Preparation method and application of zinc ion battery metal zinc negative electrode dynamic interface coating

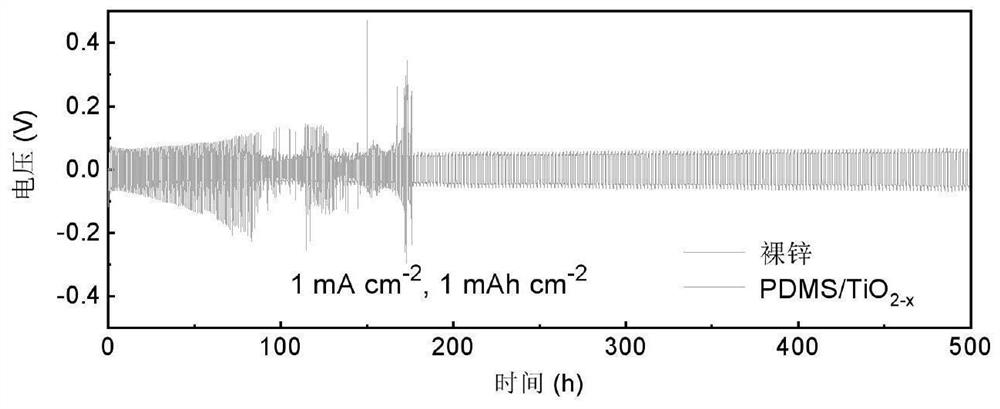

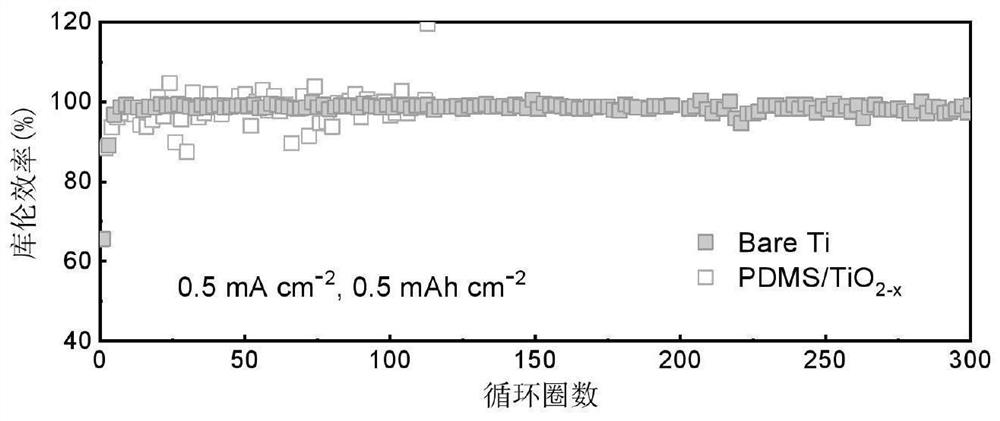

A zinc-ion battery and interface coating technology, which is applied in electrode collector coating, electrode manufacturing, battery electrodes, etc., can solve problems such as low Coulombic efficiency, cycle life attenuation, negative electrode interface volume expansion, etc., and achieve simple and easy raw materials Obtain, improve cycle life, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] DETAILED DESCRIPTION OF THE INVENTION First: The present embodiment is a method of preparing a zinc ion battery metal zinc negative electrode dynamic interface coating, the method comprising the steps of:

[0027] Step 1, boric acid is added to dimethyl silicone oil, and mix well at high speed, then adding ferric chloride, catalytic crosslinking under high temperature conditions;

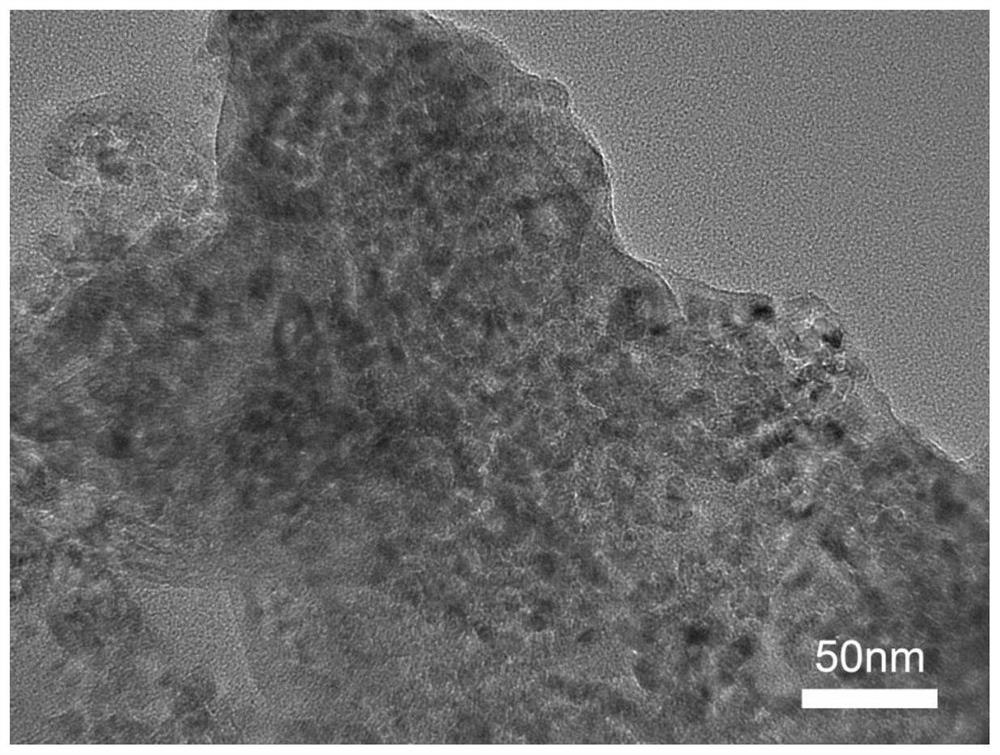

[0028] Step 2, Titanium Dioxide TiO 2 At a temperature of 400 ~ 450 ° C, the argon hydrogen gas volume ratio of 95: 5 is heat-treated to obtain an oxygen-containing defect TiO 2-x ;

[0029] Step three, dissolve the prepared PDMS with volatile ether organic solvent, then add organic salt Zn (TFSI) 2 ;

[0030] Step four, the preparative oxygenate defect TIO 2-x Add to step three solutions, oxygen-containing defect TiO 2-x With the mass ratio of steps of steps of 2% to 15%, high-speed stirring is mixed;

[0031] Step 5. Wash the surface of the zinc foil with sandpaper, then cleaning it with deioni...

specific Embodiment approach 2

[0035] DETAILED DESCRIPTION OF THE INVENTION 2: DETAILED DESCRIPTION OF THE INVENTION A method for preparing a zinc ion battery metal zinc negative electrode dynamic interface coating, in step one, the high temperature condition is 180 ° C ~ 220 ° C, the temperature is too low, and it will not The reaction is too high for the preparation.

specific Embodiment approach 3

[0036] DETAILED DESCRIPTION OF THE INVENTION 3: DETAILED DESCRIPTION OF THE INVENTION A method of preparing a zinc ion battery metal zinc negative electrode dynamic interface coating, wherein the boric acid, dimethyl silicone oil and iron chloride is 0.1 ~ 1g: 1 ml: 0.01g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com