Rock braised sauce as well as preparation method and application thereof

A technology for yaki sauce and raw materials, which is applied in the field of yaki sauce and its preparation, can solve the problems of easy-to-stick packaging bags, sticky bags, etc., and achieves the effects of reducing moisture, reducing water activity, and avoiding sticking bags.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

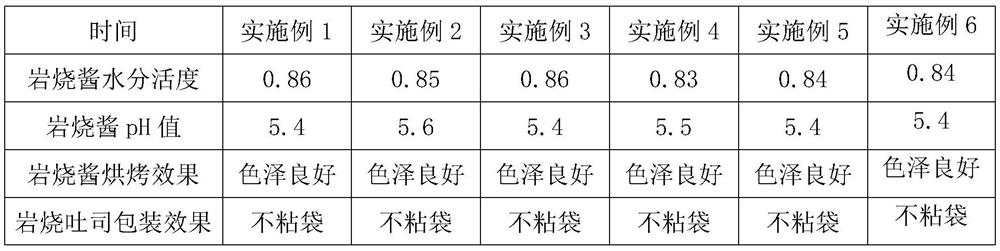

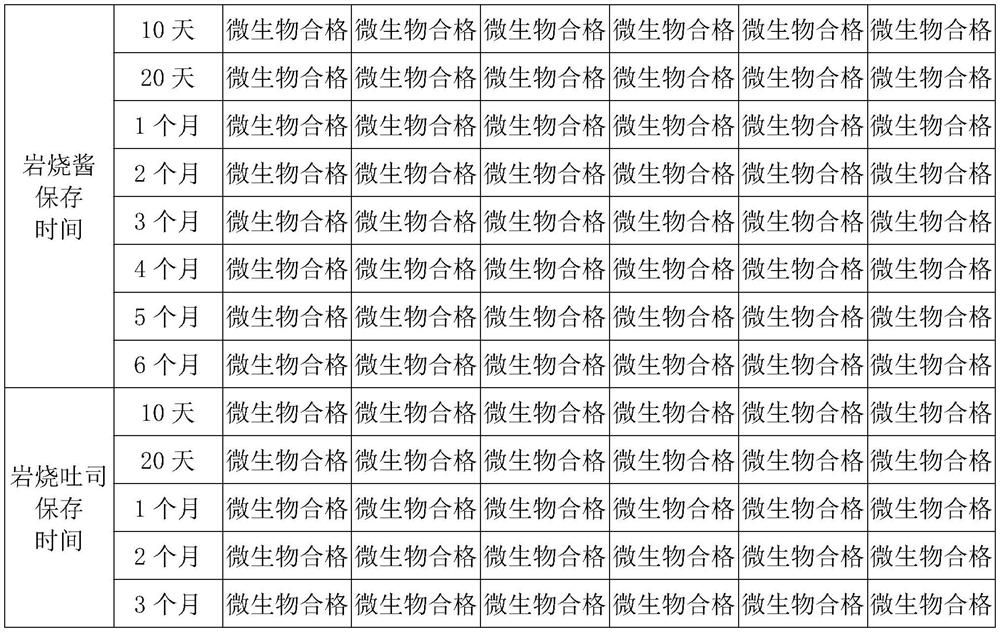

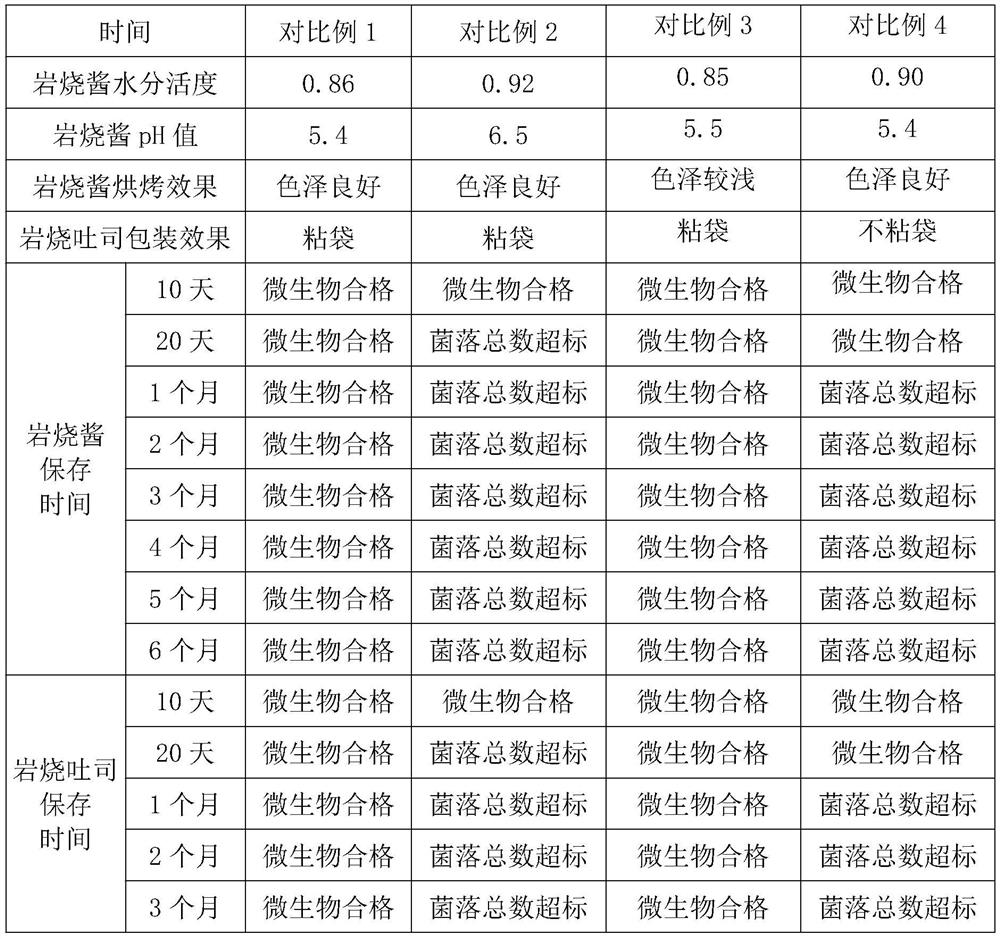

Examples

preparation example Construction

[0056] A kind of preparation method of rock sauce, is used for preparing above-mentioned rock sauce, and this preparation method comprises the following steps:

[0057] (1) By weighing each raw material according to the formula ratio, the raw material is divided into liquid raw material and powder raw material;

[0058] (2) After the liquid raw material and the powder raw material are mixed uniformly respectively, the powder raw material is added to the liquid raw material to obtain a mixed raw material;

[0059] (3) Add the mixed raw materials into the high-shear emulsification pump, and slowly add the heated palm oil at 24°C to the high-shear emulsification pump to disperse evenly, and obtain the crude rock sauce;

[0060] (4) Add the rough product of rock roast sauce to a high-pressure homogenizer for homogenization, then add it to a scraped surface heat exchanger for gelatinization and sterilization treatment, and after cooling, automatically fill to obtain rock roast sauc...

Embodiment 1

