Active lignin as well as preparation method and application thereof

A lignin and active technology, applied in the direction of organic active ingredients, pharmaceutical formulas, medical preparations containing active ingredients, etc., can solve the problems of not meeting the use requirements, cumbersome purification process, affecting performance, etc., and achieve good biocompatibility and antioxidant properties, enriching the content of phenolic hydroxyl functional groups, and promoting the repair of cartilage defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

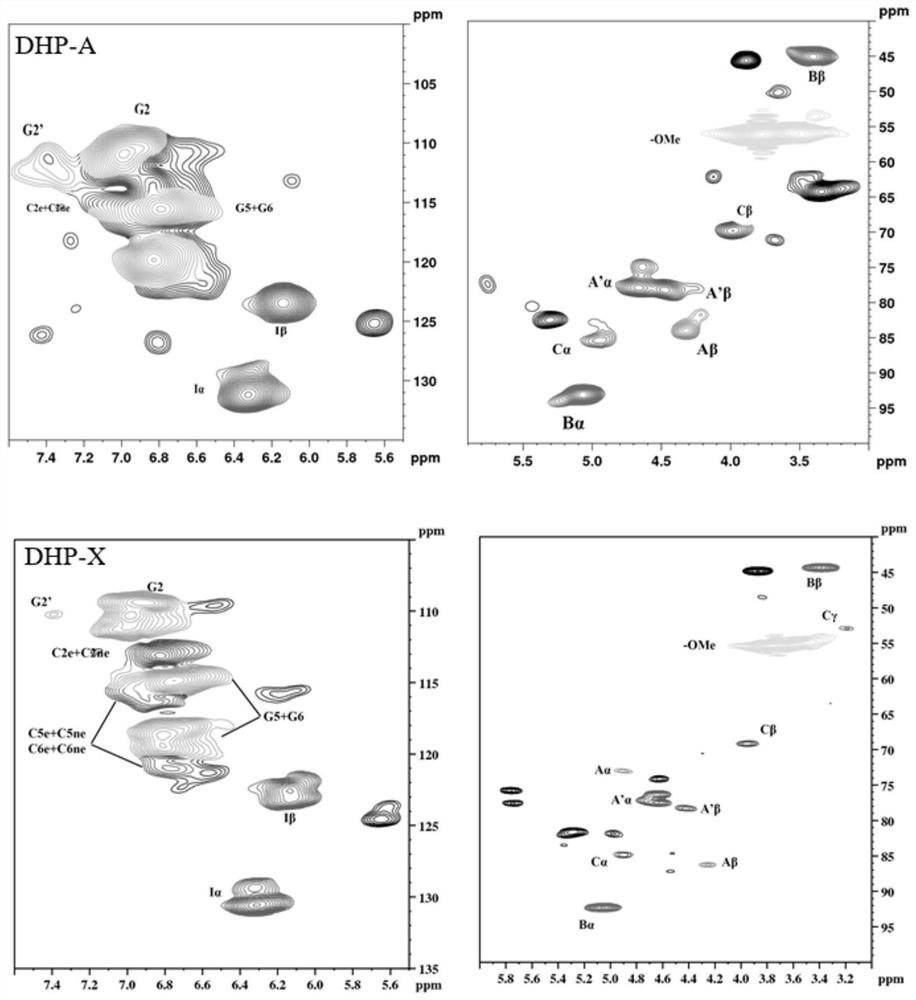

[0025] Synthesis of active lignin: Prepare pH 5 acetic acid / sodium acetate buffer and mix it with ethanol in equal volume. Then take by weighing 5g arabinose and 5g isoeugenol (test 1), 5g xylose and 5g isoeugenol (test 2) respectively, respectively mix uniformly, all add the acetic acid / sodium acetate of configuration, ethanol buffer under aseptic condition Mix liquid 70mL, dissolve fully. Add 1mL of laccase with an activity of 1000IU / mL and mix well, then place the system in a water bath at 30°C for 24 hours, then add 1mL of laccase, and add 30mL of absolute ethanol at the same time. After aseptic reaction for 5 days, wash with distilled water, centrifuge, keep the precipitated part, which is the crude product, and freeze-dry. The freeze-dried crude product was added to 100 mL of dichloroethane / ethanol mixed solution with a volume ratio of 2:1. After reacting for 6 hours, the liquid part was collected by centrifugation, and the active lignin DHP was obtained by rotary evapo...

