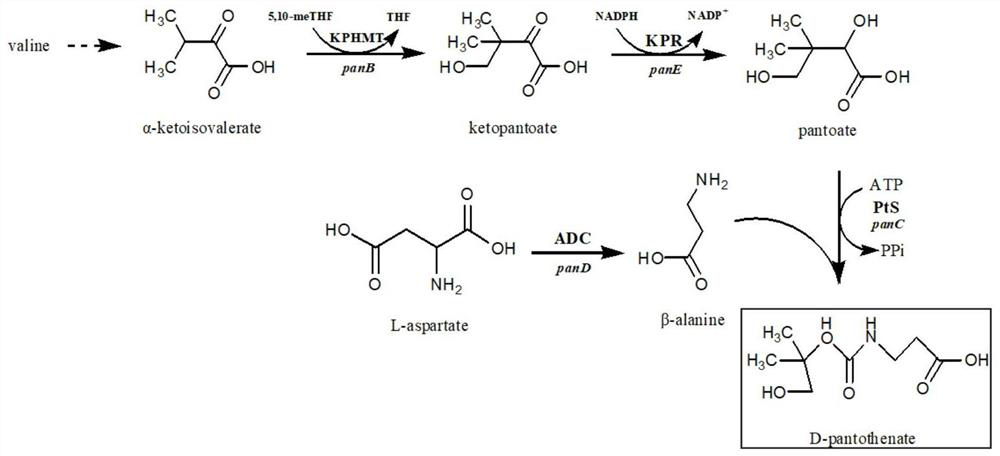

High-yield D-pantothenic acid genetically engineered bacterium and construction and application thereof

A technology of genetically engineered bacteria and pantothenic acid, which can be used in genetic engineering, application, plant genetic improvement, etc., and can solve the problems that cannot be produced with pantothenic acid derivatives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Preparation of E.coli DH5α Competent

[0039] Streak the E.coli DH5α stored at -80°C on an LB plate without anti-antibody, culture at 37°C for 12 hours, and grow a single colony. Pick a single colony and inoculate it in 10 mL of LB liquid medium, and then shake it at 37°C and 150 rpm for 12 hours. Transfer to 50mL LB liquid medium with 1% inoculum amount, then shake culture at 37°C and 150rpm for about 2h, when the culture OD 600 When it is close to 0.6-0.8, ice bath for more than 30min to stop the growth. Afterwards, the cells were collected by centrifugation at 5000 rpm for 5 min at 4°C, and the supernatant was discarded. Then add 20 mL of pre-cooled 0.1M CaCl 2 The solution was resuspended and placed in an ice bath for 30 min. Repeat centrifugation and addition of 0.1M CaCl 2 Solution resuspension operation. Collect the cells by centrifugation at 5000 rpm for 10 min at 4°C and discard the supernatant. Add 1 mL (per 50 mL of medium) of 0.1 M CaCl con...

Embodiment 2

[0040] Embodiment 2: Preparation of bacterial strain DPA-11 competent

[0041] The pTrc99A plasmid was purchased from Addgene Company, the product number is VT1294. The strain DPA-11 and the strain DPA-11-pTrc99A-panBpanC were constructed and preserved in the laboratory of the School of Bioengineering, Zhejiang University of Technology.

[0042] Strain DPA-11 Construction:

[0043] (1) Applying CRISPR-Cas9 gene editing technology to replace the promoters of panC, panB, panE and ilvC genes in the genome of E. coli W3110 with the trc promoter to obtain strain E. coli W3110 Trc-panCpanEpanBilvC;

[0044] (2) Applying CRISPR-Cas9 gene editing technology to repair the ilvG gene in the genome of the strain E.coli W3110 Trc-panCpanEpanBilvC to obtain the strain E.coli W3110 Trc-panCpanEpanBilvC / ilvG*;

[0045] (3) The avtA gene in the strain E.coli W3110 Trc-panCpanEpanBilvC / ilvG* was knocked out using CRISPR-Cas9 gene editing technology to obtain the strain E.coli W3110 Trc-panCpanE...

