Efficient rare earth complex light-emitting film as well as preparation method and application thereof

A technology of rare earth complexes and luminescent thin films, applied in luminescent materials, chemical instruments and methods, photovoltaic power generation, etc., can solve problems such as low utilization rate, life attenuation, loss, etc., and achieve the goal of reducing land area and improving photoelectric conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

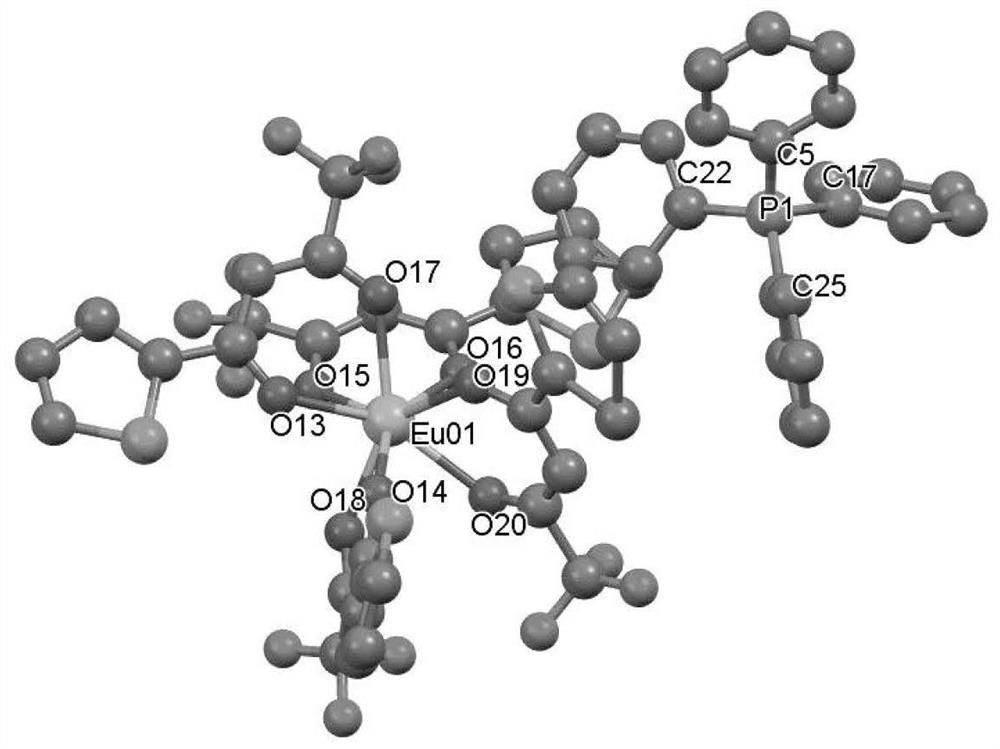

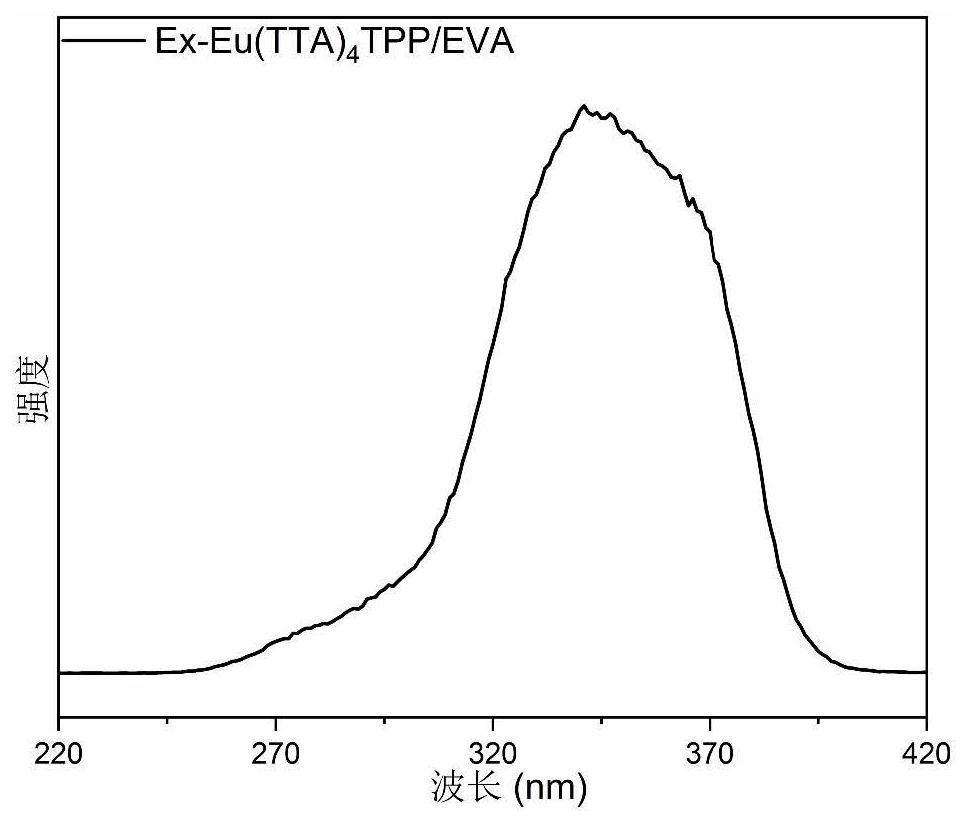

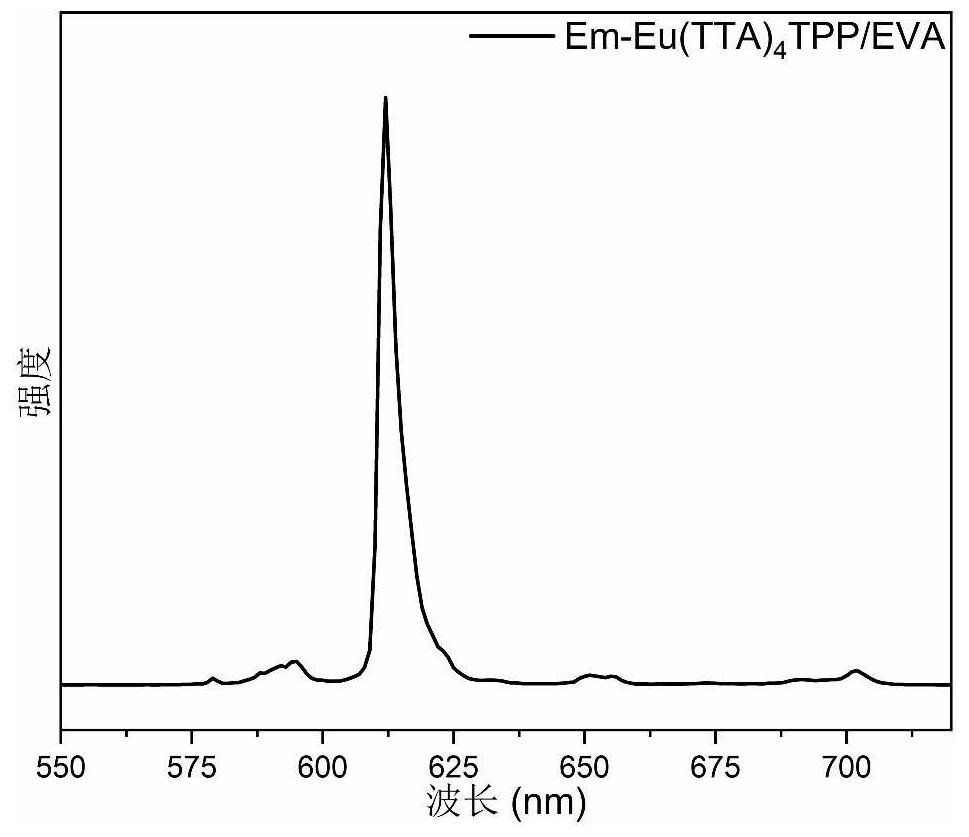

[0040] 1) Dissolve 4mmol of TTA in 5ml of ethanol solution, add 4mmol of 0.1mol / L NaOH in absolute ethanol to deprotonate the TTA ligand, reflux at 60°C, and add 1mmol of 0.1mol / L EuCl 3 Ethanol solution, after two hours of reaction, add 2ml of 0.5mol / L tetraphenylphosphine chloride aqueous solution to it, react for two hours and cool to room temperature, add a large amount of distilled water to obtain a precipitate, then wash and dry the precipitate, Recorded as Eu(TTA) 4 TPP;

[0041] 2) Eu(TTA) in step 1) 4 2.5mg of TPP complex was dissolved in 20ml of dichloromethane solvent;

[0042] 3) Add 5g of EVA to 50ml of toluene solution, condense and reflux at 80°C, add the solution obtained in 2) after the solution is cooled, and perform ultrasonic stirring; the doping ratio of the impurity medium in the polymer matrix is 0.05%

