Sn-based brazing filler metal capable of realizing vertical stacking of chips and bonding method of Sn-based brazing filler metal

A vertical stacking, chip technology, applied in welding/cutting media/materials, nanotechnology for materials and surface science, welding media, etc., can solve problems such as inapplicability to high-density packaging of three-dimensional packaging electronic devices, different performance, etc. Achieve the effect of meeting high reliability requirements, high strength and service life, and high mechanical properties of solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

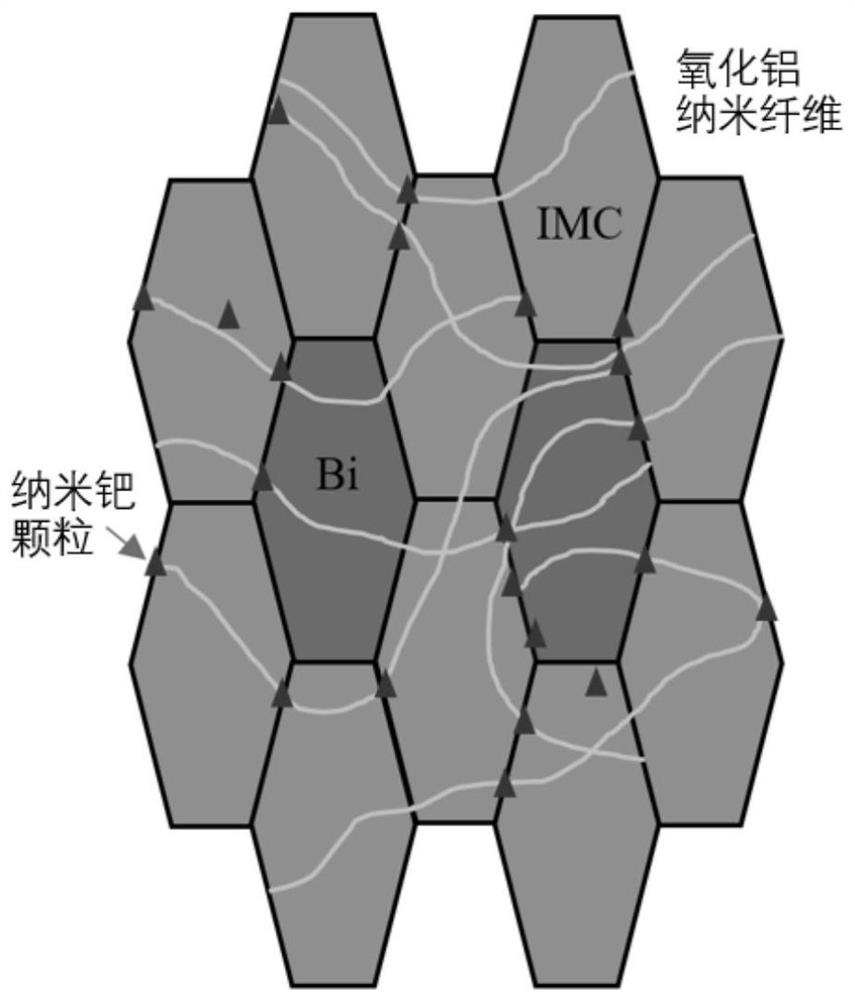

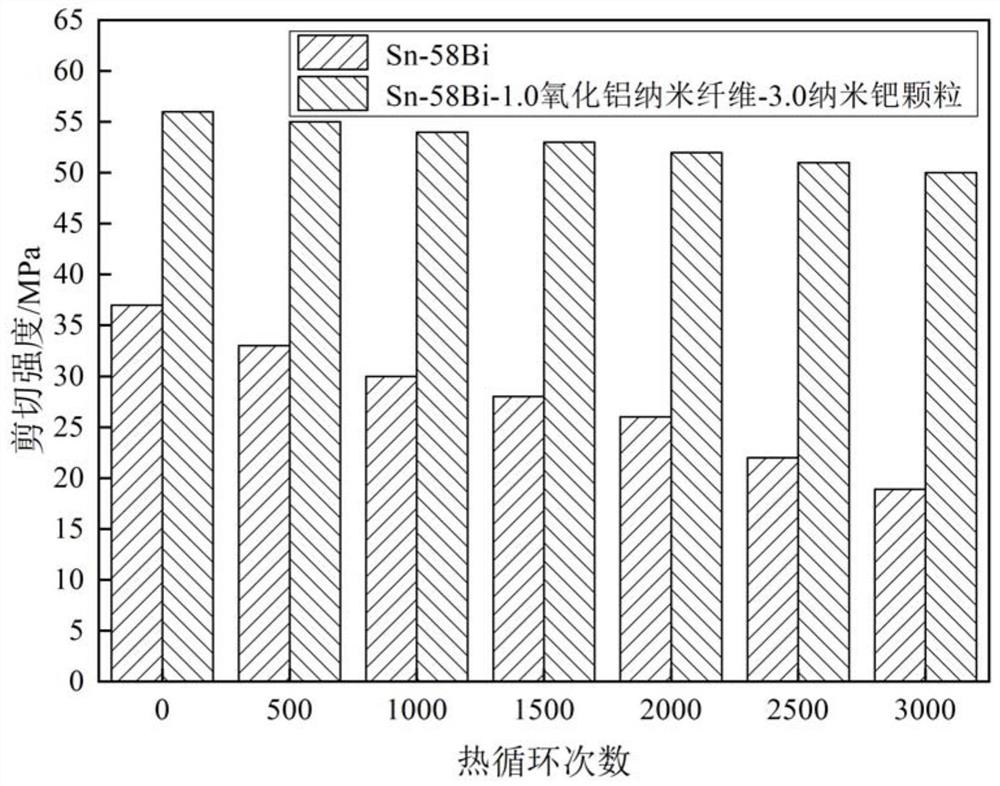

[0020] The composition and mass percentage of the Sn-based solder of the present invention are as follows: the content of aluminum oxide nanofibers is 1.0%, the content of nano-palladium particles is 3.0%, the content of Bi is 56%, and the balance is Sn.

[0021] Solder temperature performance test: under the premise of considering the experimental error, the solidus temperature is about 138.4 ℃, and the liquidus temperature is about 140.3 ℃.

Embodiment 2

[0023] The composition and mass percentage of the Sn-based solder of the present invention are as follows: the content of aluminum oxide nanofibers is 1.1%, the content of nano-palladium particles is 3.3%, the content of Bi is 56%, and the balance is Sn.

[0024] Solder temperature performance test: under the premise of considering the experimental error, the solidus temperature is about 138.5 ℃, and the liquidus temperature is about 140.6 ℃.

Embodiment 3

[0026] The composition and mass percentage of the Sn-based solder of the present invention are as follows: the content of aluminum oxide nanofibers is 1.2%, the content of nano-palladium particles is 3.6%, the content of Bi is 56%, and the balance is Sn.

[0027] Solder temperature performance test: under the premise of considering the experimental error, the solidus temperature is about 138.7 ℃, and the liquidus temperature is about 140.9 ℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com