Method for preparing polyurethane-based composite electrolyte membrane and polyurethane-based composite electrolyte membrane

A composite electrolyte membrane and polyurethane technology, which is applied in composite electrolytes, circuits, electrical components, etc., can solve problems such as poor mechanical properties, difficulty in meeting the mechanical strength requirements of the diaphragm, weak ability to dissolve lithium salts and complex lithium ions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

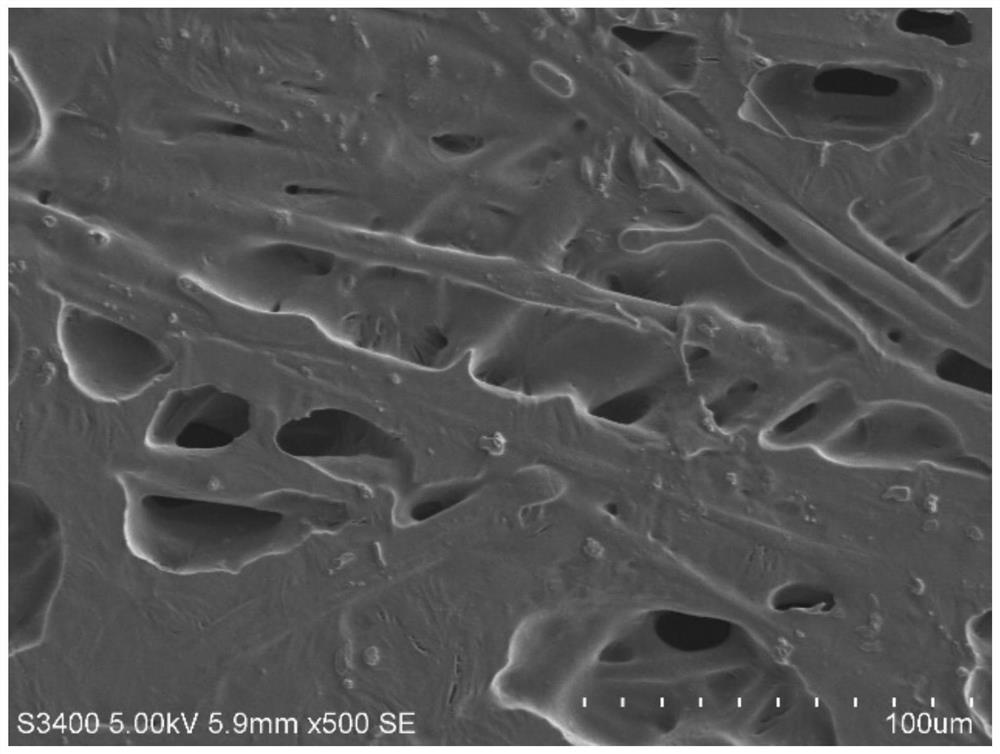

[0038] Step 3: After mixing the PU-PDMS copolymer prepared in the above step 2 and the mass ratio of 30% (30% of the mass of the mass of the PU-PDMS copolymer), add a twin screw extruder, extruded out The machine heating temperature was 170 ° C, the meltblown mold spray hole diameter was 0.4 mm, the mold temperature was 170 ° C, the hot air temperature was 200 ° C, the air pressure was 0.3 Ml, the flow rate was 4.5 ml / min. The reinforcing fiber material is PP, and the PP meltblown mold spine is 0.4 mm, the mold temperature is 250 ° C, the hot air temperature is 280 ° C, the air pressure is 0.3 Ml, PP melt flow rate 2 mL / min. The fiber wire ejected from the two modes is uniformly mixed in the air, and the rending distance of the die spinfiring pores will be 25cm, the receiving device is 80-120m / min, and the fiber diameter is At 1-5 μm.

[0039] Step 4: The mixed fiber filament passes through a pressure roll of 50-150 ° C, adjusting the pressure roller pressure and temperature...

Embodiment 2

[0042] Step 3: After mixing the PU-PDMS copolymer prepared in the above step 2 and the mass ratio of the lithium salt Litfsi of 30%, the double screw extruder is added, the extruder heating temperature is 170 ° C, the meltblown mold spray hole diameter is 0.4 MM, mold temperature 170 ° C, hot air temperature 200 ° C, gas pressure 0.3 MPa, and polymer flow of 4.5 ml / min. The PP meltblown mold spray hole is 0.4 mm, the mold temperature is 250 ° C, the hot air temperature is 280 ° C, the air pressure is 0.3 Ml, and the PP melt flow rate is 2 ml / min. The fiber wire ejected from the two turbines is uniformly mixed in the air, and the receiving device of the die spinheet pores will be 25 cm, the receiving device is 40-80 m / min, the fiber diameter is 1-5 μm.

[0043] Step 4: The mixed fiber filament passes through a pressure roll of 50-150 ° C, adjusting the pressure roller pressure and temperature, melting the polyurethane-polysiloxane-based polymer in the mixed fiber layer togeth...

Embodiment 3

[0045] Step 3: After mixing the PU-PDMS copolymer prepared in step 2 and the mass than 30% lithium salt grafsi is mixed and uniformly added to the twin screw extruder, the extruder heating temperature 150 ° C, the meltblown mold spine is 0.4mm The mold temperature is 150 ° C, the hot air temperature is 200 ° C, the air pressure is 0.3 MPa, and the polymer flow is 4.5 ml / min. The reinforcing fiber material is PP, and the PP meltblown mold spine is 0.4 mm, the mold temperature is 250 ° C, the hot air temperature is 280 ° C, the air pressure is 0.3 Ml, PP melt flow rate 2 mL / min. The fiber wire ejected from the two modes is uniformly mixed in the air, and the rending distance of the die spinfiring pores is 25 cm, the receiving device is 80-120 m / min, the fiber diameter is in the fiber diameter. 1-6 μm.

[0046] Step 4: The mixed fiber filament passes through a pressure roll of 50-150 ° C, adjusting the pressure roller pressure and temperature, melting the polyurethane-polysilox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Movement speed | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com