Black silicon manufacturing method based on mechanical grinding auxiliary corrosion

A technology of mechanical grinding and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as degraded device performance, low black silicon production capacity, and poor near-infrared absorption enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

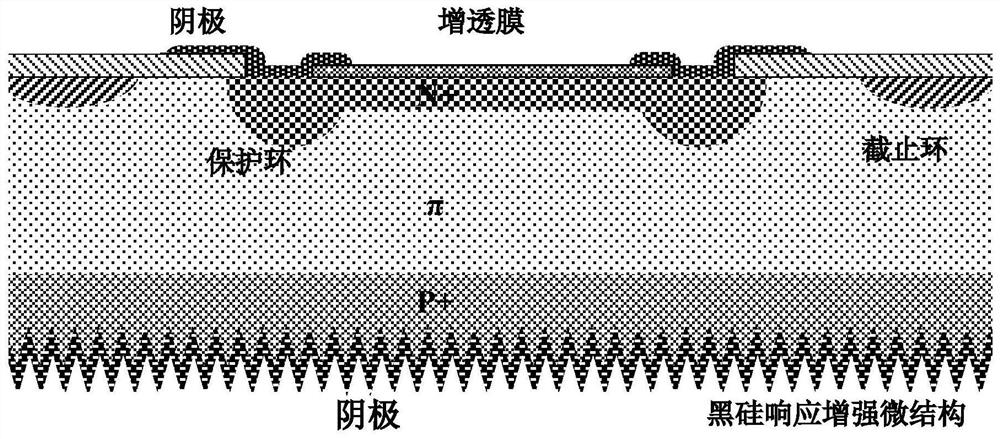

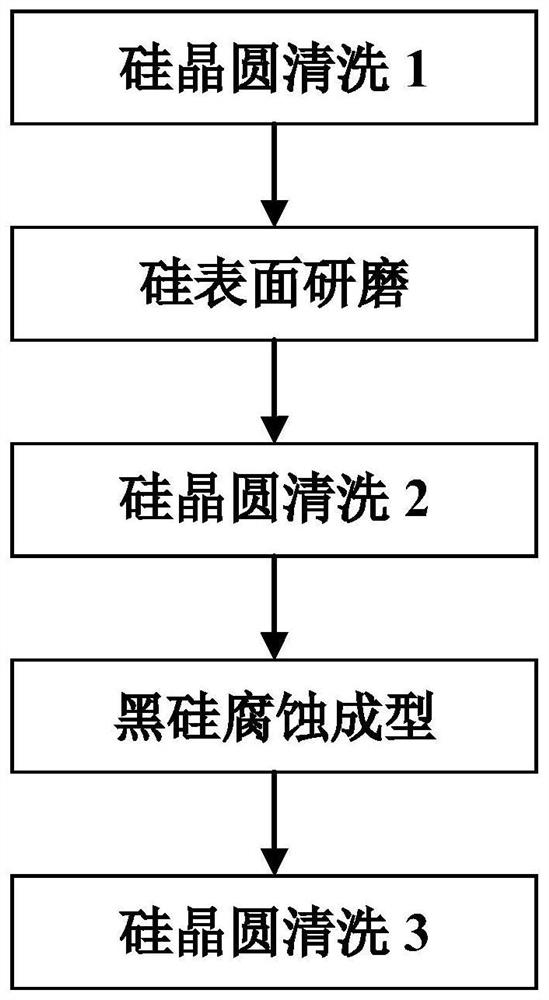

[0036] S0. Complete the fabrication of the front side process of the PIN / APD detector silicon wafer.

[0037] S1. Using an organic cleaning process to clean the wafer to remove surface contamination.

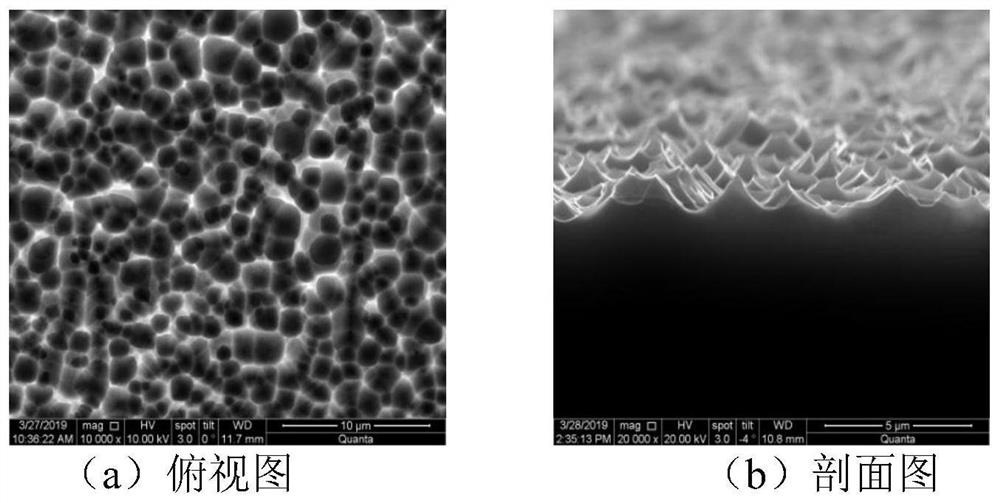

[0038] S2. Use a thinning pad containing corundum (diameter of corundum 0.5 μm ~ 9 μm) and a polishing solution (pH value 10 ~ 12) containing SiO2 abrasive (particle diameter 0.07 μm ~ 1 μm) to assist, and use a mechanical grinding process to process the back of the silicon wafer , produce rough surface and micro-damage on the back of the silicon wafer;

[0039] S3. Using an organic cleaning process to clean the silicon wafer;

[0040] S4, adopt the mixed liquor that comprises phosphoric acid, nitric acid, sulfuric acid and hydrofluoric acid, proportioning is (10%~25%): (20%~50%): (5%~25%): (1%~30%) ), etch the back of the silicon wafer to prepare a black silicon microstructure;

[0041] S5. Using an organic cleaning process to clean the silicon wafer to complete the preparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com