Method for efficiently degrading pollutants in oil refining wastewater by using photosynthetic bacterium system

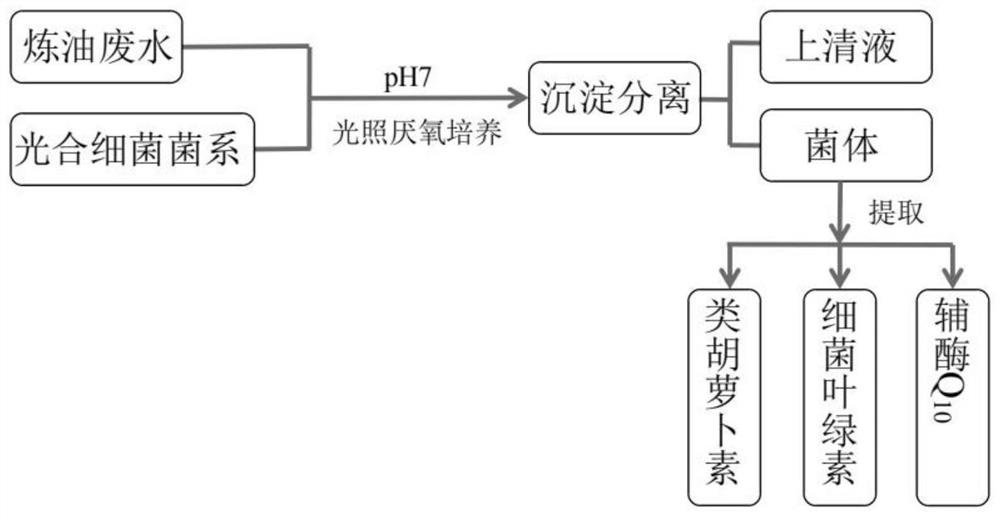

A technology for oil refining wastewater and photosynthetic bacteria is applied in the field of sewage treatment and resource utilization, which can solve the problems of complex process and strong light conditions, and achieve the effect of simple process, high-efficiency degradation, and reduction of hardware input cost and time cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, the method for efficiently degrading pollutants in oil refinery wastewater using photosynthetic bacteria strains comprises the following steps:

[0032](1) Take 5g of soil in the anoxic area of the lake that can be exposed to direct sunlight, place it in a 100mL graduated cylinder, add sterilized enrichment medium to 95mL, then add 5mL of liquid paraffin, place it in an incubator, and set the temperature 30°C, light intensity 3000-4000lux, culture for 7 days, when red bacteria adhere to the soil surface, the culture medium changes from colorless to red, take 5mL of liquid and transfer to a new culture medium, enrich repeatedly until the color turns purple or deep red. The composition of the enrichment medium is: sodium acetate: 3g / L, sodium propionate: 0.3g / L, ammonium sulfate: 0.3g / L, calcium chloride: 0.1g / L, dipotassium hydrogen phosphate: 0.3g / L, Potassium dihydrogen phosphate: 0.5g / L, manganese sulfate: 0.025g / L, ferrous sulfate: 0.005g / L, ye...

Embodiment 2

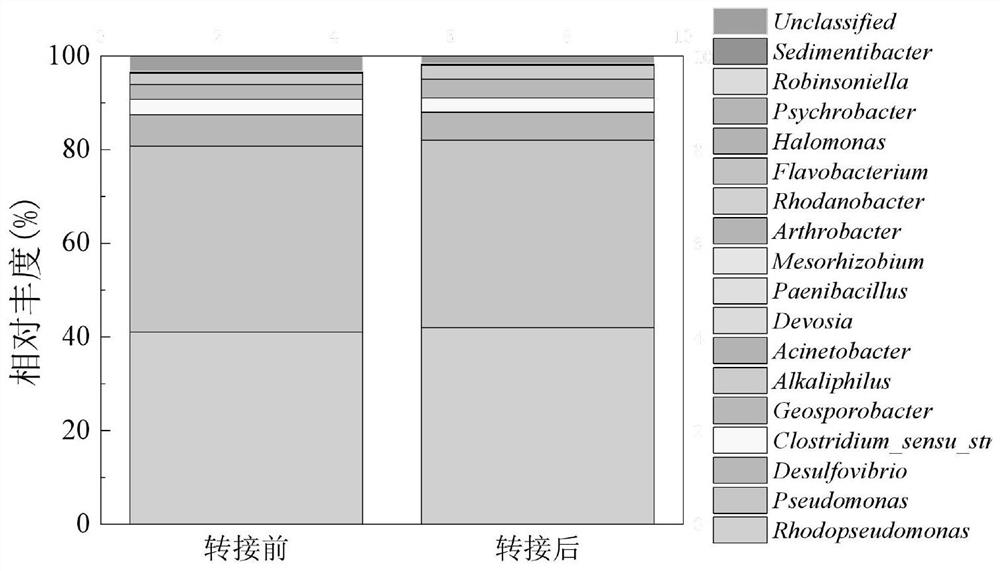

[0038] In an oil refinery in Panjin City, Liaoning Province, the indicators of oil refining wastewater are: COD: 16181mg / L, NH 4 + -N: 771mg / L, NO 3 - -N: 165mg / L, NO 2 - -N: 21mg / L, chroma: 15000, conductivity: 4.14mS / cm. The refinery wastewater contains more phenols and hydrocarbons, pH6.14, neutral, and opaque. The refinery wastewater is diluted 12 times to make it transparent. After dilution, the pH is 6.8, and the pH is adjusted to 7.0. Get diluted appropriate amount of oil refinery wastewater and put it in a conical flask, and then add 30% dosage (per 1000L of diluted oil refinery wastewater, add 300L of bacteria liquid after centrifugation, the concentration of the two strains in the bacteria liquid is 102mg / L), add photosynthetic bacteria strains, light anaerobic culture at 30°C, set the light intensity gradient as: 500, 2000, 4000, 6000 and 8000lux, after a period of cultivation, carry out precipitation separation, and measure the pollutant indicators in the sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com