Preparation method of molecular sieve catalyst, catalyst and application thereof

A molecular sieve and catalyst technology, applied in the field of preparation of molecular sieve catalysts, can solve the problem of low metal loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

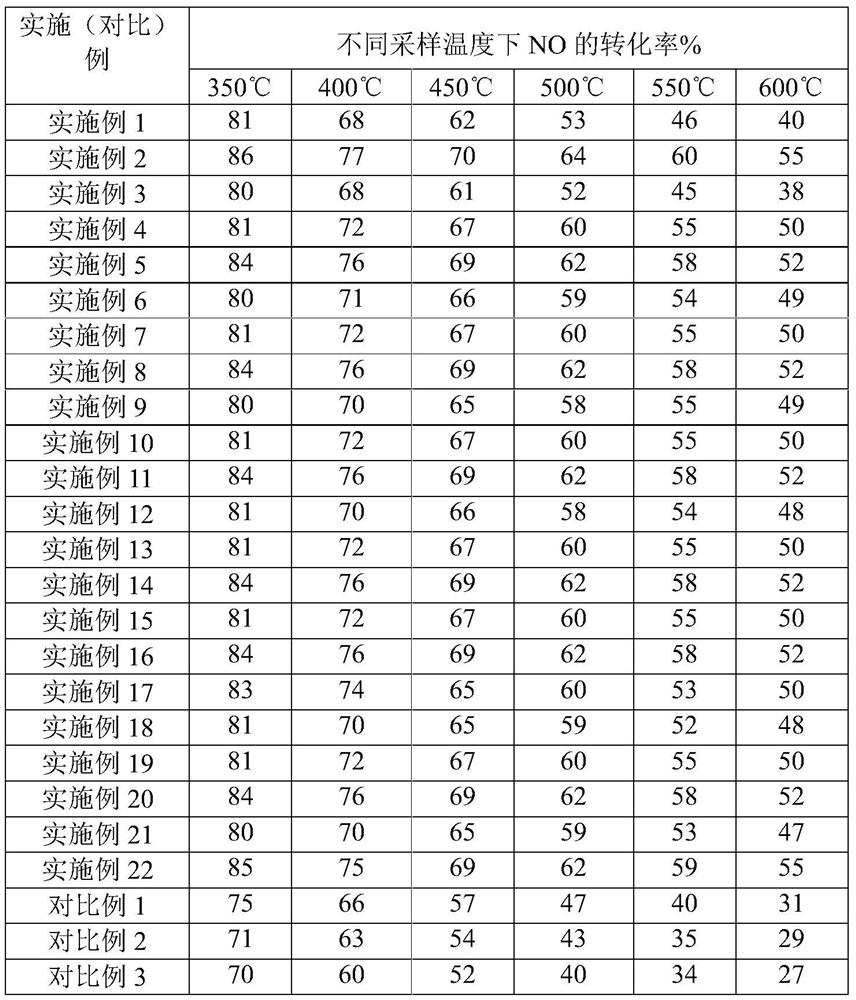

Examples

preparation example Construction

[0023] In a typical implementation of the present application, a method for preparing a molecular sieve catalyst is provided, the preparation method comprising: step S1, mixing the molecular sieve carrier with the precursor of the metal active component to obtain a dry mixture; step S2 , performing high-energy ball milling on the dry mixture and balls in a ball mill to obtain a ball-milled system; and step S3, roasting the ball-milled system to obtain a molecular sieve catalyst, wherein the speed of the high-energy ball mill is 100-2000r / min.

[0024] In this application, firstly, the molecular sieve is directly mixed with the precursor of the metal active component to obtain a dry blend. Then, the high-energy ball milling method is used to refine the crystal grains of the precursor of the metal active component and the molecular sieve, improve the distribution uniformity of the precursor of the metal active component and the molecular sieve, and enhance the bonding strength of...

