Catalyst for denitration of low-temperature and low-oxygen flue gas as well as preparation method and application of catalyst

A catalyst, low-temperature technology, applied in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as low efficiency, concentrated precipitation of urea recrystallization, and failure to achieve loading effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

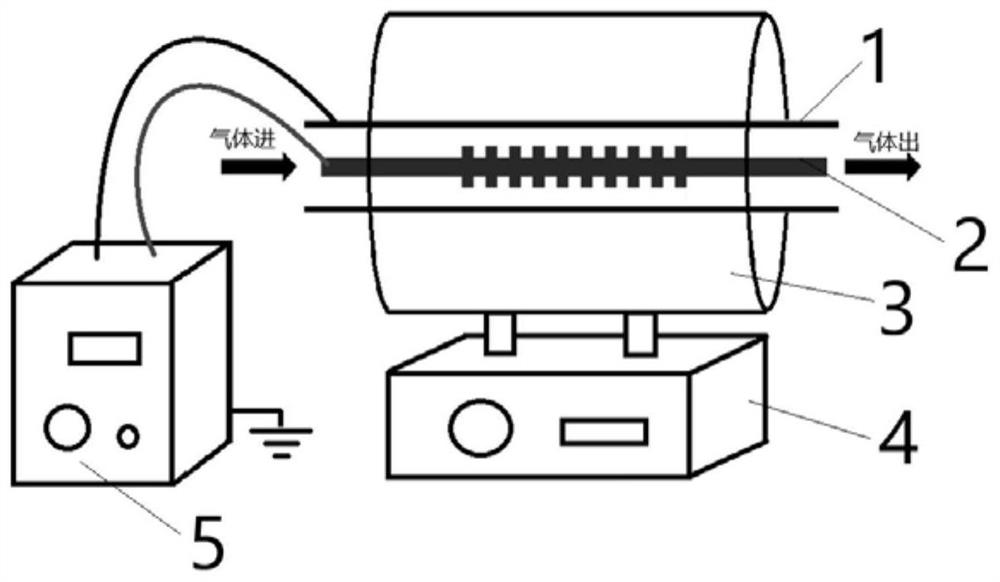

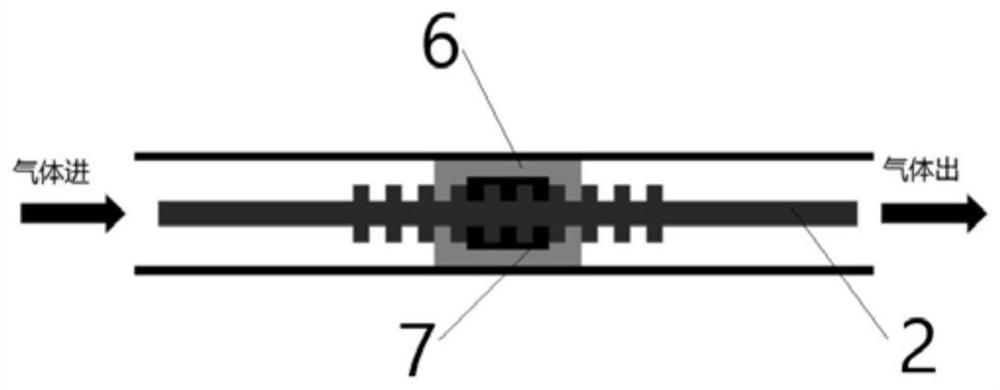

Method used

Image

Examples

preparation example Construction

[0031] A preparation method of a urea-doped bimetallic catalyst, comprising the following steps:

[0032] Step 1, add manganese nitrate aqueous solution, ferric nitrate aqueous solution and deionized water dropwise to the SBA-15 molecular sieve carrier successively, stir to make them fully mixed, and obtain a mixed solution; wherein, the mass concentration of the manganese nitrate aqueous solution is 5 ~ 50g / L ; The mass concentration of ferric nitrate aqueous solution is 1~20g / L;

[0033] It is optimal when the concentration of manganese nitrate aqueous solution is 20g / L, and optimal when the concentration of ferric nitrate aqueous solution is 10g / L.

[0034] In step 2, the mixed solution obtained in step 1 is left to age until the active component is fully adsorbed on the surface of the carrier to obtain a system, and then the obtained system is dried in an oven to obtain a powder.

[0035] Step 3, roasting the powder obtained in step 2 to obtain a MnFe / SBA-15 system; where...

