mg of acid orange and 5 mL of ultrapure water into a three-necked flask, and mechanically stir for 30 min at room temperature. Mix 10 μL of pyrrole, 50 μL of trimethylolpropane trimethacrylate, 10 mg of azobisisobutyronitrile and 0.5 mL of chloroform solution, add them to the abo...

Embodiment 2

[0045] A preparation method for selectively photodegrading acid orange molecularly imprinted polymers, comprising the following steps:

[0046] 1) Put 30mg of bismuth nitrate pentahydrate, 20mg of potassium bromide, 2.7mg of copper nitrate trihydrate and 1.0g of polyvinylpyrrolidone in a reaction kettle, add 60mL of ethylene glycol, and react at a temperature of 180°C for 7h, and the reaction ends Afterwards, the reaction product was washed, dried, and vacuum-dried at 30° C. and 0.05 MPa for 5 hours to prepare bismuth oxybromide microspheres.

[0047] 2) Add 125 mg of bismuth oxybromide microspheres, 25 mg of acid orange and 25 mL of ultrapure water into a three-necked flask, and mechanically stir for 30 min at room temperature. Mix 60 μL of pyrrole, 90 μL of trimethylolpropane trimethacrylate, 50 mg of azobisisobutyronitrile and 1 mL of chloroform solution into the above-mentioned three-necked flask, blow nitrogen gas for 15 minutes, and set the temperature at 75°C. Heated t...

Embodiment 3

[0058] A preparation method for selectively photodegrading acid orange molecularly imprinted polymers, comprising the following steps:

[0059] 1) Put 15mg of bismuth nitrate pentahydrate, 15mg of potassium bromide, 3.2mg of copper nitrate trihydrate and 1.5g of polyvinylpyrrolidone in a reaction kettle, add 50mL of ethylene glycol, and react at a temperature of 120°C for 9h, and the reaction ends Afterwards, the reaction product was washed, dried, and vacuum-dried at 50° C. and 0.04 MPa for 8 hours to prepare bismuth oxybromide microspheres.

[0060] 2) Add 150 mg of bismuth oxybromide microspheres, 15 mg of acid orange and 40 mL of ultrapure water into a three-necked flask, and mechanically stir for 30 min at room temperature. Mix 120 μL of pyrrole, 200 μL of trimethylolpropane trimethacrylate, 30 mg of azobisisobutyronitrile and 2.5 mL of chloroform solution, then add them to the above-mentioned three-necked flask, blow nitrogen gas for 20 minutes, and set the temperature a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com