Supergravity device for efficient coupling reinforcement in liquid-liquid heterogeneous reaction and product two-phase separation process

A heterogeneous and phase-separated technology, applied in the chemical method, liquid separation, chemical/physical process, etc. of the liquid-liquid reaction, which can solve the problem of many coaxial rotating parts, long oil-water separation time, and increased energy consumption. and other problems to achieve the effect of efficient coupling enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

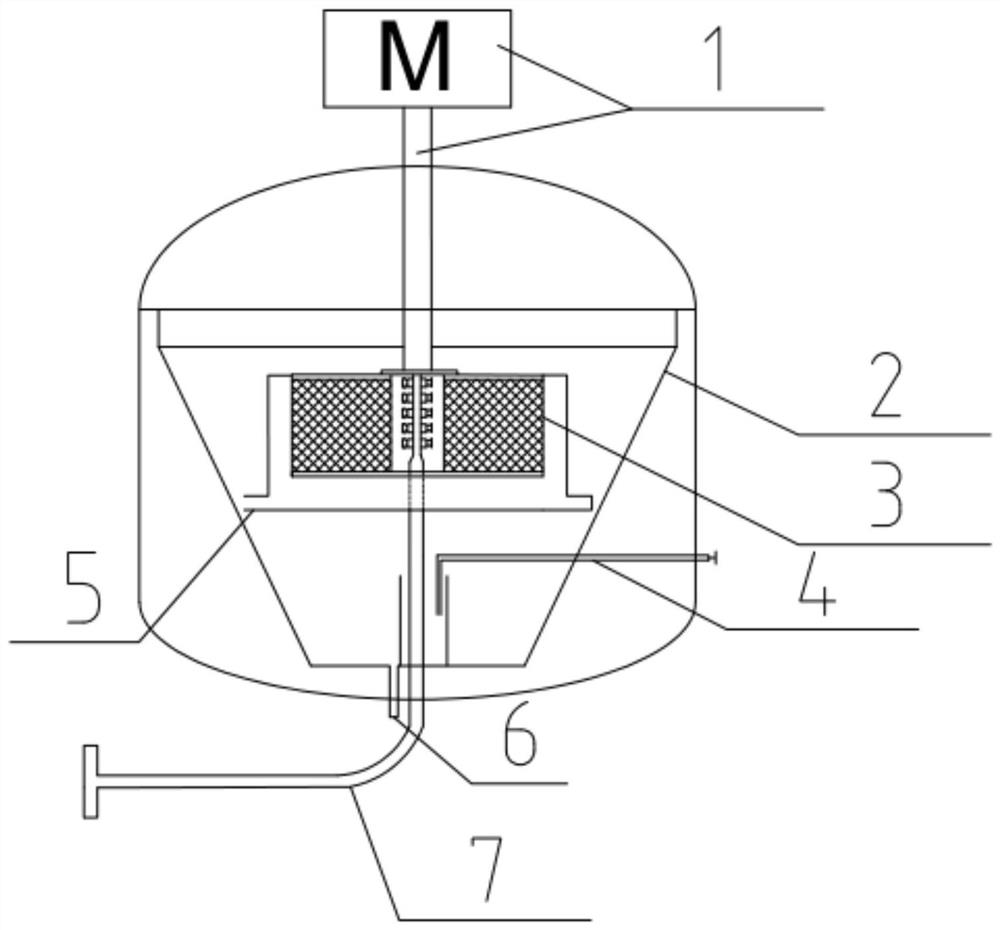

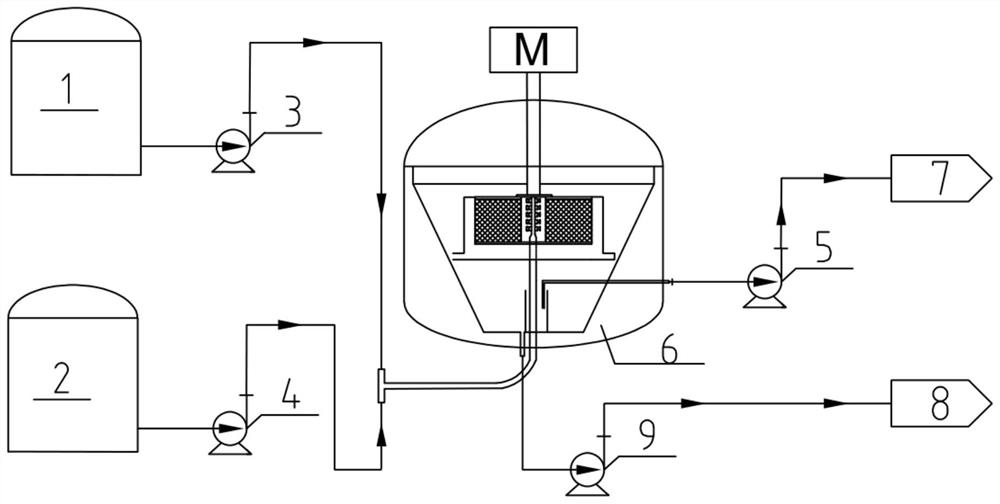

[0090] Adopt the equipment of the present invention and image 3 Shown system is to produce epichlorohydrin with dichloropropanol and sodium hydroxide aqueous solution as raw material, concrete steps and result are as follows:

[0091] Store the aqueous sodium hydroxide solution of mass fraction 4% in the light phase storage tank, store the chemically pure dichloropropanol liquid in the heavy phase storage tank, with the mass flow rate of 1kg / min and 150g / min respectively hydrogen oxidation Sodium aqueous solution and dichloropropanol liquid are poured into the T-shaped feed pipe, the reaction temperature is controlled at 80°C, the rotational speed of the rotary filling rotor is 1000r / min, the product discharge time is recorded and the content of epichlorohydrin is sampled and analyzed; 10 minutes After obtaining a stable output product, the mass fraction of epichlorohydrin was analyzed to be 98.2%.

Embodiment 2

[0093] Adopt the equipment of the present invention and Figure 4 The system shown carries out the crude sulfate turpentine desulfurization and refining process, the specific steps and results are as follows:

[0094] Crude sulfate turpentine is continuously fed into the supergravity reaction phase separator-oil phase inlet through the feed pump at a certain stable flow rate, and the hydrogen peroxide that meets the stoichiometric ratio is continuously fed into the supergravity reaction phase separator-water through the feed pump Phase inlet, the two react quickly and fully in the supergravity reaction phase separator 1, the low-valent sulfide impurities are oxidized, and the water obtained from hydrogen peroxide reduction is used as a detergent for oil phase impurities, and the reacted liquid is swirled to avoid rapid and thorough phase separation , the heavy phase is produced as wastewater, and the light phase is turpentine oil containing a small amount of acidic impurities,...

Embodiment 3

[0096] Adopt the equipment of the present invention and image 3 The shown system uses hydroxylamine sulfate aqueous solution and cyclododecanone oxime liquid as raw materials to produce cyclododecanone oxime, and the specific steps and results are as follows:

[0097] In the light phase storage tank, there is an aqueous solution of hydroxylamine sulfate with a mass fraction of 2% (in terms of hydroxylamine), and the pH value is preset to 8 with ammoniacal liquor, and in the heavy phase storage tank, there is cyclododecanone liquid, respectively with 1.5kg / min and 0.5kg / min mass flow rate, put the hydroxylamine sulfate aqueous solution and cyclododecanone liquid into the T-shaped feed pipe, control the reaction temperature at 98 degrees Celsius, and the rotary filling rotor speed is 1000r / min, after 16 minutes at the light phase outlet The cyclododecanone solution of cyclododecanone oxime is produced stably, excess cyclododecanone is removed, the mass fraction of cyclododecan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com