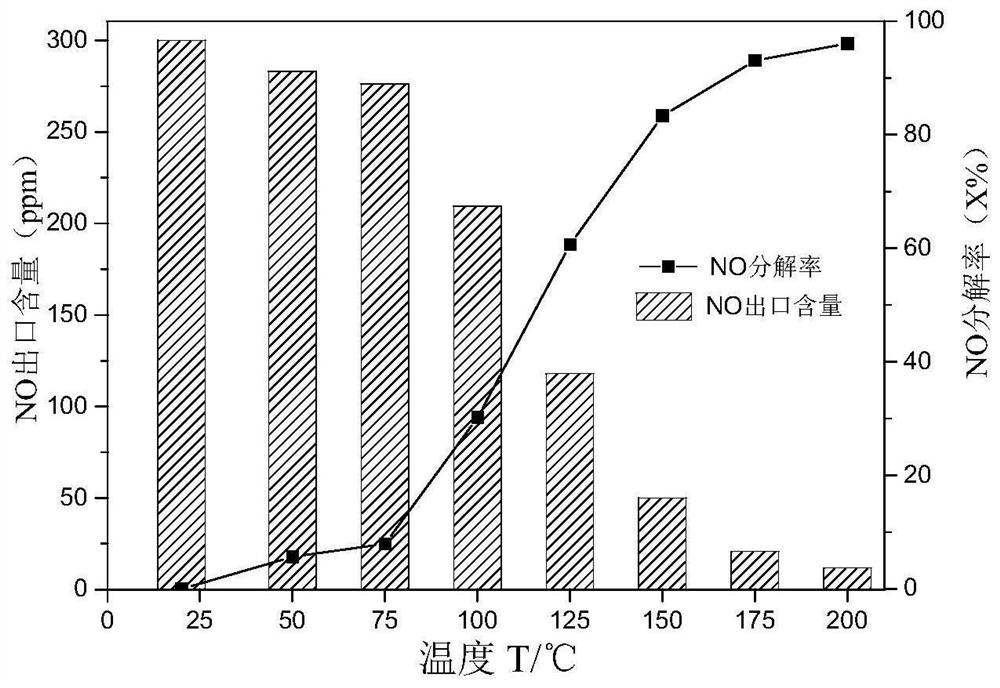

Embodiment 1

[0045] A preparation method of a urea-doped bimetallic catalyst, comprising the following steps:

[0046] Step 1, take by weighing 1g SBA-15 molecular sieve carrier, 16.25mL mass concentration be the manganese nitrate solution of 20g / L, 2.42mL mass concentration be the ferric nitrate solution of 10g / L and 50mL water;

[0047] Step 2, add manganese nitrate aqueous solution, ferric nitrate aqueous solution and water to the weighed SBA-15 molecular sieve carrier successively, stir fully at 40°C for 1h, then let it stand for 24h; then place it in a vacuum oven at 60°C Drying is carried out to obtain a powder.

[0048] Step 3, calcining the powder obtained in step 2 in a muffle furnace at 500° C. for 4 hours to obtain a MnFe / SBA-15 catalyst.

[0049] Step 4, weigh 1g of MnFe / SBA-15 catalyst, slowly add 15mL of urea (urea) solution with a concentration of 10g / L dropwise, stir well and let stand for 6h; then put it in an oven at 50°C to dry to obtain urea- MnFe / SBA-15 catalyst. Th...

Embodiment 2

[0052] A preparation method of a urea-doped bimetallic catalyst, comprising the following steps:

[0053] Step 1, take by weighing 1g SBA-15 molecular sieve carrier, 16.25mL mass concentration be the manganese nitrate solution of 20g / L, 2.42mL mass concentration be the ferric nitrate solution of 10g / L and 50mL water;

[0054] Step 2, add manganese nitrate aqueous solution, ferric nitrate aqueous solution and water to the weighed SBA-15 molecular sieve carrier successively, stir fully at 40°C for 1h, then let it stand for 24h; then place it in a vacuum oven at 60°C Drying is carried out to obtain a powder.

[0055] Step 3, calcining the powder obtained in step 2 in a muffle furnace at 500° C. for 4 hours to obtain a MnFe / SBA-15 catalyst.

[0056] Step 4, weigh 1g of MnFe / SBA-15 catalyst, slowly add 15mL of urea (urea) solution with a concentration of 10g / L dropwise, stir well and let stand for 6h; then put it in an oven at 50°C to dry to obtain urea- MnFe / SBA-15 catalyst. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com