Preparation method of ferrous sulfate tetrahydrate

A technology of ferrous sulfate and crystal transformation, which is applied in the direction of ferric sulfate, can solve the problem of ferrous sulfate losing its reducing ability, and achieve the effect of improving utilization value, good economic benefits, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

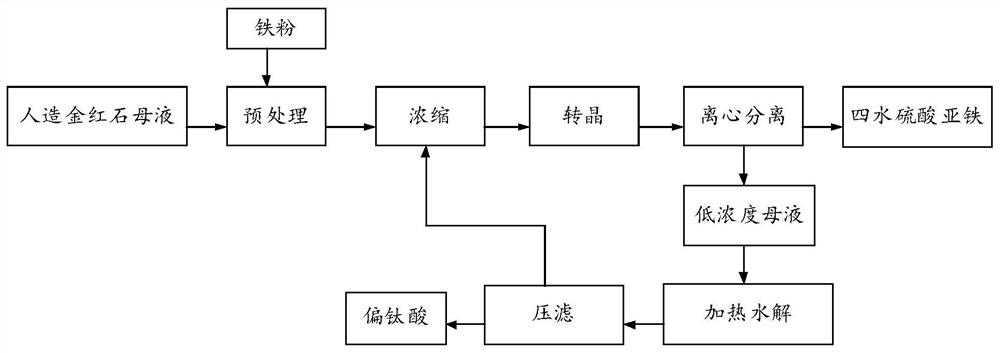

[0037] According to one aspect of the present invention, the present invention relates to a kind of preparation method of ferrous sulfate tetrahydrate, comprises the following steps:

[0038] The artificial rutile mother liquor is subjected to concentration treatment and crystal transformation treatment, and then solid-liquid separation is carried out to obtain ferrous sulfate tetrahydrate and a liquid phase system containing ferrous sulfate;

[0039] The temperature of the concentration treatment is 60-80° C.; the mass percentage of iron in the mixed solution after the concentration treatment is 14%-18%;

[0040] The temperature of the crystal transformation treatment is 60-80°C.

[0041] In order to avoid the waste of resources caused by direct crystallization and neutralization, the high processing cost, and the situation of secondary pollution, the present invention is based on the green vitriol, yellow ferrous and the mixture of green vitriol and yellow ferrous However, ...

Embodiment 1

[0082] A preparation method for ferrous sulfate tetrahydrate, comprising the following steps:

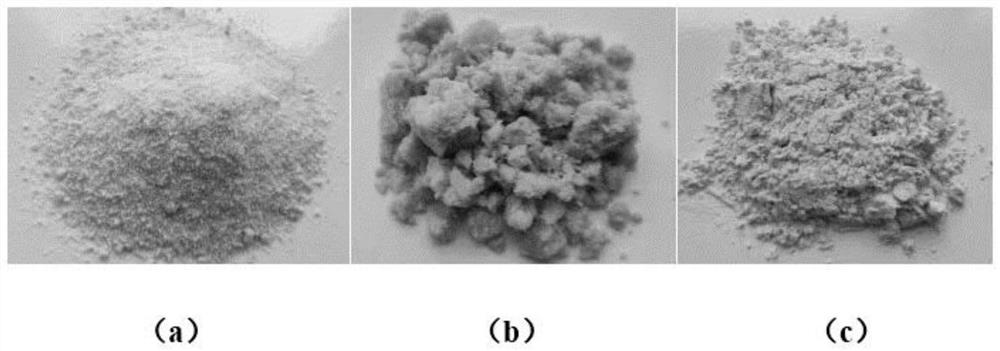

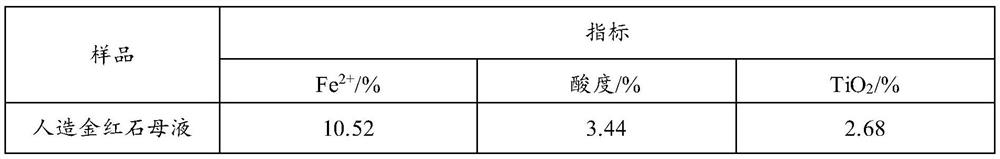

[0083] At 25°C, add iron powder to the artificial rutile mother liquor, react until the sulfuric acid content in the artificial rutile mother liquor drops to 0.1%, settle and filter to obtain a saturated solution of ferrous sulfate with low acidity; Concentrate until the iron ion content in the solution is 14%, then carry out crystal transformation, keep the crystal transformation temperature at 60°C, stir at 150rpm, centrifuge after 3 hours of crystal transformation to obtain iron content of 24.65% ferrous sulfate tetrahydrate, other indicators and The yield of one-time crystal transformation is shown in Table 2 below; the liquid phase system after centrifugation is heated and hydrolyzed to obtain solid phase metatitanic acid. The heating temperature is 90°C, and then pressure filtration is performed. Return for concentrated processing.

Embodiment 2

[0085] A preparation method for ferrous sulfate tetrahydrate, comprising the following steps:

[0086] At 50°C, add reduced ilmenite to the artificial rutile mother liquor, react until the sulfuric acid content in the artificial rutile mother liquor drops to 0.08%, then settle and filter to obtain a low-acidity ferrous sulfate saturated solution; Concentrate the iron solution at 80°C until the content of iron ions in the solution is 18%, then conduct crystal transformation, keep the crystal transformation temperature at 70°C, stir at 200rpm, centrifuge after 4 hours to obtain iron content of 25.74% tetrahydrate Ferrous sulfate, other indicators and the yield of one-time crystal transformation are shown in Table 2 below; the liquid phase system after centrifugation is heated and hydrolyzed to obtain solid phase metatitanic acid. The liquid phase obtained after filtration is returned for concentration treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com