Preparation process of make-up base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

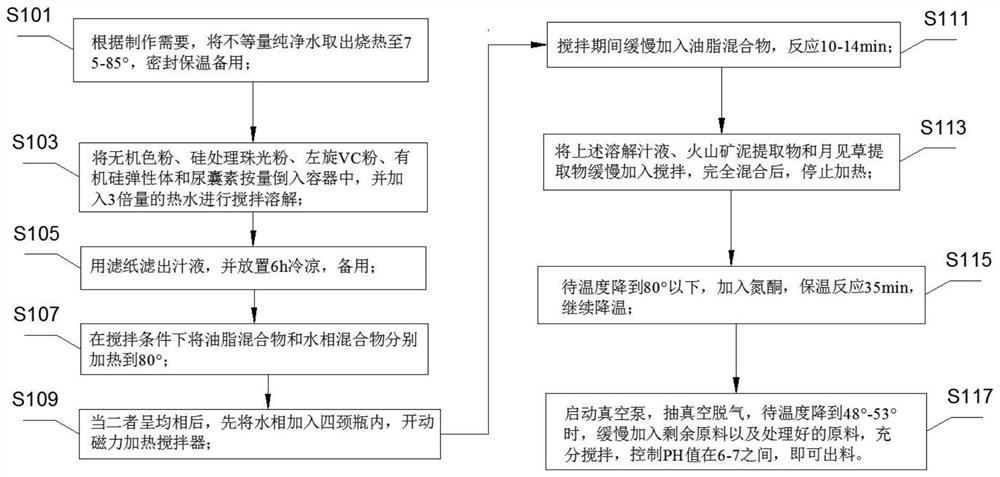

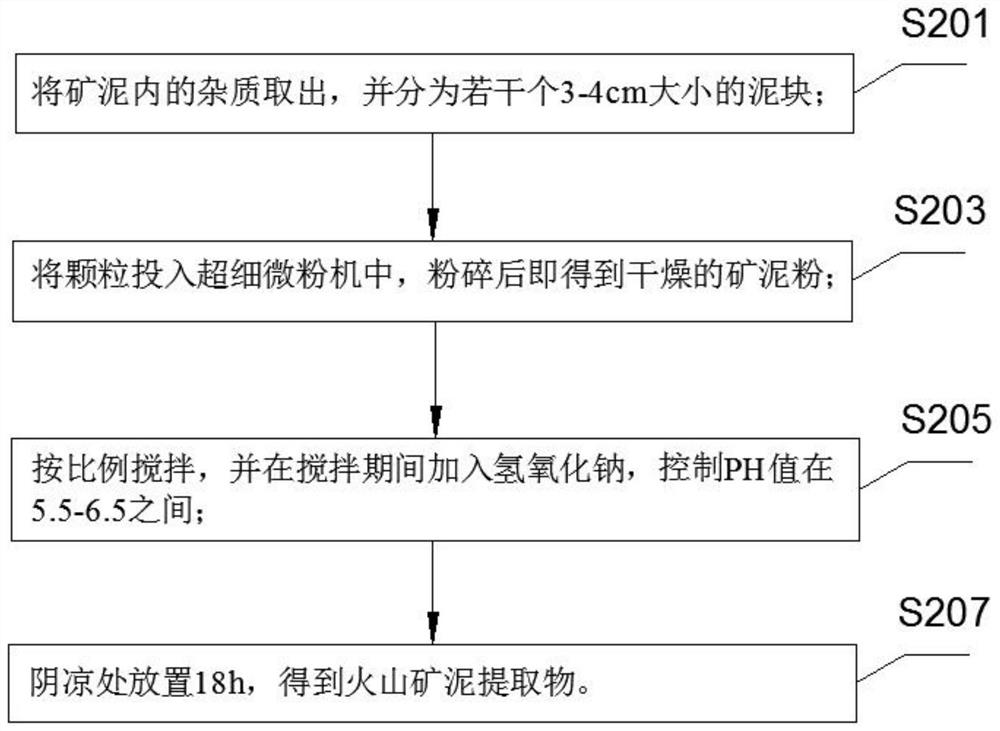

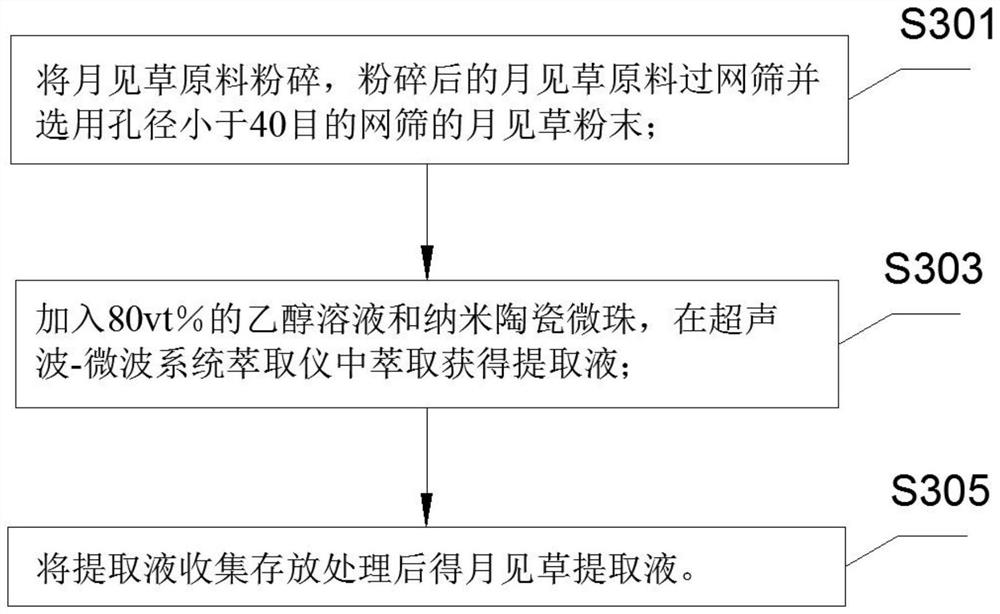

Method used

Image

Examples

Embodiment 1

[0058] A kind of segregation cream, this segregation frost comprises the raw material of following percentage number:

[0059] Oil mixture 28%, water phase mixture 17%, volcanic mud extract 10%, cold emulsifier 5%, essence 2%, left-handed VC powder 3%, antibacterial agent 1%, evening primrose extract 10%, 3% silicone elastomer, 2% azone, 1% inorganic toner, 3% preservative, 1% silicon treated pearl powder, 5% titanium dioxide, 1% allantoin, 1% methylparaben, propylparaben Esters 1%, Sodium Chloride Isononyl Isononanoate 1%, Squalene 1%, Iron Oxide Red 1%, and Hyaluronic Acid 1%.

[0060] Wherein, the oil mixture includes the following percentage raw materials: stearic acid 32%, cosmetic wetting agent 16%, emollient isopropyl palmitate 28%, moisturizer lanolin 1%, emulsifier 2%, preservative Parkin methyl ester 0.5% and propyl ester 0.1% and olive oil 5%.

[0061] Wherein, the water phase mixture includes the following percentage raw materials: moisturizing agent glycerin 60%...

Embodiment 2

[0063] A kind of segregation cream, this segregation frost comprises the raw material of following percentage number:

[0064] Oil mixture 32%, water phase mixture 21%, volcanic mud extract 12.5%, cold emulsifier 6%, essence 2.5%, left-handed VC powder 4%, antibacterial agent 2%, evening primrose extract 12.5%, 4% silicone elastomer, 3% azone, 2% inorganic toner, 4% preservative, 2% silicon treated pearl powder, 6.5% titanium dioxide, 2% allantoin, 2% methylparaben, propylparaben Esters 2%, Sodium Chloride Isononyl Isononanoate 2%, Squalene 2%, Iron Oxide Red 2%, and Hyaluronic Acid 2%.

