Flow battery based on ternary eutectic solvent

A technology of deep eutectic solvent and liquid flow battery, applied in fuel cells, regenerative fuel cells, circuits, etc., can solve problems such as ion migration resistance, increase diffusion coefficient, increase electrochemical reaction speed, reduce mass transfer and Effect of loss of pump power etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

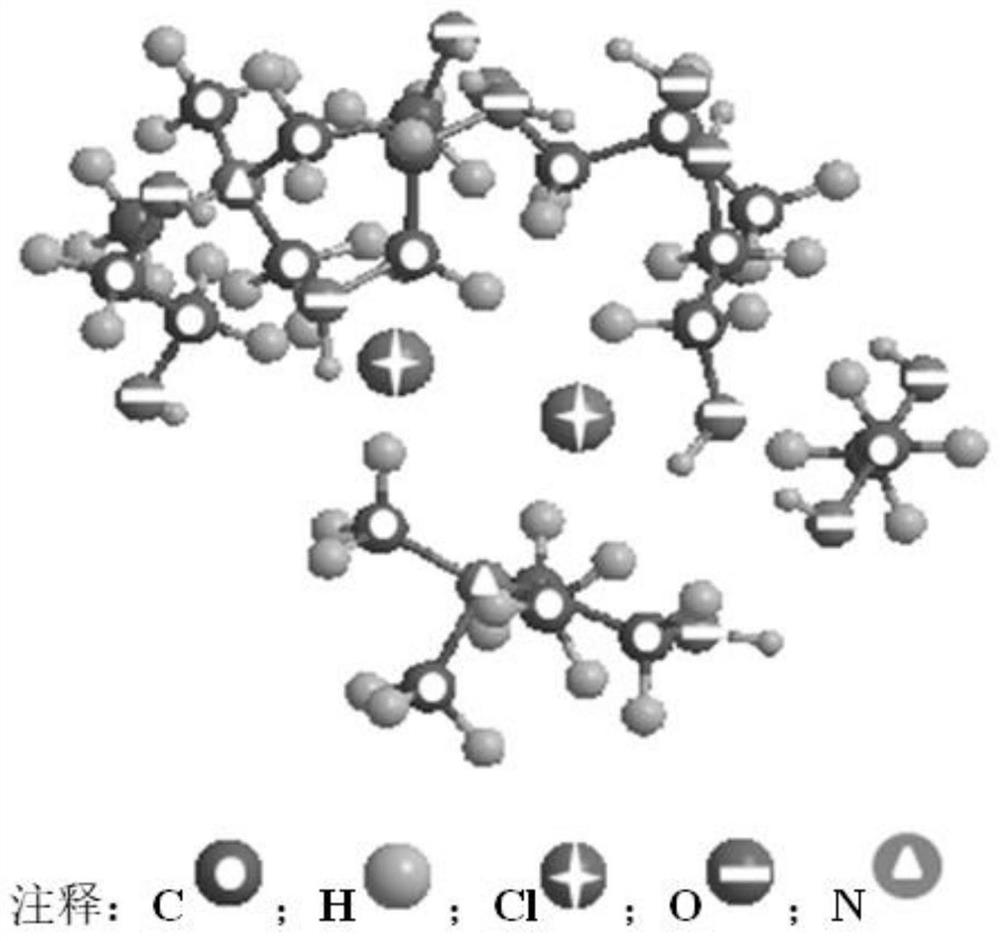

[0027] Choline chloride: ethylene glycol: glycerin according to the molar ratio of 1: 2: x (x = 0.1 ~ 1), prepared by magnetic heating and stirring at 100 ° C to obtain a transparent ternary deep eutectic solvent, cooled at room temperature spare. The prepared solvent should be sealed and stored in time to avoid contamination of the solvent by substances in the air.

[0028] Add active material FeCl to ternary deep eutectic solvent 3 ﹒ 6H 2 O, and heated and stirred at 100°C until it completely dissolved to form an orange-yellow electrolyte.