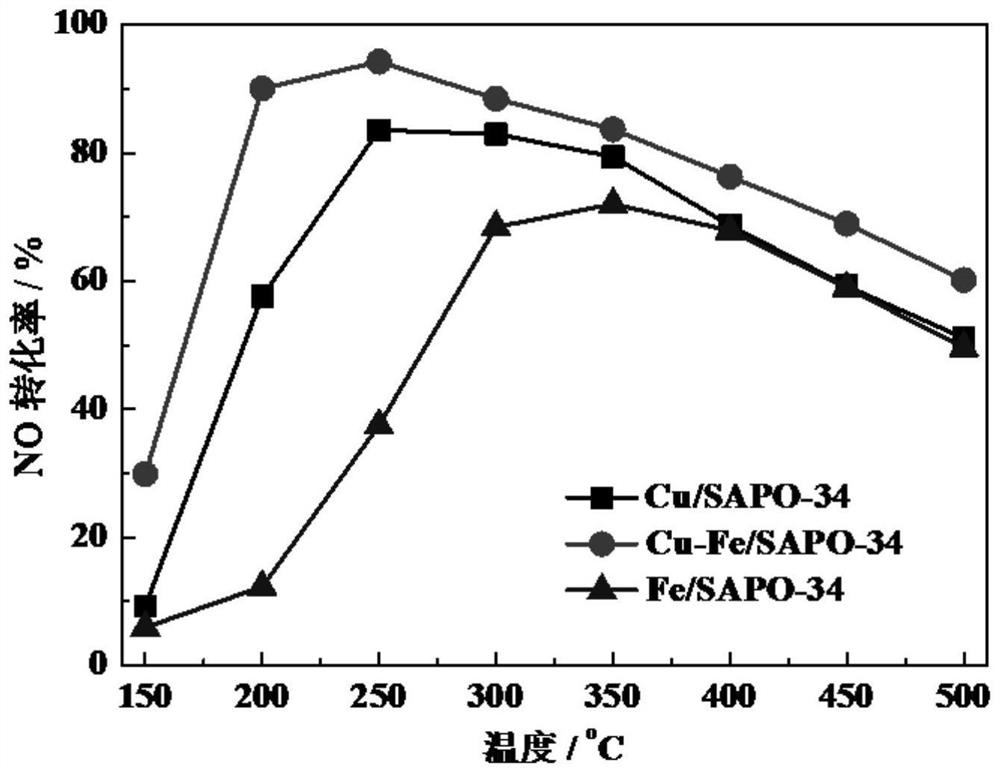

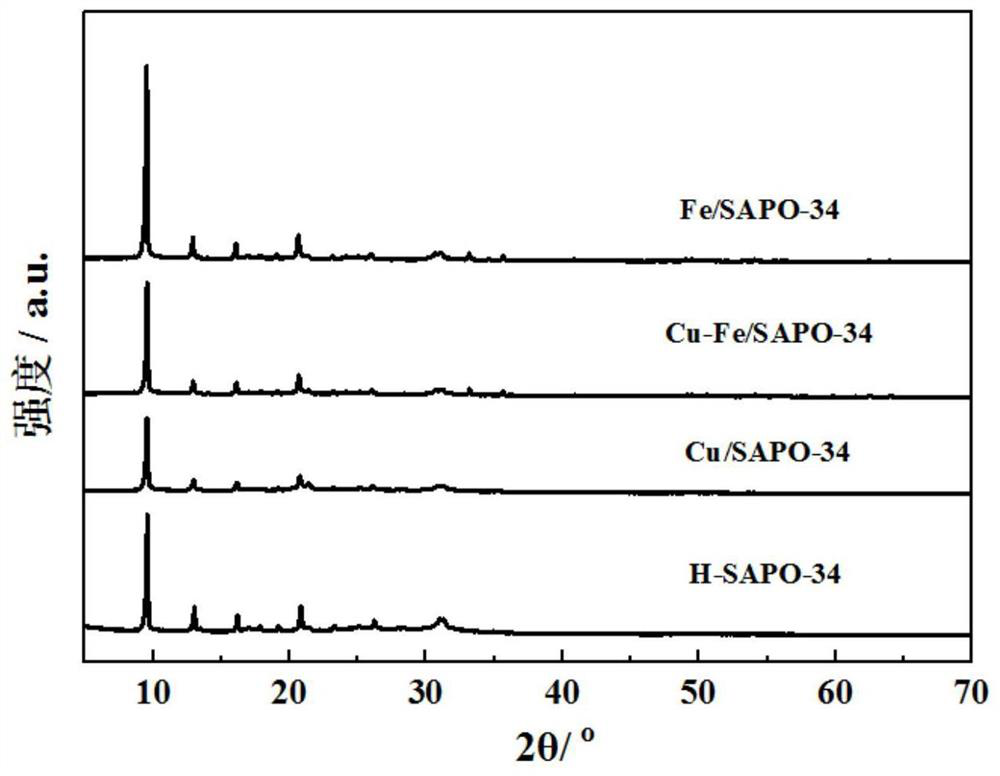

Embodiment 1

[0041] Place 2 g of SAPO-34 molecular sieve and 0.19 g of cupric chloride dihydrate into an agate mortar and mix thoroughly to obtain a dry mixture; mill the dry mixture in a ball mill for 30 minutes to obtain a milled system, wherein the ball The particle size is 6mm, the weight ratio of the balls in the ball mill to the SAPO-34 molecular sieve carrier is 25, and the speed of the ball mill is 1000r / min; then the ball milled system is put into the muffle furnace, and the air atmosphere is 800°C for 4h Calcined to obtain a copper-based molecular sieve catalyst, denoted as Cu / SAPO-34. The copper-based molecular sieve catalyst includes a SAPO-34 molecular sieve carrier and copper ions, wherein the copper ion is 3.5 wt% of the SAPO-34 molecular sieve carrier. In addition, SAPO-34 molecular sieve was provided by Nanjing Xianfeng Nano Material Technology Co., Ltd. (the same below).

Embodiment 2

[0043] Place 2 g of SAPO-34 molecular sieve, 0.19 g of copper chloride dihydrate, and 0.25 g of ferrous chloride tetrahydrate into an agate mortar and mix thoroughly to obtain a dry mixture; mill the dry mixture in a ball mill for 30 minutes The system after ball milling is obtained, wherein the particle diameter of the ball mill is 6mm, the weight ratio of the ball mill in the ball mill to the SAPO-34 molecular sieve carrier is 25, and the rotating speed of the ball mill is 1000r / min; then the system after ball milling is put into the muffle furnace , Roasted at 800°C in an air atmosphere for 4h to obtain an iron-based molecular sieve catalyst, which is denoted as Cu-Fe / SAPO-34. The molecular sieve catalyst comprises a SAPO-34 molecular sieve carrier, copper ions and iron ions, wherein the copper ion is 3.48wt% of the SAPO-34 molecular sieve carrier, and the iron ion is 3.47wt% of the SAPO-34 molecular sieve carrier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com