Drinking water ozone oxidation device and process with low NDMA generation

A technology for ozone oxidation and drinking water, which is applied in the direction of oxidized water/sewage treatment, water pollutants, water/sewage treatment, etc. It can solve the problems of large consumption and high price of hydrogen peroxide, and reduce the amount of production and the cost of raw materials Inexpensive, the effect of reducing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 Drinking water ozone oxidation device

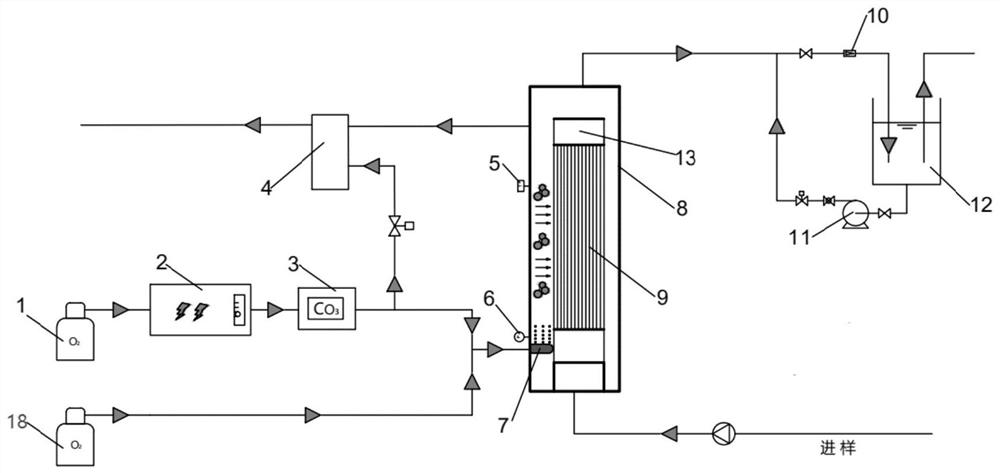

[0042] A kind of drinking water ozone oxidation device, with reference to figure 1 , including a glass reactor 8, a first oxygen generator 1, a second oxygen generator 18, an ozone generator 2, a gas concentration analyzer 3, an ozone tail gas decomposer 4, a backwash pump 11 and a water outlet bucket 12.

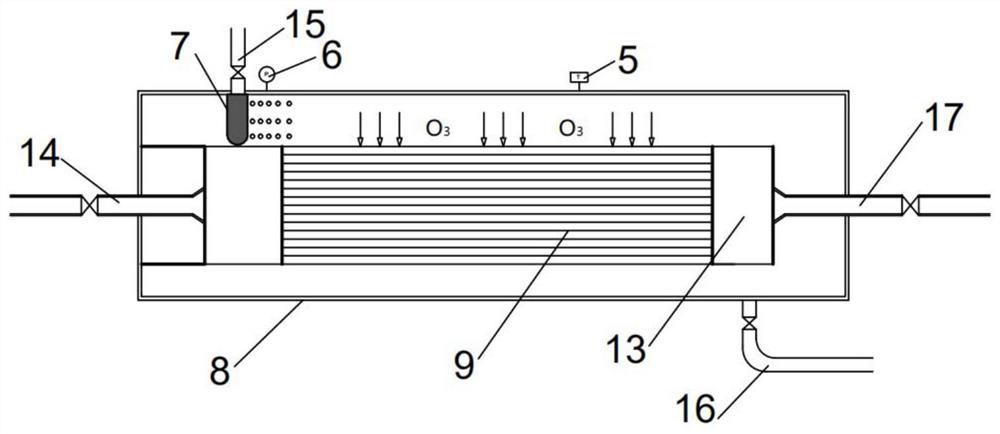

[0043] refer to figure 2 Specifically, the glass reactor 8 is set in a hollow cylindrical shape, and a thermometer 5 and a barometer 6 are arranged outside the glass reactor 8, so as to monitor the temperature and air pressure in the glass reactor 8. Both ends of the glass reactor 8 are respectively connected with a water inlet pipe 14 and an outlet pipe 17 , and the side wall of the glass reactor 8 is connected with an inlet pipe 15 and an air outlet pipe 16 . The glass reactor 8 is provided with an ozone distribution disc 7 , a polytetrafluoroethylene hollow fiber membrane 9 and a membrane module 13 . The ozo...

Embodiment 2

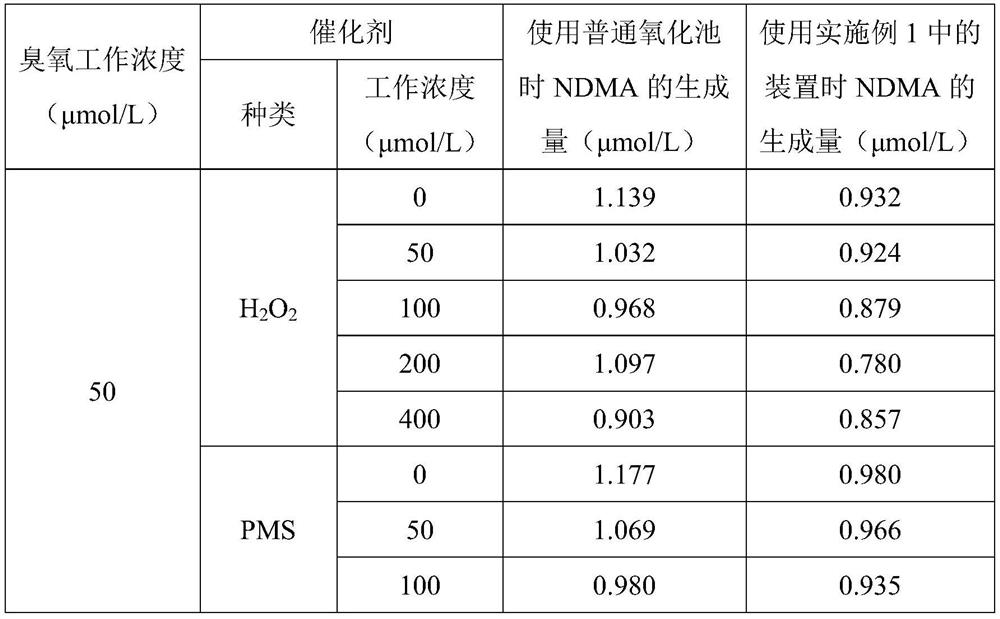

[0049] Embodiment 2 river water ozone oxidation test

[0050] Water from a river was taken, and the water sample was filtered with a 0.45 μm water membrane. The sampling and detection of natural water body adopts a combination of triple quadrupole gas chromatography-mass spectrometer, high performance liquid chromatography-triple quadrupole mass spectrometry, high performance liquid chromatography, pH meter, ultraviolet spectrophotometer, etc. The detection method shows that the water mainly contains nitrite nitrogen of 0.051-0.248mg / L, nitrate nitrogen of 2.02-2.83mg / L, pH of 7.00-7.26, and temperature of 25°C. In order to facilitate the detection of changes in NDMA content in water before and after ozone oxidation, DMZ (working concentration: 2 μmol / L) was added to the filtered water samples.

[0051] After the above water sample was subjected to ozonation, the NDMA in the sample was extracted by liquid-liquid extraction with methylene chloride, and the treated water was an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com