Preparation method of monatomic platinum composite electrocatalytic hydrogen evolution material

An electrocatalytic and atomic technology, applied in the direction of electrodes, electrolytic components, electrolytic processes, etc., can solve problems such as platinum agglomeration and hinder the stability of SACs, achieve the effect of reducing the dosage, increasing the active specific surface area, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

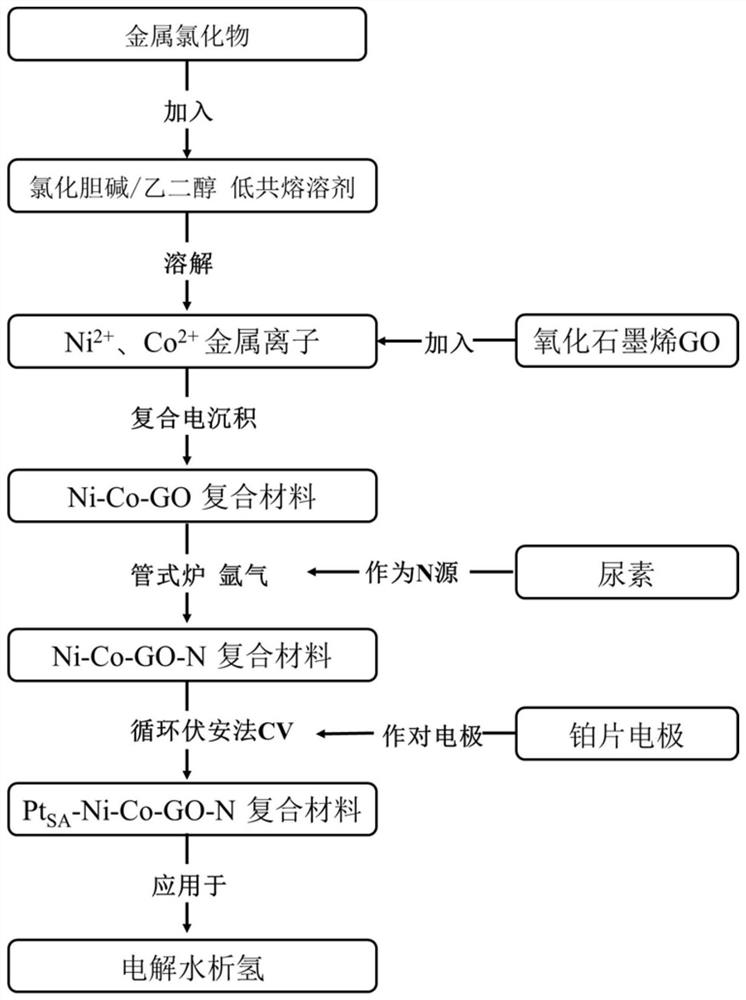

[0053] In this example, a method for preparing single-atom platinum composite electrocatalytic hydrogen evolution materials by controllable dissolution of platinum electrodes is mainly introduced. The process flow is as follows: figure 1 As shown, the specific operation steps are as follows:

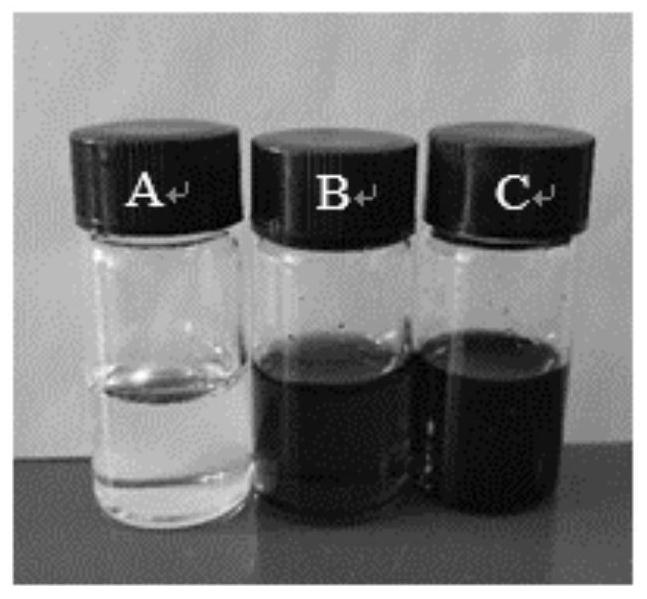

[0054] Step 1, preparation of choline chloride / ethylene glycol deep eutectic solvent: use choline chloride and ethylene glycol as raw materials, mix them in a beaker at a molar ratio of 1:2, and stir at 40°C for 12 hours until Form a homogeneous colorless transparent liquid, such as figure 2 Solution A shown in;

[0055] Step 2, preparation of electrolyte solution: 0.2M (2.38g) of nickel chloride hexahydrate (analytical pure) and 0.1M (1.19g) of cobalt chloride hexahydrate (analytical pure) were added to the 50mL prepared in step 1 In the deep eutectic solvent, stir at 40°C for 2 hours to obtain a uniform dark green transparent liquid, such as figure 2 Solution B shown in ; add 0.3g...

Embodiment 2

[0063] In this example, a method for preparing single-atom platinum composite electrocatalytic hydrogen evolution materials by controllable dissolution of platinum electrodes is mainly introduced. The process flow is as follows: figure 1 As shown, the operation steps are roughly the same as in Embodiment 1:

[0064] Step 1, with embodiment one;

[0065] Step 2, preparation of electrolyte solution: 0.2M (2.38g) of nickel chloride hexahydrate (analytical pure) and 0.1M (1.19g) of cobalt chloride hexahydrate (analytical pure) were added to the 50mL prepared in step 1 In the deep eutectic solvent, stir at 40°C for 2 hours to obtain a uniform dark green transparent liquid, such as figure 2 Solution B shown in ; Add 0.2g of single-layer graphene particles (GO) to the prepared solution, after ultrasonication for 1h, stir at 40°C for 2h, and finally obtain a suspended black liquid such as figure 2 Electrolyte C shown in;

[0066] Step 3, with embodiment one;

[0067] Step 4. Syn...

Embodiment 3

[0073] In this example, a method for preparing single-atom platinum composite electrocatalytic hydrogen evolution materials by controllable dissolution of platinum electrodes is mainly introduced. The process flow is as follows: figure 1 As shown, the operation steps are roughly the same as in Embodiment 1:

[0074] Step 1, with embodiment one;

[0075] Step 2, preparation of electrolyte solution: 0.2M (2.38g) of nickel chloride hexahydrate (analytical pure) and 0.1M (1.19g) of cobalt chloride hexahydrate (analytical pure) were added to the 50mL prepared in step 1 In the deep eutectic solvent, stir at 40°C for 2 hours to obtain a uniform dark green transparent liquid, such as figure 2 Solution B shown in ; Add 0.4g of single-layer graphene particles (GO) to the prepared solution, after ultrasonication for 1h, stir at 40°C for 2h, and finally obtain a suspended black liquid such as figure 2 Electrolyte C shown in;

[0076] Step 3, with embodiment one;

[0077] Step 4, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com