Polyether amine and preparation method and application thereof

A polyetheramine and polyether technology, which is applied in the field of polyetheramine of fuel detergent and its preparation, can solve the problems such as no polyetheramine, and achieve the advantages of inhibiting the formation of deposits, reducing by-products and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

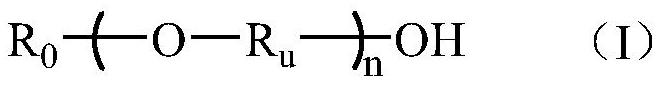

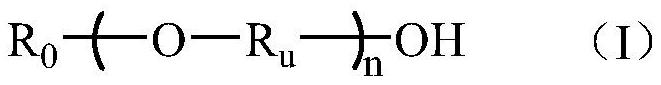

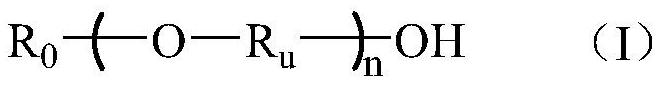

[0049] According to the first aspect of the present invention, the present invention provides a kind of preparation method of polyether amine, comprises the following steps:

[0050] Catalyst SO 4 -2 / ZrO 2 Adding it to polyether, and then adding epichlorohydrin to carry out epoxidation reaction to obtain a reaction solution;

[0051] Separation of the reaction liquid and recovery of catalyst SO 4 -2 / ZrO 2 And epichlorohydrin, obtains chlorohydrin intermediate product;

[0052] Adding a solid base to the chlorohydrin intermediate product to carry out a ring closure reaction to obtain a crude epoxy-terminated polyether;

[0053] After filtering the crude epoxy-based polyether, adding a neutralizing agent to the filtrate for neutralization, and then adding an adsorbent to obtain a refined epoxy-group-terminated polyether; and

[0054] Amination reaction of refined epoxy-terminated polyether with organic amine and / or inorganic ammonium to obtain polyether amine.

[0055]...

Embodiment 1

[0077] Embodiment 1 solid superacid catalyst SO 4 -2 / ZrO 2 preparation of

[0078] Weigh ZrOCl 2 ·8H 2 O 15g (accurate to 0.0001g) was dissolved in distilled water to make a saturated zirconium salt-water solution.

[0079] Under rapid stirring, dilute ammonia water with a volume fraction of 10% to 15% was added dropwise to adjust the pH of the solution to 9 to 10, left to age for 24 hours, filtered with suction, and washed with deionized water until the filtrate was washed with 0.1mol / L AgNO 3 The solution does not detect chloride ions.

[0080] Dry the filter cake for 12 hours, grind and sieve (1.05~1.5)×10 5 nm powder, soaked in sulfuric acid solution, filtered off the remaining solution, dried the powder, and baked in a muffle furnace for 3 hours to obtain a solid superacid catalyst SO 4 -2 / ZrO 2 .

Embodiment 2

[0081] The preparation of embodiment 2 polyetheramine

[0082] 1) Epoxidation of polyether.

[0083] 500g nonylphenol polyoxypropylene ether and 2.5g SO 4 -2 / ZrO 2 Add the catalyst into a 1000ml four-neck flask, start stirring under the protection of nitrogen, start to add 55.5g of epichlorohydrin dropwise after 10min, and complete the dropwise addition within 1h, raise the temperature to 60°C, and maintain this temperature for 2.5h.

[0084] After the reaction, the temperature was lowered to room temperature, the catalyst was separated by filtration, and epichlorohydrin was recovered by distillation under reduced pressure to obtain an intermediate product. Under nitrogen protection, 24 g of sodium hydroxide particles were added to the intermediate product, the temperature was raised to 40° C. for 3 hours, and the temperature was lowered to room temperature to obtain a crude epoxy-terminated polyether.

[0085] Collect the filtrate after filtering the crude epoxy-terminat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com