Carbon dot composite conductive agent and preparation method and application thereof

A technology of composite conductive agent and carbon dots, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. Conductivity and other issues, to achieve the effect of prolonging mixing stability, inhibiting agglomeration, and ensuring conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

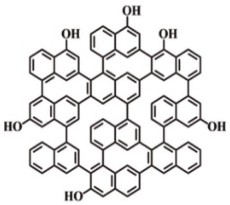

[0036] (1) Preparation of conductive carbon dot materials:

[0037] Add 1,3-dihydroxynaphthalene and potassium periodate into ethanol solvent in a ratio of 1:4 to dissolve, then transfer the solution to a high-temperature and high-pressure reactor and heat it to 180°C for 2 hours to react to synthesize the precursor. Naturally cooled to room temperature, the purified precursor conductive carbon dot material was obtained by dialysis.

[0038] (2) Preparation of carbon dot composite conductive agent:

[0039]The mass ratio of conductive carbon dot materials, multi-walled carbon nanotubes: polyvinylidene fluoride is 5:1:10;

[0040] Mix conductive carbon dot materials and multi-walled carbon nanotubes at a mass ratio of 5:1, and then add the mixed mixture to polyvinylidene fluoride at a mass ratio of 6:10 in N-methylpyrrolidone solvent. Stir for 60 minutes to obtain a mixed solution with a mass concentration of 50wt%; continue to add N-methylpyrrolidone to dilute the mixed solu...

Embodiment 2

[0048] This embodiment provides a lithium-ion battery, and the difference from Embodiment 1 is step (3):

[0049] The mass ratio of nickel cobalt lithium manganese oxide: carbon dot composite conductive agent: polyvinylidene fluoride is 97.5:1:1.5 during the preparation process of the positive electrode sheet.

[0050] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0052] This embodiment provides a lithium-ion battery, and the difference from Embodiment 1 is step (3):

[0053] The mass ratio of nickel cobalt lithium manganese oxide: carbon dot composite conductive agent: polyvinylidene fluoride is 97.5:1.5:1 during the preparation process of the positive electrode sheet.

[0054] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com