Device and method for DMSO concentration process

A process and technology of concentration tower, which is applied in the device field of DMSO concentration process, can solve the problems of high energy consumption and high operating cost, and achieve the effects of reducing operating cost, safe and reliable operation, and reducing rectification temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

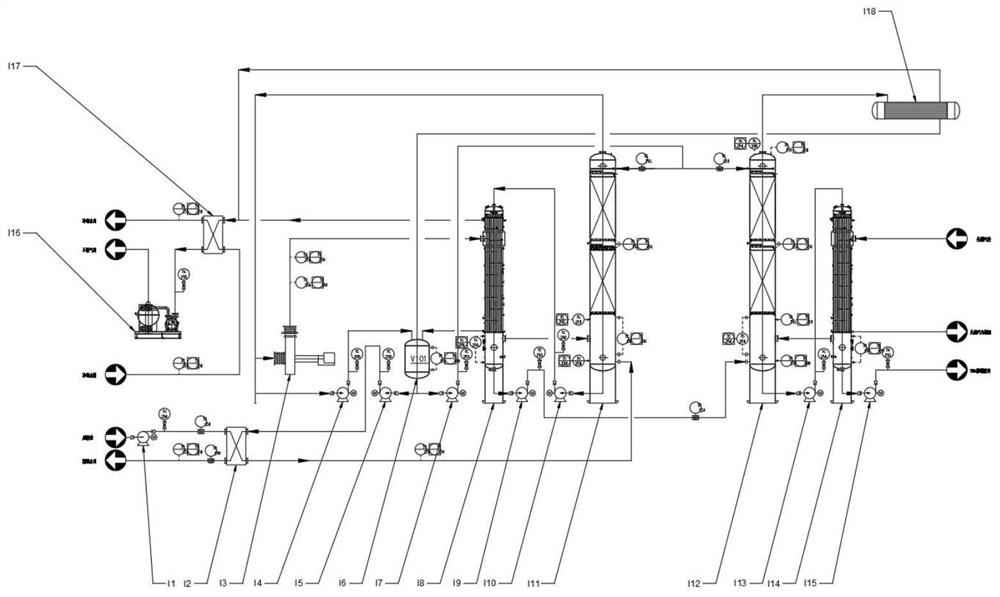

[0034] refer to figure 1, a device for the DMSO concentration process, including a stock solution buffer tank through which DMSO passes sequentially, a stock solution feed pump, a distilled water preheater, the first section of rectification and concentration tower, the first section of circulating pump, and the first section of falling film evaporator , material transfer pump, second-stage rectification and concentration tower, first-stage circulating pump, first-stage falling film evaporator, discharge pump, the heat exchange medium inlet of the distilled water preheater passes through the distilled water pump, the distilled water tank and the first The shell-side outlet of the falling film evaporator is connected, and the distilled water tank is provided with a condensate inlet connected to the inlet pipe of the compressor through the liquid accumulation pump, and is also provided with an interface connected to the drain of the top condenser; the first falling film evaporato...

Embodiment 2

[0036] The DMSO enrichment process method based on said device may further comprise the steps:

[0037] S1 Feed: The material to be processed is temporarily stored in the raw liquid buffer tank. After coming out of the tank, the raw liquid feed pump is pumped into the distilled water preheater for heat exchange and then enters the bottom of the first stage of rectification and concentration tower. The distilled water is preheated The heating medium of the heater is discharged from the distilled water tank, transported to the distilled water preheater by the distilled water pump, exchanges heat with the material and then is discharged out of the device after cooling.

[0038] S2 evaporation: After the material is discharged from the bottom of the first section of rectification and concentration tower, it is transported to the top of the first section of falling film evaporator by the first section of circulating pump, and the material at the top passes through the liquid distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com