[0065] Wherein, the oil mixture includes the following percentage raw materials: 33.5% stearic acid, 18% cosmetic wetting agent, 29% emollient isopropyl palmitate, 18% emollient lanolin, 2.5% emulsifier, preservative Parkin methyl ester 1% and propyl ester 0.3% and olive oil 6.5%.

[0066] Wherein, the water phase mixture includes the following percentages of raw materials: moisturizing age...

Embodiment 3

[0068] A kind of segregation cream, this segregation frost comprises the raw material of following percentage number:

[0069] Oil mixture 35%, water phase mixture 25%, volcanic mud extract 15%, cold emulsifier 7%, essence 3%, left-handed VC powder 5%, antibacterial agent 3%, evening primrose extract 15%, Silicone elastomer 3-5%, azone 2-4%, inorganic toner 3%, preservative 5%, silicon treated pearl powder 3%, titanium dioxide 8%, allantoin 3%, methylparaben 3% , propylparaben 3%, sodium chloride isononyl isononanoate 3%, squalene 3%, iron oxide red 1-3% and hyaluronic acid 3%.

[0070] Wherein, the oil mixture includes the following percentage raw materials: 35% stearic acid, 20% cosmetic wetting agent, 30% emollient isopropyl palmitate, 20% emollient lanolin, 3% emulsifier, preservative Parkin Methyl Ester 1.5% and Propyl Ester 05% and Olive Oil 8%.

[0071] Wherein, the aqueous phase mixture includes the following percentages of raw materials: moisturizing agent glycerin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com