Anti-fog film material and preparation method thereof

An anti-fog film, ethylene glycol dimethacrylate technology, applied in the field of anti-fog film materials and its preparation, can solve the problem of poor performance stability of anti-fog film, anti-fog effect and wear resistance need to be further improved and other issues, to improve the overall performance and performance stability, good anti-fog effect, and improve the effect of anti-fog performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

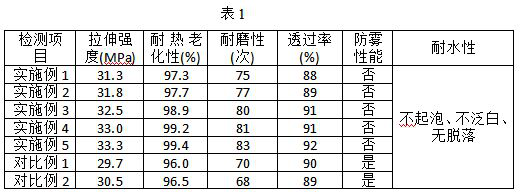

Examples

Embodiment 1

[0028] A method for preparing an anti-fog film material, comprising the steps of:

[0029] Step S1, allyl succinimidyl carbonate, ethylene glycol dimethacrylate, polyethylene glycol monoallyl ether, N-vinyl carbazole, vinyl β-cyclodextrin quaternary ammonium Salt, 2,3,5,6-tetrafluoroterephthalic acid, isocyanate-terminated polyurethane prepolymer, initiator, catalyst, and nano-titanium dioxide are added to the organic solvent, stirred evenly, and coated on the polytetrafluoroethylene board Or on a glass plate, placed in an inert gas atmosphere, dried at 85°C to constant weight, and then peeled off to obtain a polymer film;

[0030] Step S2, adding the polymer film made in step S1 to a mixed solution of methylvinylsilane and N-(4-cyano-3-trifluoromethylphenyl)methacrylamide, soaking for 2 After hours, take it out and place it in a blast oven at 80°C to dry to constant weight, and then carry out radiation grafting through radiation equipment at room temperature and nitrogen atm...

Embodiment 2

[0037] A method for preparing an anti-fog film material, comprising the steps of:

[0038]Step S1, allyl succinimidyl carbonate, ethylene glycol dimethacrylate, polyethylene glycol monoallyl ether, N-vinyl carbazole, vinyl β-cyclodextrin quaternary ammonium Salt, 2,3,5,6-tetrafluoroterephthalic acid, isocyanate-terminated polyurethane prepolymer, initiator, catalyst, and nano-titanium dioxide are added to the organic solvent, stirred evenly, and coated on the polytetrafluoroethylene board Or on a glass plate, placed in an inert gas atmosphere, dried at 87°C to constant weight, and then peeled off to obtain a polymer film;

[0039] Step S2, adding the polymer film made in step S1 to the mixed solution of methyl vinyl silfluorene and N-(4-cyano-3-trifluoromethylphenyl)methacrylamide, soaking for 2.5 After hours, take it out and place it in a blast oven at 83°C to dry to constant weight, and then carry out radiation grafting by radiation equipment at room temperature and nitroge...

Embodiment 3

[0046] A method for preparing an anti-fog film material, comprising the steps of:

[0047] Step S1, allyl succinimidyl carbonate, ethylene glycol dimethacrylate, polyethylene glycol monoallyl ether, N-vinyl carbazole, vinyl β-cyclodextrin quaternary ammonium Salt, 2,3,5,6-tetrafluoroterephthalic acid, isocyanate-terminated polyurethane prepolymer, initiator, catalyst, and nano-titanium dioxide are added to the organic solvent, stirred evenly, and coated on the polytetrafluoroethylene board Or on a glass plate, placed in an inert gas atmosphere, dried at 90°C to constant weight, and then peeled off the film to obtain a polymer film;

[0048] Step S2, adding the polymer film made in step S1 into a mixed solution of methylvinylsilane and N-(4-cyano-3-trifluoromethylphenyl)methacrylamide, soaking for 3 After hours, take it out and place it in a blast oven at 88°C to dry to constant weight, and then carry out radiation grafting through radiation equipment at room temperature and n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com