Protective layer of semiconductor photoelectric chip and production process of semiconductor

A technology for optoelectronic chips and manufacturing processes, applied in semiconductor lasers, semiconductor devices, sustainable manufacturing/processing, etc., can solve the problems of glue aging, loss of water vapor isolation ability, unusable reliability requirements, etc., to save space and cost, The effect of meeting reliability requirements and reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

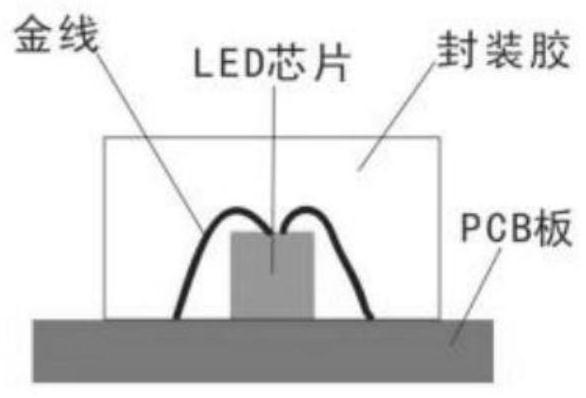

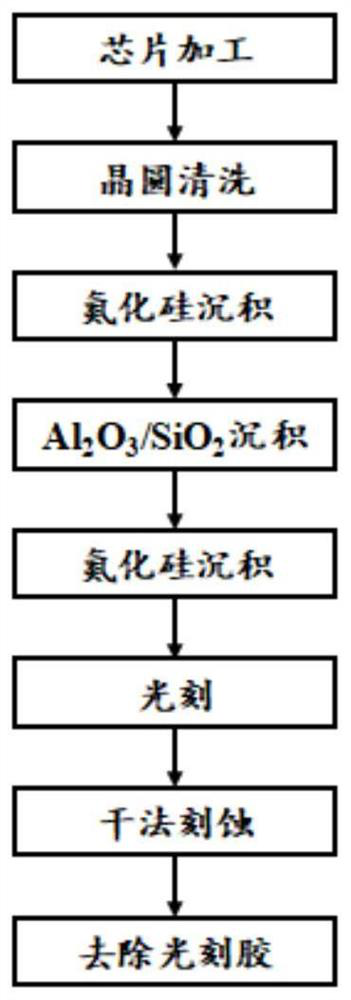

[0046] Taking the vertical cavity surface emitter as an example, silicon nitride-Al is deposited in the product process 2 o 3 / SiO 2 -Silicon nitride multilayer film is used as protective layer, and the relevant parameters of composition and structure of this protective film are as shown in table 1:

[0047] Table 1 Composition and structure of protective film

[0048] deposition sequence Film type membrane thickness Refractive index 1 Silicon nitride 50 2.0 2 al 2 o 3

50 1.65 3 SiO 2

30 1.46 4 Silicon nitride 190 2.0

[0049] The prepared protective film can achieve a light reflectance of less than 1% at a wavelength of 850nm, so as to reduce the reflectance of the cavity facing the light of this wavelength.

[0050] The performance of the same laser without a protective film structure and the laser with a protective film structure was tested. The results show that the optical anti-reflection effect of the laser...

Embodiment 2

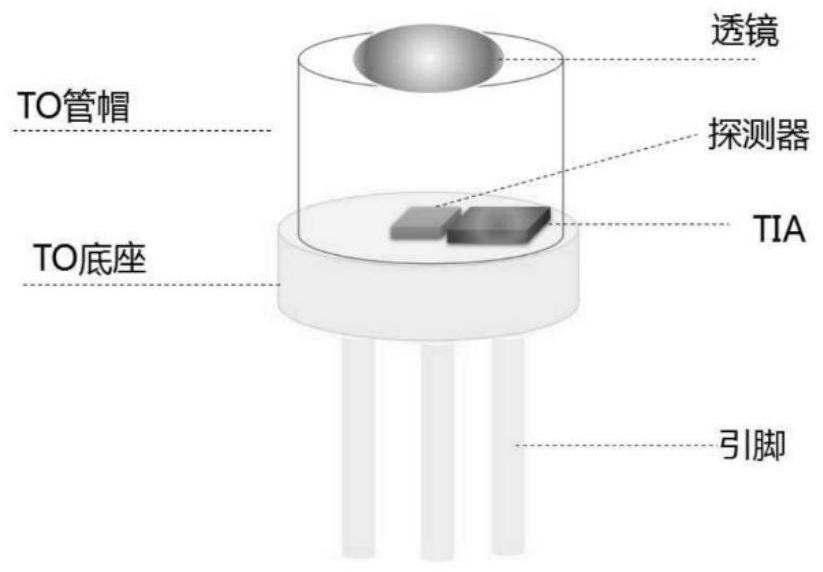

[0052] The photodiode is used as a device that receives light and converts it into a current signal, and silicon nitride-Al is deposited in the product process 2 o 3 / SiO 2 / Al 2 o 3 / SiO 2 -Silicon nitride multilayer film is used as protective layer, and the relevant parameters of composition and structure of this protective film are as shown in table 2:

[0053] Table 2 Composition and structure of protective film

[0054] deposition sequence Film type membrane thickness Refractive index 1 Silicon nitride 30 2.0 2 al 2 o 3

50 1.65 3 SiO 2

30 1.46 4 al 2 o 3

50 1.65 5 SiO 2

30 1.46 6 Silicon nitride 40 2.0

[0055] The prepared protective film can achieve a light reflectance of less than 1% at a wavelength of 1550nm, which improves the light conversion efficiency of the photodiode, and the dark current, responsivity and frequency characteristics of the photodiode without the protectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com