Embodiment 2

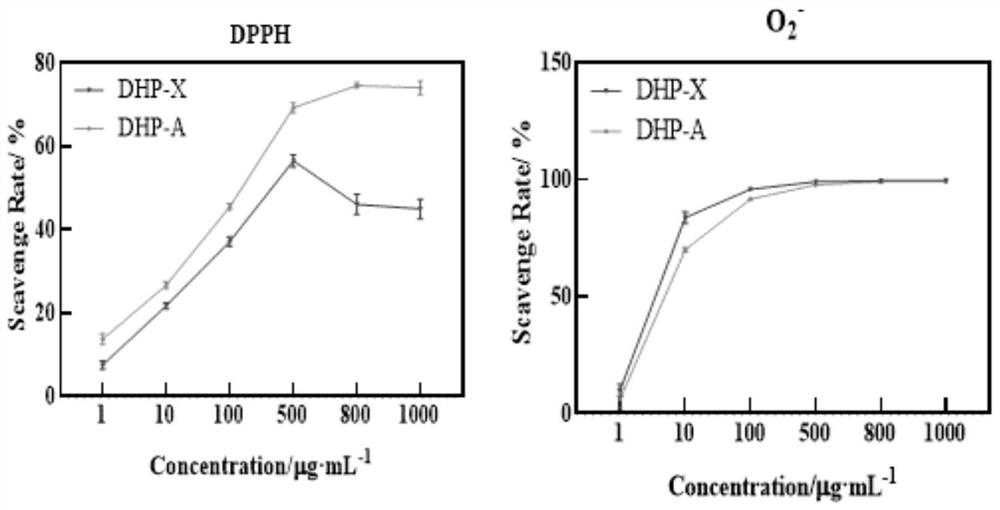

[0032] Cytotoxicity and antioxidant performance of embodiment 2 active lignin are measured

[0033] (1) Cytotoxicity assay

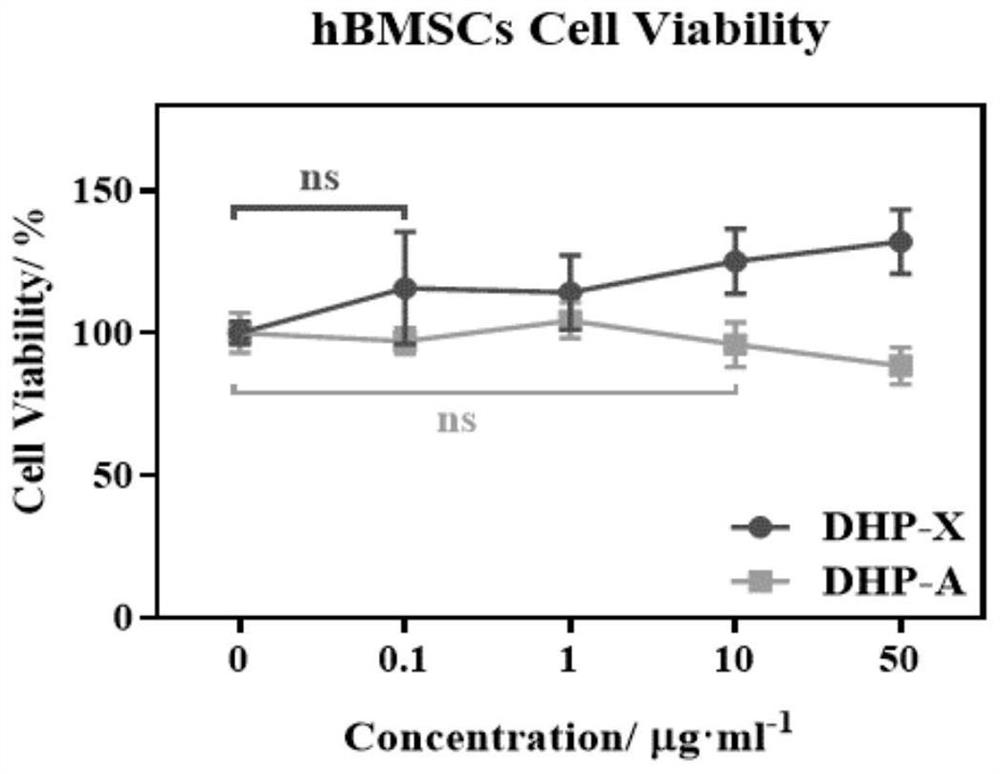

[0034] The toxicity test of active lignin to human bone marrow mesenchymal stem cells was determined by co-cultivating cells with different concentrations (0.1ug / mL, 1ug / mL, 10ug / mL, 50ug / mL) of DHP-X and DHP-A for 24h , Cell viability was determined by cck-8.

[0035] figure 2 is the cell viability data. At a low concentration of DHP (0.1-10 μg / mL), there is basically no toxicity to BMSCs in 24 hours, and there is no cell death phenomenon. When the DHP concentration was 1 μg / mL, DHP-X had no obvious promoting effect on cell proliferation, and DHP-A showed a certain effect on promoting osteoblast proliferation, which may be due to the higher hydroxyl content of DHP-A, thus showing a certain physiological activity. The effect of 50μg / mL DHP-X on cell proliferation is more significant. But when the concentration of DHP-A was 50μg / mL, it had no signifi...

Embodiment 3

[0044] Example 3 Active lignin promotes cartilage differentiation experiment

[0045] Firstly, the chondrogenic differentiation of BMSCs was induced by a commercial kit (adult bone marrow mesenchymal stem cell chondrogenic differentiation induction medium, Saiye Biotech, HUXMA-90041). During the induction process, 1ug / mL DHP-A and DHP-X were added for co-cultivation. After 18 days of continuous induction, the cartilage balls were taken out and observed under a zoom stereomicroscope and photographed. Frozen sections were immunohistochemically stained with Alcian blue and type II collagen. Gross observation and staining of cartilage balls Figure 5 shown.

[0046] Depend on Figure 5 It can be concluded that the chondrogenic differentiation of adult bone marrow stem cells was successfully induced. The size analysis of the formed cartilage balls showed that the size of the cartilage balls induced by the control group was similar to that induced by DHP-A, and the size of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap