Binder composition for electrode, coating composition for electrode, electrode for power storage device, and power storage device

A technology for storage devices and compositions, applied in the direction of non-aqueous electrolyte batteries, negative electrodes, battery electrodes, etc., can solve problems such as peeling off, difficulty in maintaining electrode flexibility, dispersibility of electrode materials, and difficult realization of rheological control. Achieve the effects of high adhesion, high discharge performance and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

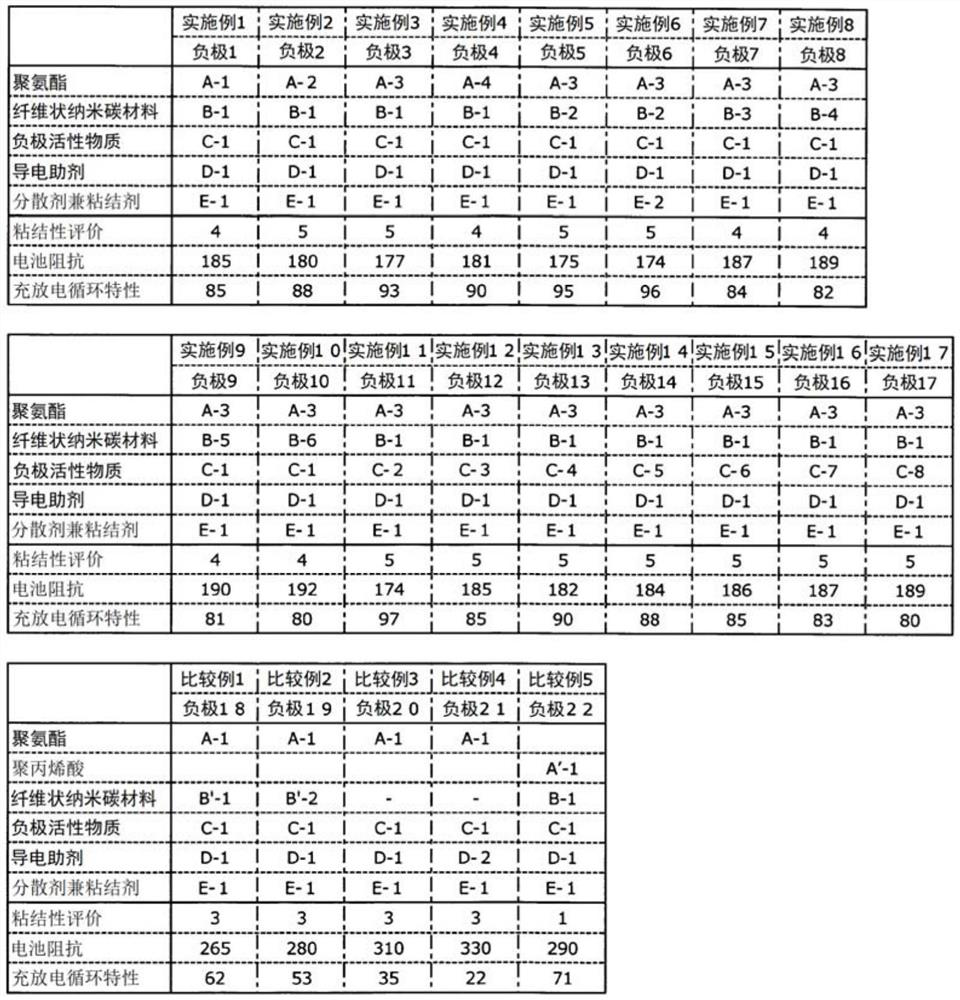

[0089] Next, examples will be described together with comparative examples. However, the present invention is not limited to these Examples. In addition, unless otherwise specified, "%" in an example means a mass basis.

[0090] Synthesis of Polyurethane Aqueous Dispersion

Synthetic example 1-1

[0091] (Synthesis Example 1-1) Synthesis of Aqueous Polyurethane Dispersion A-1

[0092] A polybutadiene polyol (manufactured by Idemitsu Kosan Co., Ltd., PolybdR-45HT, average hydroxyl value 46.5 mgKOH / g, active hydrogen number 2.32 ) 71.3 parts by mass, dimethylolpropionic acid (active hydrogen number 2) 4.2 parts by mass, 24.5 parts by mass of dicyclohexylmethane diisocyanate, 100 parts by mass of methyl ethyl ketone, reacted at 75°C for 4 hours to obtain free A methyl ethyl ketone solution of a urethane prepolymer having an isocyanate group content of 2.5% relative to the non-volatile content. This solution was cooled to 45° C., and 1.25 parts by mass of sodium hydroxide was added for neutralization, then 300 parts by mass of water was slowly added, and emulsified dispersion was performed using a homogenizer. Next, an aqueous solution obtained by diluting 1.6 parts by mass of ethylenediamine (active hydrogen number 2) with 100 parts by mass of water was added, and a chain...

Synthetic example 1-2

[0093] (Synthesis Example 1-2) Synthesis of Aqueous Polyurethane Dispersion A-2

[0094]A hydrogenated polybutadiene polyol (manufactured by CREY VALLEY, KRASOL HLBH-P3000, with an average hydroxyl value of 31.0 mgKOH / g and an active hydrogen number of 1.90) 73.9 parts by mass, dimethylolpropionic acid (active hydrogen number is 2) 4.6 parts by mass, 21.5 parts by mass of dicyclohexylmethane diisocyanate, 100 parts by mass of methyl ethyl ketone, reacted at 75°C for 4 hours, A methyl ethyl ketone solution of a urethane prepolymer having a free isocyanate group content of 2.1% based on the non-volatile content was obtained. This solution was cooled to 45° C., 3.5 parts by mass of triethylamine was added for neutralization, and then 300 parts by mass of water was slowly added to emulsify and disperse using a homogenizer. Next, an aqueous solution obtained by diluting 1.5 parts by mass of diethylenetriamine (active hydrogen number 3) with 100 parts by mass of water was added, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com