Embodiment 3

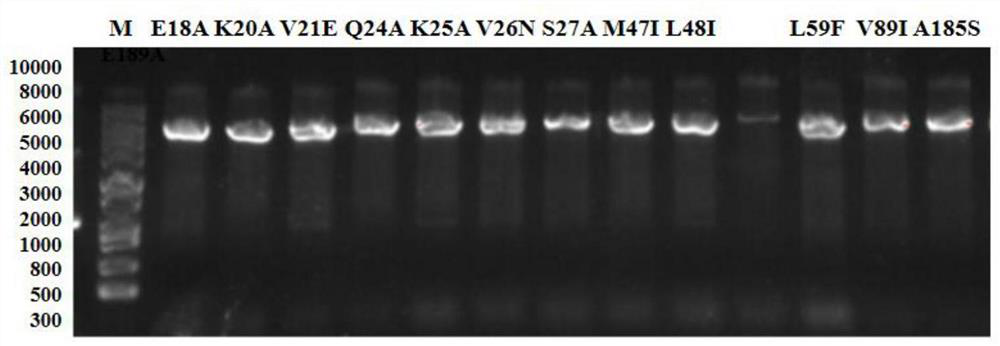

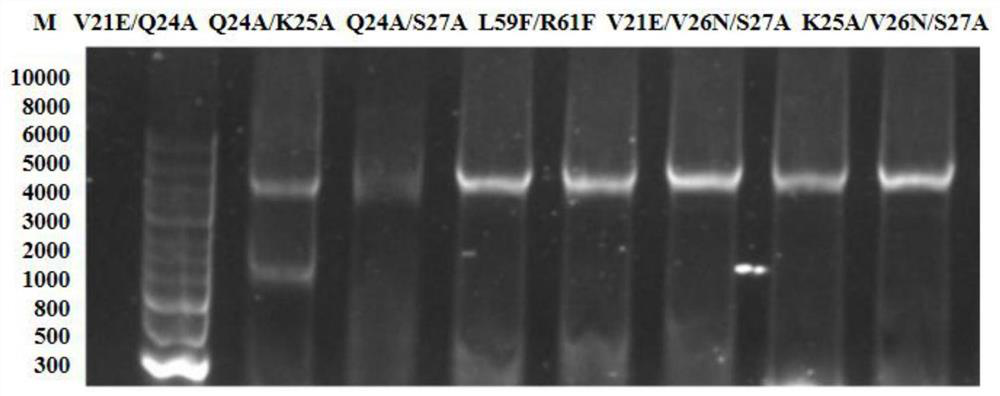

[0057] Example 3: Construction of a single mutation site library

[0058] The 3D model of panB derived from Corynebacterium glutamicum was constructed by Swiss-Model, and the model of KPHMT (panB) and the substrate small molecules α-ketoisovaleric acid and 5,10-methylene were connected using AutoDock molecular docking software Based on tetrahydrofolate for molecular docking, the key sites on the panB gene were selected for mutation. Design primers to construct single mutation site genetically engineered bacteria.

[0059] Primers were designed as follows:

[0060] E18A

[0061] Upstream primer 1: ACCCGTCATTTCCGCGCTGCTAAAGTAAACGGC

[0062] Downstream primer 2: AGCGCGGAAATGACGGGTGCGGATTTTCTTTGC

[0063] K20A

[0064] Upstream primer 3: CATTTCCGCGAAGCTGCTGTAAACGGCCAGAAA

[0065] Downstream primer 4: AGCAGCTTCGCGGAAATGACGGGTGCGGATTTT

[0066] V21E

[0067] Upstream primer 5: TTCCGCGAAGCTAAAGAGAACGGCCAGAAAGTT

[0068] Downstream primer 6: CTCTTTAGCTTCGCGGAAATGACGGGTGCGGAT ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com