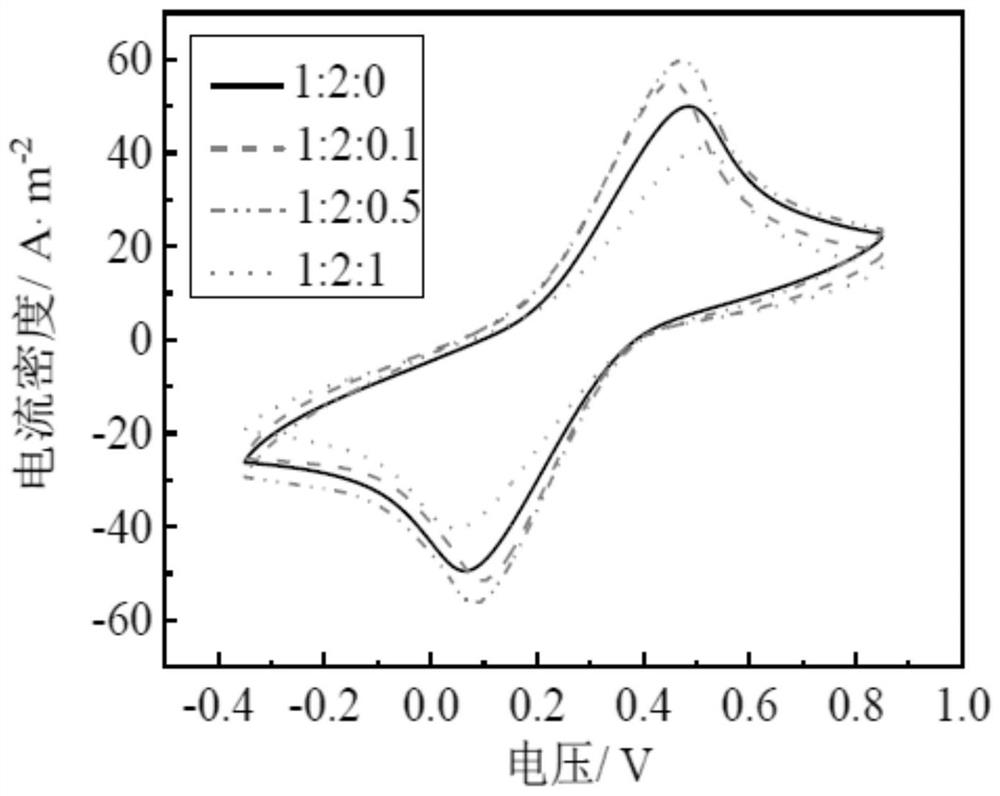

[0029] For the prepared electrolytes added with different molar ratios of glycerol at 50mV. the s -1 cyclic voltammetry

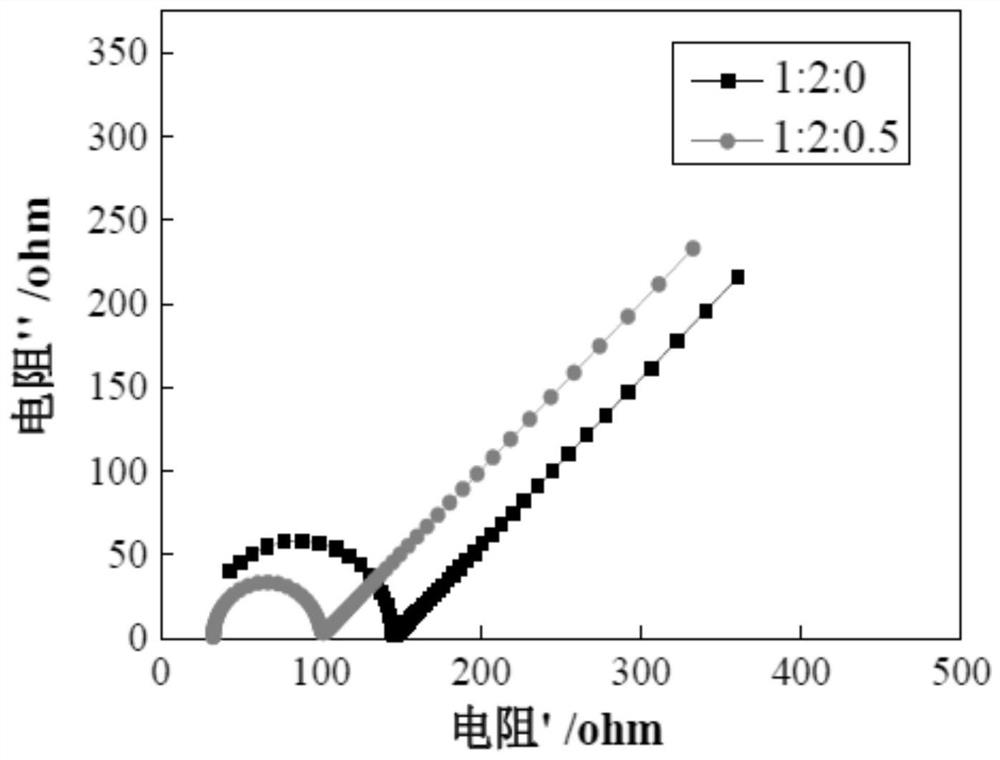

[0030] Line test, test data such as figure 2 shown. Viscometer and conductivity meter were used to test the changes in the physical properties of the electrolyte. The test results are shown in Table 1. Through combined analysis with the cycle test curve, when the molar ratio of glycerol is 0.5, the peak pote...

Embodiment 2

[0038] Prepare 0.1mol of ternary deep eutectic solvent as solvent. L -1 FeCl 2 ﹒ 4H 2 O Electrolyte, VCl 3 The electrolyte is stored in the positive and negative liquid storage tanks outside the flow battery respectively. The experimental device is as follows: Figure 4As shown, the main part of the flow battery is two current collectors made of graphite. The positive and negative electrodes are made of carbon felt, which are separated by Nafion212 ion exchange membrane. There is a 10mm X gap between each electrode and the graphite current collector. 10mm reaction area and 3mm thickness electrochemical reaction zone for the circulation of the liquid in the storage tank. Purge the connected flow battery pipeline with high-purity nitrogen for at least 20 minutes to avoid the influence of residual oxygen or water vapor in the pipeline. During the operation of the flow battery, through 25mL. min -1 The flow rate peristaltic pump circulates and pumps the electrolyte solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com