Preparation method of epsilon-polylysine-Arabic gum nanoparticles

A technology of polylysine and gum arabic, which is applied in food forming, food ingredients as antimicrobial preservation, food science, etc. It can solve the problem of improving the antibacterial ability and moisture absorption ability of ε-polylysine. solutions and other problems to achieve the effect of improving anti-moisture absorption capacity, moderate particle size and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation and characterization of ε-polylysine-gum arabic nanoparticles specifically include the following steps:

[0041] (1) Preparation of nanoparticles;

[0042] ① Raw material preparation: take ε-polylysine and gum arabic powder, dissolve and filter to obtain a dilution solution for later use;

[0043] ② Ionic cross-linking: ε-polylysine and gum arabic dilution, adjust the concentration ratio of the two to 1:4, pH to 5, place on a magnetic stirrer at room temperature and mix for 1 hour;

[0044] ③Heat induction: take the ε-polylysine-gum arabic solution after ion crosslinking, and heat it in a water bath at 90°C for 3 hours;

[0045] ④Ultrasonic: Take the heat-induced ε-polylysine-gum arabic solution, and ultrasonically crush it with a power of 500w for 10 minutes to prepare a nanoparticle solution;

[0046] ⑤Dried finished product: take the ε-polylysine-gum arabic nanoparticle solution after ultrasonication, freeze-dry it into powder under the conditions o...

Embodiment 2

[0070] The preparation and characterization of ε-polylysine-gum arabic nanoparticles specifically include the following steps:

[0071] (1) Preparation of nanoparticles;

[0072] The ε-polylysine-gum arabic nanoparticle solution was prepared according to the method in Example 1.

[0073] (2) Analysis of intermolecular forces;

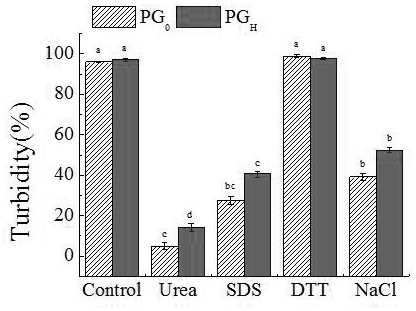

[0074] By measuring the turbidity, the turbidity changes of the nanoparticle solutions after different denaturant treatments were compared.

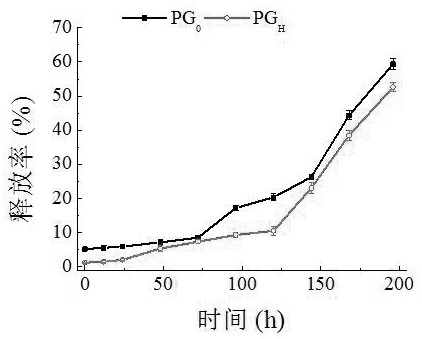

[0075] The result is as image 3 As shown, in the absence of denaturant, the prepared nanoparticles PG 0 、PG H The solution turbidity is higher, 94.3%, 95.5%. After adding denaturant, the PG of DTT treatment group 0 、PG H There was basically no change, while the turbidity of the urea, NaCl and SDS treatment groups changed significantly, and the turbidity was 4.6%, 27.5%, 39.3%, 14.1%, 40.6%, 52.4%, respectively; indicating that the nanoparticles PG 0 、PG H The main forces are hydrogen bonds, electrostatic...

Embodiment 3

[0083] The antibacterial experiment of epsilon-polylysine-gum arabic nanoparticles specifically includes the following steps:

[0084] (1) prepare bacterial liquid;

[0085] Salmonella was inoculated in LB liquid medium, and cultured with shaking at 200 rpm at 37°C for 24 hours to obtain a bacterial suspension in the logarithmic growth phase.

[0086] (2) Preparation of nanoparticles;

[0087] The ε-polylysine-gum arabic nanoparticle solution was prepared according to the method in Example 1.

[0088] (3) Determination of minimum inhibitory concentration (MIC) and minimum bactericidal concentration (MBC);

[0089]

[0090] The minimum inhibitory concentration and minimum bactericidal concentration were calculated for the four bacterial strains by using the microbroth dilution method, and the MIC was evaluated as the lowest ε-polylysine concentration that inhibited bacterial growth, and the MBC was evaluated as the lowest ε-polylysine concentration that completely killed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com