[0043] 4) Drop the solution of process 3) into a petri dish with a diameter of 17cm, and place it on a plate at 100°C to heat it to be cured to fo...

Embodiment 2

[0053] 1) 4mmol of NTA was dissolved in 5ml of ethanol solution, and 4mmol of NaOH in absolute ethanol solution was added to deprotonate the NTA ligand. The remaining experimental operations were the same as step 1) in Example 1, and the dried luminescent material was recorded as Eu(NTA ) 4 TPP; 2) Eu(NTA) in step 1) 4 TPP complex 0.05mmol is dissolved in the dichloromethane solvent of 20ml; 3), 4) step is with the step 3) in the embodiment 1, 4) gained film is marked as Eu(NTA) 4 TPP-EVA film. The thin film, silicon-based solar cell, base plate and photovoltaic glass are packaged by vacuum lamination.

Embodiment 3

[0055] 1) 4mmol of HFA was dissolved in 5ml of ethanol solution, and 4mmol of NaOH in absolute ethanol solution was added to deprotonate the HFA ligand. The remaining experimental operations were the same as step 1) in Example 1, and the dried luminescent material was recorded as Eu(HFA ) 4 TPP; 2) Eu(HFA) in step 1) 4 TPP complex 0.05mmol is dissolved in the dichloromethane solvent of 20ml; 3), 4) step is with the step 3) in the embodiment 1, 4) gained film is marked as Eu(HFA) 4 TPP-EVA film. The thin film, silicon-based solar cell, base plate and photovoltaic glass are packaged by vacuum lamination.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com