Preparation method of hydrophobic composite anti-corrosion coating and application thereof

A composite coating and anti-corrosion technology, which is applied in the preparation of inorganic nano-filler-epoxy resin hydrophobic composite anti-corrosion coating, and in the field of corrosion protection of metal materials, can solve the problem that the corrosion protection effect of resin coating is difficult to maintain, and achieve Improves anti-corrosion effect, improves thermal stability, and enhances corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A method for preparing a hydrophobic composite anti-corrosion coating disclosed by the present invention comprises the following steps:

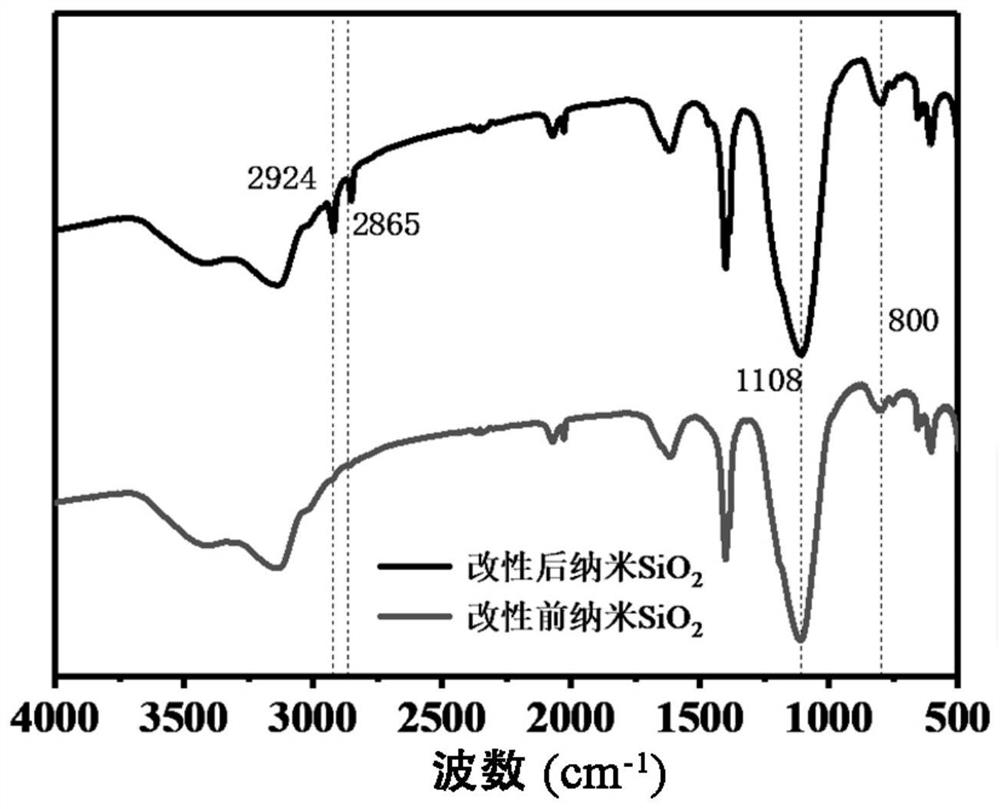

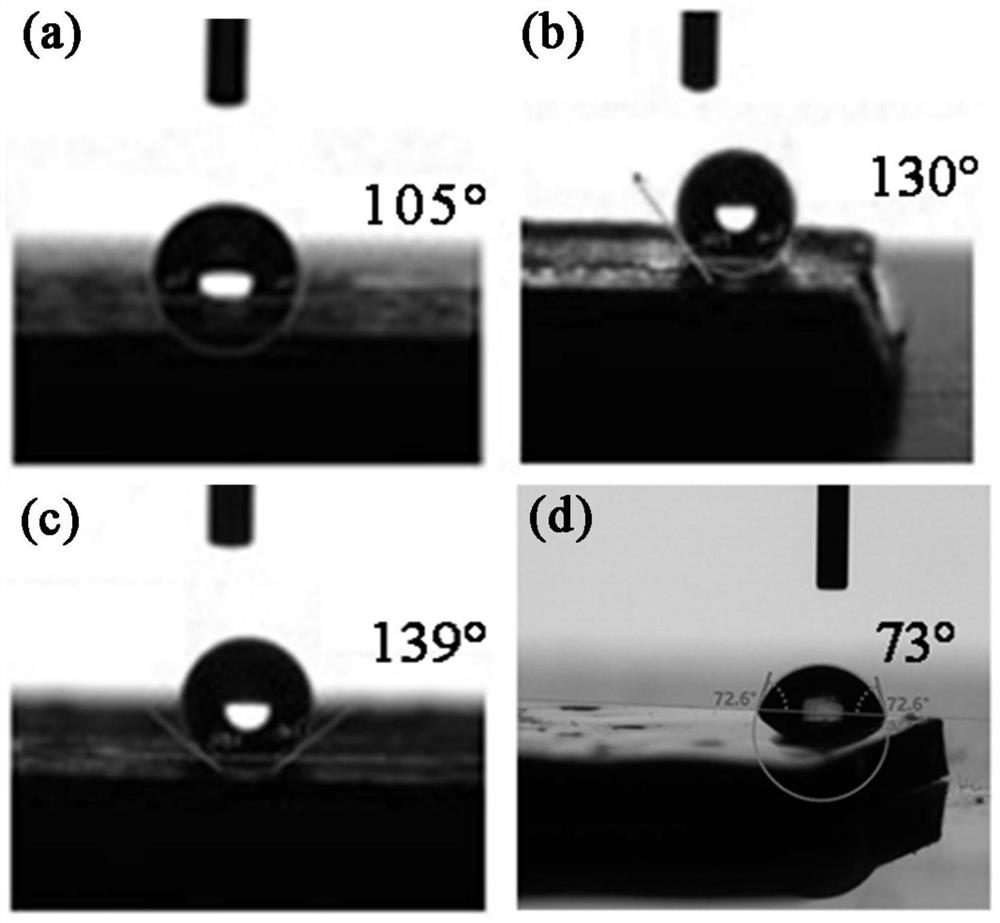

[0032] (1) Using octadecyltrichlorosilane to treat inorganic nanoparticles SiO 2 、TiO 2 Modification to obtain inorganic nano fillers with hydrophobic properties;

[0033] (2) mixing inorganic nano filler with epoxy resin and curing agent, adding a certain amount of acetone diluent to obtain composite coating material;

[0034] (3) Coating the composite coating material on the surface of the copper substrate by roller coating, and obtaining the inorganic nano filler-epoxy resin hydrophobic composite anti-corrosion coating after curing.

[0035] Wherein, the hydrophobic modification of the inorganic nanoparticles specifically includes processes such as modification, centrifugation, washing, and drying. More specifically, the mass of inorganic nanoparticles added during the modification process is 2-4g, absolute ethanol is 50-100mL, ...

