A kind of oil-water separation membrane based on oxime urethane bond, preparation method and application thereof

A technology of oil-water separation membrane and oxime carbamate, which is applied in the direction of separation method, immiscible liquid separation, liquid separation, etc., can solve the problems of high energy consumption, uncontrollable fiber structure, poor durability, etc., and achieve simple operation and high fiber structure adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

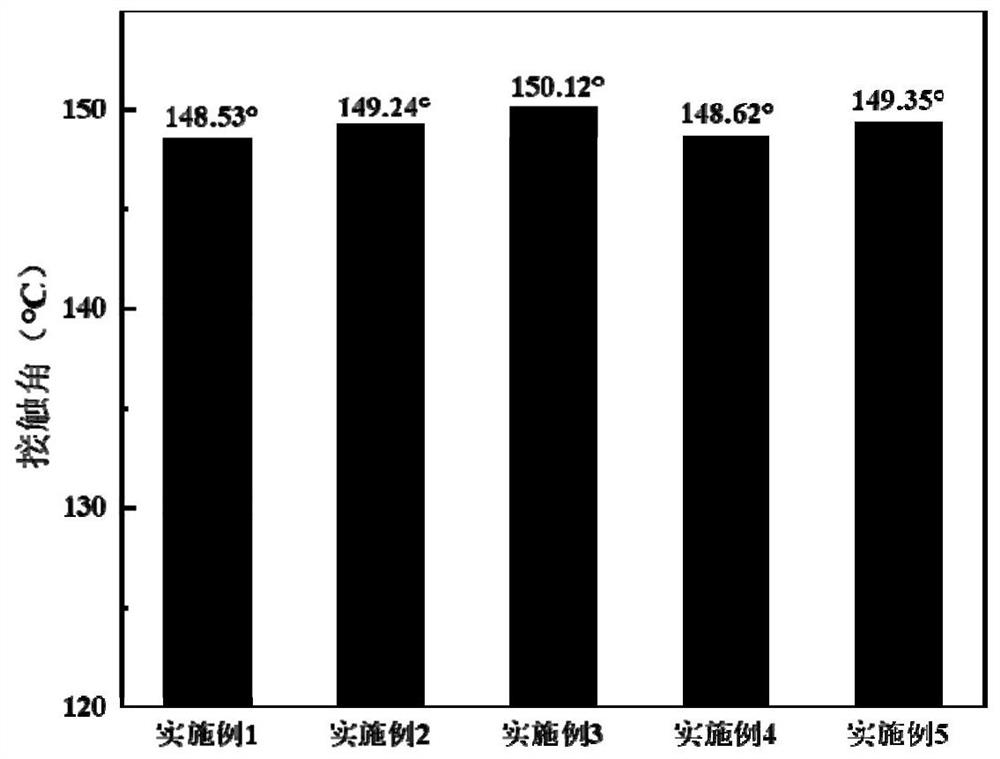

Embodiment 1

[0039] (1) After reacting diacetyl oxime and diphenylmethane diisocyanate with a molar ratio of 1:1 in dichloromethane at 30° C. for 3 hours, the solvent was removed by a rotary evaporator to obtain an oxime-containing urethane bond of compound 1.

[0040] Oximes containing multifunctional groups can also be selected from: butanedione oxime, benzophenone oxime, dichloroglyoxime, ceftizoxime sodium, benzamide oxime, bis(2-pyridine) ketone oxime, 2-pyridyl oxime Amidoxime, 4-methyl-2-pentanone oxime, tetrabutanone oximosilane, 2,4-pentanedione dioxime, phenyl-2-pyridyl ketoxime;

[0041] Compounds containing isocyanate groups can be selected from: p-phenylene diisocyanate, isophorone diisocyanate, dicyclohexylmethane diisocyanate, hexamethylene diisocyanate, diphenylmethane diisocyanate, toluene diisocyanate or 1,3-benzene diisocyanate;

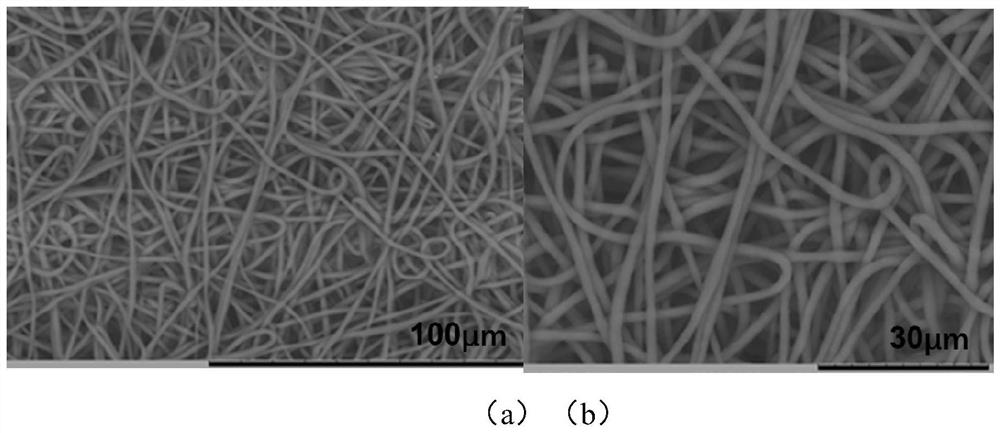

[0042] (2) Mix 1.00g of the compound containing an oxime urethane bond with 10.00mL of N,N-dimethylformamide at room temperature, then add 1...

Embodiment 2

[0049] The compound 1 containing an oxime urethane bond obtained in Example 1 and 10.00 mL of N,N-dimethylformamide were thoroughly mixed at room temperature, and then 0.8 g of polyvinylidene fluoride was added, mixed well, and allowed to stand for 30 min The electrospinning stock solution 2 can be obtained in the above manner.

[0050] The electrospinning stock solution 2 is then electrospun at a temperature of 25° C. and a humidity of 45%, and the spun nanofiber membrane is placed in a vacuum drying oven to evaporate the solvent to obtain an oxime urethane bond-based product. Oil-water separation membrane 2. Other steps are the same as in Example 1.

Embodiment 3

[0052] The compound 1 containing an oxime urethane bond obtained in Example 1 and 10.00 mL of N,N-dimethylformamide were fully mixed at room temperature, and then 0.6 g of polyvinylidene fluoride was added, mixed well, and allowed to stand for 30 min In the above, the electrospinning dope 3 can be obtained.

[0053] The electrospinning stock solution 3 is then electrospun in an environment with a temperature of 15° C. and a humidity of 43%, and the spun nanofiber membrane is placed in a vacuum drying oven to evaporate the solvent to obtain an oxime-based urethane bond. The oil-water separation membrane 3. Other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com