[0071] A rock-burning sauce, in parts by weight, raw materials of the rock-burning sauce include 340 parts of pure water, 250 parts of palm oil at 24°C, 50 parts of glucose, 70 parts of white granulated sugar, 40 parts of trehalose, 25 parts of whole milk powder, corn 10 parts of starch, 30 parts of hydroxypropyl distarch phosphate, 0.5 parts of carrageenan, 1 part of microcrystalline cellulose, 1 part of xanthan gum, 100 parts of fructose syrup, 50 parts of sorbitol liquid, 30 parts of glycerin, 20 parts of gel-type whey protein powder, 5 parts of gel-type egg white powder, 6 parts of edible salt, 0.5 parts of potassium sorbate, 0.3 parts of sodium dehydroacetate, 8 parts of cheese powder, β-carotene (1% content) 1.4 0.07 parts of disodium edetate, 1.6 parts of citric acid, and 3 parts of food flavor.

[0072] The preparation method of this rock sauce comprises the following steps:

[0073] (1) After mixing the liquid raw material and the powder raw material in the above-men...

Embodiment 2

[0077] In parts by weight, the raw materials of rock roast sauce in this embodiment include 280 parts of pure water, 350 parts of palm oil at 24°C, 50 parts of glucose, 70 parts of white granulated sugar, 40 parts of trehalose, 25 parts of whole milk powder, and 10 parts of cornstarch. 20 parts of hydroxypropyl distarch phosphate, 0.5 parts of carrageenan, 2 parts of microcrystalline cellulose, 1 part of xanthan gum, 100 parts of fructose syrup, 50 parts of sorbitol liquid, 30 parts of glycerin, gel type 25 parts of whey protein powder, 5 parts of gel-type egg white powder, 6 parts of edible salt, 0.5 parts of potassium sorbate, 0.3 parts of sodium dehydroacetate, 5 parts of cheese powder, 1.4 parts of β-carotene (1% content), 0.07 parts of disodium edetate, 1.6 parts of malic acid, and 2 parts of food essence.

[0078] The preparation method of this rock sauce comprises the following steps:

[0079] (1) After mixing the liquid raw material and the powder raw material in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com