Embodiment 1

[0038] Mix epoxy resin and polyamide resin curing agent in a mass ratio of 2:1, add 10wt.% modified nano-TiO 2 Particles, and 2wt.% acetone diluent was added, stirred and mixed at room temperature to obtain a uniform composite coating emulsion material.

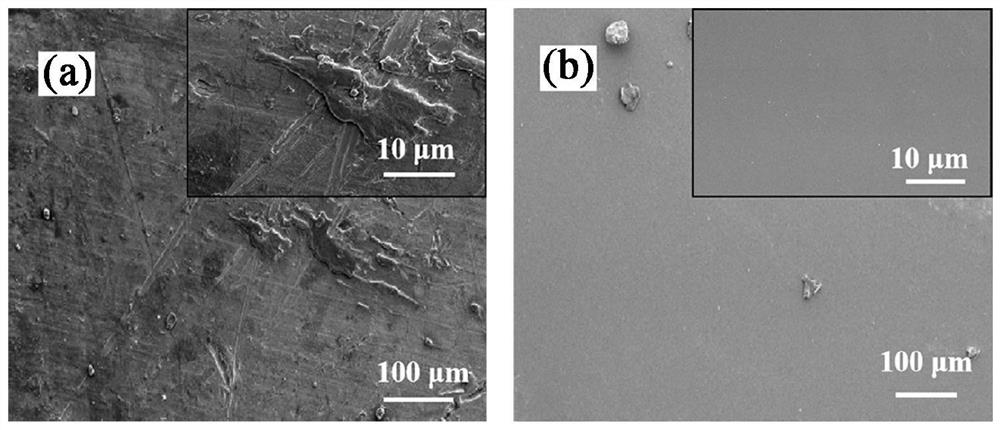

[0039] Use 240, 800, 1200 mesh silicon carbide sandpaper to polish the surface of the metal copper substrate with a size of 5mm × 5mm in sequence, then wash and degrease with deionized water, acetone and ethanol in sequence, and finally dry;

[0040] Use a wire bar coater to roll-coat the above-mentioned composite coating emulsion material on the surface of the copper substrate after treatment. The thickness of the roll-coating is 30 μm, the curing temperature is 80 ° C, and the curing time is 3 hours. Finally, TiO 2 Nanoparticle filler-epoxy resin hydrophobic composite anticorrosion coating.

Embodiment 2

[0042] Mix epoxy resin and polyamide resin curing agent in a mass ratio of 2:1, add 30wt.% modified nano-TiO 2 particles, and adding 5wt.% acetone diluent, stirring and mixing at room temperature to obtain a uniform composite coating emulsion material.

[0043] Use a wire bar coater to roll-coat the above-mentioned composite coating emulsion material on the surface of the copper substrate after treatment. The thickness of the roll-coating is 80 μm, the curing temperature is 100 ° C, and the curing time is 5 hours. Finally, TiO 2 Nanoparticle filler-epoxy resin hydrophobic composite anticorrosion coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com