Preparation method and shape fixing method of ceramic slurry

A technology of ceramic slurry and ceramic powder, applied in the field of ceramics, can solve the problems of unfavorable ceramic electronic device manufacturing, complex photo-curing process engineering, prone to cracks or deformation, etc., to accelerate the photo-curing molding process and shorten the surface solidification time. , the effect of enhancing the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

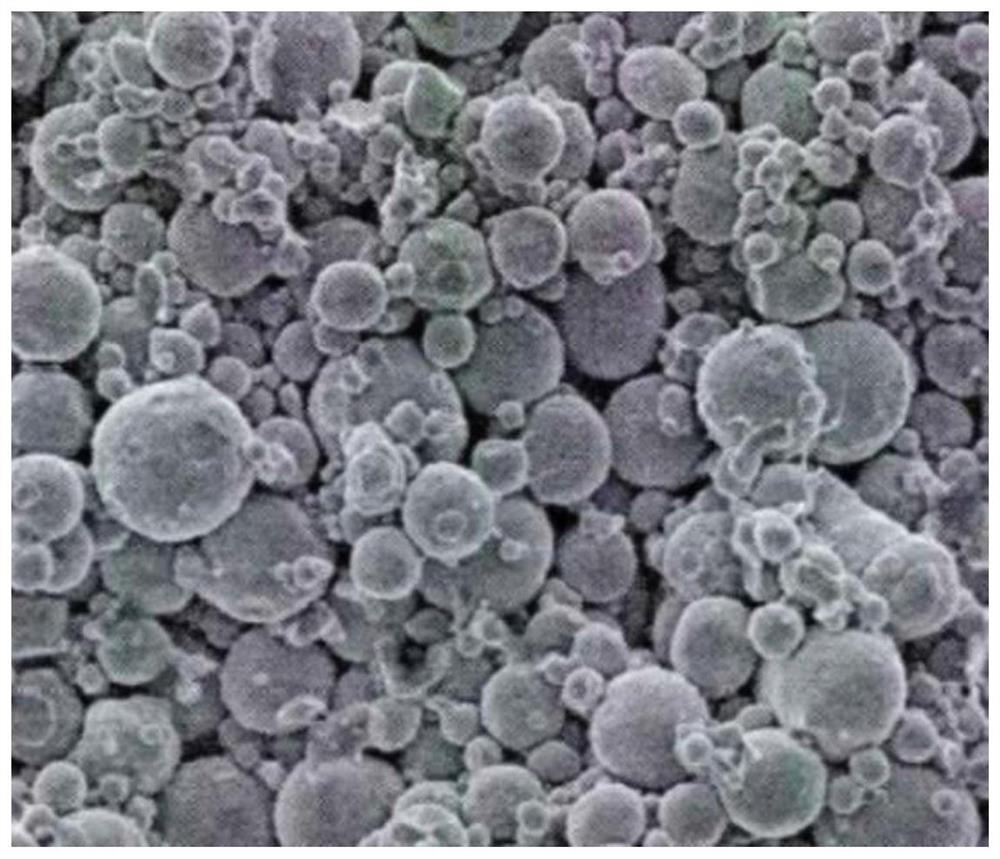

Image

Examples

Embodiment 1

[0026] Step 1: Mix and ball mill 3vol% oxides, the oxides include oxide A and oxide B, add 18vol% photosensitive resin and 2vol% additives, stir and mix, add 77vol% ceramic powder, stir and homogenize, and obtain a solid content of 82% ceramic slurry.

[0027]Step 2: Set the light-curing wavelength to 400nm, and print the ceramic slurry layer by layer through a DLP-type light-curing 3D printer. Dry in an oven at 60°C for 2 hours, transfer to a debinding furnace with an inert atmosphere, and heat up to 500°C at a heating rate of 2°C / min under the irradiation of an ultraviolet lamp with a wavelength of 400nm; Degrease for 1 hour; dry again, transfer to a vacuum or inert gas sintering furnace, and sinter at a controlled temperature to obtain a ceramic product.

[0028] In this scheme, oxide A is 10nm SiO 2 ;Oxide B is 20nm TiO 2 . Photosensitive resin urea-formaldehyde resin. Ceramic powder is 250nm Al 2 o 3 And alkali metal titanate mixture, under UVA conditions, the spec...

Embodiment 2

[0030] Step 1: Mix and ball mill 4vol% oxides, the oxides include oxide A and oxide B, add 45vol% photosensitive resin and 1vol% additives, stir and mix, add 50vol% ceramic powder, stir and homogenize, and obtain a solid content of 55% ceramic slurry.

[0031] Step 2: Set the light-curing wavelength to 400nm, and print the ceramic slurry layer by layer through an SLA-type light-curing 3D printer. Dry in an oven at 60°C for 2 hours; transfer to a debinding furnace with an inert atmosphere, and under the irradiation of a UV lamp with a wavelength of 400nm, the temperature rises at a rate of 2°C / min to 500°C; hour, degrease; dry again, transfer to vacuum or inert gas sintering furnace, temperature control sintering, to obtain ceramic products.

[0032] In this scheme, oxide A is 5nm Al 2 o 3 ;Oxide B is 15nm TiO 2 . The photosensitive resin is polyaldehyde resin. The ceramic powder is alkali metal titanate with a thickness of 100 nm, and the spectral light transmittance is ...

Embodiment 3

[0034] Step 1: Mix and ball mill 1vol% oxides, the oxides include oxide A and oxide B, add 10vol% photosensitive resin and 4vol% additives, stir and mix, add 85vol% ceramic powder, stir and homogenize, and obtain a solid content of 85% ceramic slurry.

[0035] Step 2: Set the light-curing wavelength to 300nm, and print the ceramic slurry layer by layer through a DLP-type light-curing 3D printer. Dry in an oven at ℃ for 1 hour, transfer to a debinding furnace with an inert atmosphere, use an oxalic acid catalyst under the irradiation of a UV lamp with a wavelength of 300nm, and set the temperature at 150℃ to degrease; dry again, and transfer to vacuum or inert gas In a sintering furnace, the temperature is controlled and sintered to obtain ceramic products.

[0036] In this scheme, oxide A is 20nm SiO 2 、Al 2 o 3 , ZrO 2 One or more of , CaO, MgO; oxide B is 40nm silicon dioxide surface-modified TiO 2 . The photosensitive resin is polyaldehyde resin. Ceramic powder is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com