Solid aluminum electrolytic capacitor based on PEDOT: SNC and preparation method thereof

An aluminum electrolytic capacitor, solid-state technology, applied in the direction of solid electrolytic capacitors, electrolytic capacitor manufacturing, electrolytic capacitors, etc., can solve the problems of reduced amount of polymer conductive polymer, troublesome removal of impurities, and many holes, etc., to achieve good redispersibility, The effect of controlled conductivity and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

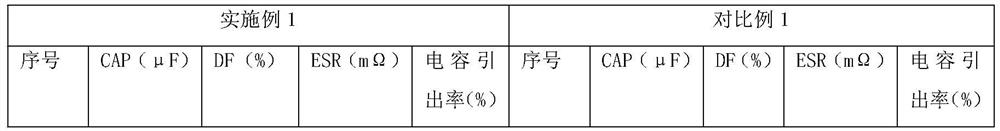

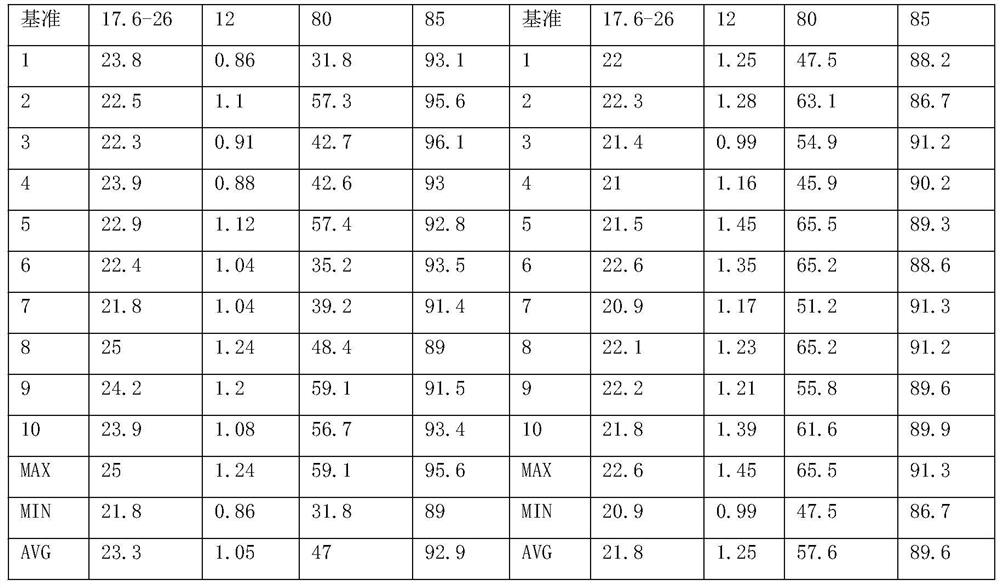

Examples

Embodiment 1

[0033] This embodiment provides a solid aluminum electrolytic capacitor based on PEDOT:SNC, which includes a core package wound by anode foil, electrolytic paper and cathode foil, and a polymer conductive polymer film is formed between the anode foil and the cathode foil. The conductive polymer film includes PEDOT:SNC film; the weight ratio of PEDOT:SNC is 1:1.

[0034] In the present embodiment, the preparation of sulfated nanocellulose; comprises the following steps, 1. sulfamic acid is added in DMF, mixes evenly, adds cellulose, then carries out heating reaction; The cellulose adopts pine wood pulp, and the temperature of heating reaction is 80 -120°C, the time is 2-4 hours.

[0035] ② Obtain the reaction solution, filter and dialysis to remove impurities, take the filter residue and add it to the dispersion;

[0036] ③Use a disperser to disperse uniformly by centrifugation to obtain the sulfated nanocellulose aqueous dispersion; the rotational speed of the disperser is se...

Embodiment 2

[0051] The difference between this example and Example 1 is that in Example 1, the core contains PEDOT:SNC dispersion solution, while in this example, the core package is first impregnated with sulfated nanocellulose water containing EDOT monomer. dispersion, and then impregnated with the mixture of oxidant and ammonium persulfate; the polymerization reaction is carried out on the core bag, which will cause certain damage to the anodic oxide film due to the polymerization reaction on the core bag, but this method can More impregnated polymerized monomers, that is, more EDOT can be impregnated in the core package. At the same time, this situation is more conducive to the cost control of manufacturers of solid aluminum electrolytic capacitors, because the cost price of PEDOT: SNC is relatively high . The preparation method of the solid aluminum electrolytic capacitor of the present embodiment comprises the following steps:

[0052] 1) preparing sulfated nanocellulose;

[0053]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com