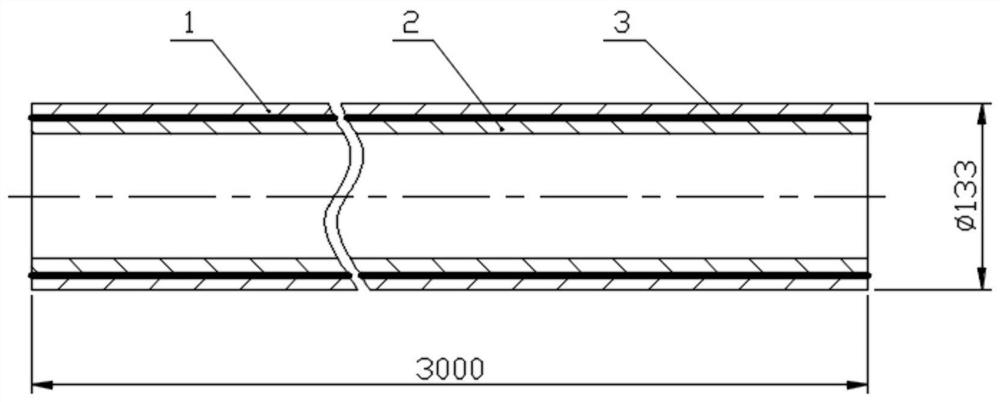

Solid double-metal inner wall wear-resistant material conveying circular pipe and preparation method thereof

A technology of bimetallic and circular pipes, applied in the field of solid bimetallic inner wall wear-resistant material conveying circular pipes and its preparation, to achieve the effects of high impact toughness, good sealing and corrosion resistance, and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] In the present Example 1, the metal jacket round pipe is a low carbon 20 rolled seamless steel pipe with a thickness of 2.1 mm.

[0064] The thickness of the metal inner sleeve round tube is: 3.2mm.

[0065] The raw materials for the metal inner sleeve round pipe are prepared according to the following parts by weight: 380 parts of carbon, 2,500 parts of chromium, 100 parts of manganese, 40 parts of molybdenum, 30 parts of nickel, 30 parts of vanadium, 50 parts of copper, 80 parts of silicon, and 80 parts of lanthanum. 3 parts, 3 parts cerium, 3 parts praseodymium, 3 parts neodymium, 3 parts promethium, 3 parts samarium, 3 parts europium, 3 parts gadolinium, 3 parts terbium, 3 parts dysprosium, 3 parts holmium, 3 parts erbium, 3 parts thulium , 3 parts of ytterbium, 3 parts of lutetium, 3 parts of yttrium, 2 parts of scandium, and 6740 parts of iron.

[0066] The preparation process is:

[0067] After mixing the raw materials of the metal inner sleeve round tube, heat...

Embodiment 2

[0073] In this embodiment 2, the metal jacket round pipe is a low carbon 20 rolled seamless steel pipe with a thickness of 2 mm.

[0074] The thickness of the metal inner sleeve round tube is: 3mm.

[0075] The raw materials for the metal inner sleeve round pipe are prepared according to the following parts by weight: 370 parts of carbon, 2,450 parts of chromium, 90 parts of manganese, 35 parts of molybdenum, 25 parts of nickel, 25 parts of vanadium, 40 parts of copper, 70 parts of silicon, and 70 parts of lanthanum. 3 parts, 3 parts cerium, 3 parts praseodymium, 3 parts neodymium, 3 parts promethium, 3 parts samarium, 3 parts europium, 3 parts gadolinium, 3 parts terbium, 3 parts dysprosium, 3 parts holmium, 2 parts erbium, 2 parts thulium , 2 parts of ytterbium, 2 parts of lutetium, 2 parts of yttrium, 2 parts of scandium, 6850 parts of iron.

[0076] The preparation process is:

[0077] After mixing the raw materials of the metal inner sleeve round tube, heat it to 1620 ℃...

Embodiment 3

[0082] In this Example 3, the metal jacket round pipe is a low carbon 20 rolled seamless steel pipe with a thickness of 1.8 mm.

[0083] The thickness of the metal inner sleeve round tube is: 2.8mm.

[0084] The raw materials for the metal inner sleeve round pipe are prepared according to the following parts by weight: 360 parts of carbon, 2,400 parts of chromium, 80 parts of manganese, 30 parts of molybdenum, 20 parts of nickel, 20 parts of vanadium, 30 parts of copper, 60 parts of silicon, and lanthanum 3 parts, 3 parts cerium, 3 parts praseodymium, 3 parts neodymium, 3 parts promethium, 3 parts samarium, 2 parts europium, 2 parts gadolinium, 2 parts terbium, 2 parts dysprosium, 2 parts holmium, 2 parts erbium, 2 parts thulium , 2 parts of ytterbium, 2 parts of lutetium, 2 parts of yttrium, 2 parts of scandium, 6960 parts of iron.

[0085] The preparation process is:

[0086] After mixing the raw materials of the metal inner sleeve round tube, heat it to 1580 ℃ to reach a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com