Preparation method of quasi-polyrotaxane film and quasi-polyrotaxane film prepared by same

A quasi-polyrotaxane and thin-film technology, applied in chemical instruments and methods, color-changing fluorescent materials, etc., to achieve the effects of simple operation of equipment, low price, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A preparation method of a photoresponsive pseudopolyrotaxane film (SM1), comprising the following steps:

[0050] (1) Preparation of PCL polymer:

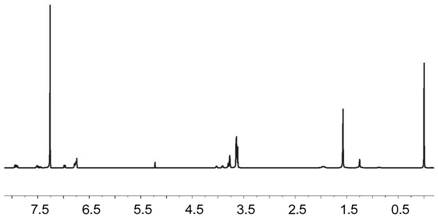

[0051] In a 250mL single-necked round bottom flask, add 0.41mL of benzyl alcohol, 0.2mL of stannous isooctanoate, 22.2mL of ε-CL (ε-caprolactone) and 100mL of dry toluene, and react at 100°C for 12h under the protection of nitrogen. . The solution obtained from the reaction was precipitated in refrigerated methanol, filtered with suction, and dried in vacuum at 30°C for 24 hours to obtain a linear PCL polymer. For its NMR characterization, see image 3 ;

[0052] (2) Preparation of P5-AZO:

[0053] Add 19.2mL of 1,4-dibromobutane, 18.4g of anhydrous potassium carbonate, catalytic amount of potassium iodide and 300mL of acetonitrile into a 500mL three-necked flask, heat to 80°C, and condense to reflux. Dissolve 10.0 g of 4-methoxyphenol in 50 mL of anhydrous acetonitrile, slowly drop it into the above-mentioned three-neck...

Embodiment 2~ Embodiment 11

[0064] The preparation method of the pseudopolyrotaxane film SM2-SM11 listed in table 1, its operating steps are basically the same as in Example 1, the difference is that the host molecule, the guest molecule, the solvent, temperature, host molecule and guest molecule for preparing the quasipolyrotaxane The feed ratio and / or the conditions of the electrostatic spray process are different. The main molecules are pillar aromatic hydrocarbons containing azobenzene and its derivatives, including P5-AZO, P5-AZO 2 、P5-AZO 5 、P5-AZO 10 or P5 2 -AZO; guest molecules include linear PCL and star S-PCL 4 . The specific experimental conditions are shown in Table 1:

[0065] Table 1

[0066]

[0067]

[0068] Among them, the star PCL polymer S-PCL 4 The preparation method is as follows:

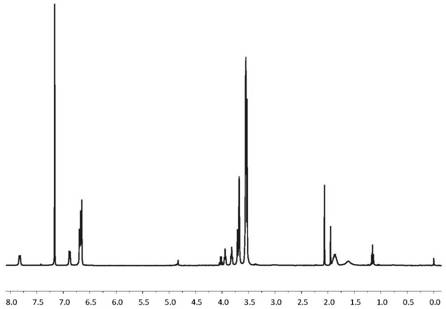

[0069] In a 250mL single-necked round bottom flask, add 0.10mL of pentaerythritol, 0.2mL of stannous isooctanoate, 2.2mL of ε-CL and 100mL of dry toluene, and react at 100°C for 12h under t...

Embodiment 12

[0098] A preparation method of a photoresponsive pseudopolyrotaxane film (SM12), comprising the following steps:

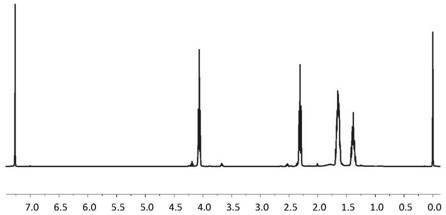

[0099] (1) Preparation of PCL-PEG-PCL:

[0100] In a 250 mL single-necked round bottom flask, add 20.50 g of HO-PEG-OH, 0.2 mL of stannous isooctanoate, 22.83 g of ε-CL and 100 mL of dry toluene. Reacted for 24 h. The reaction solution was added to refrigerated methanol for precipitation, suction filtered, and vacuum-dried at 30°C for 24 h to obtain a triblock copolymer PCL-PEG-PCL, whose structural formula is as follows:

[0101]

[0102] (2) Preparation of PPR12:

[0103] Weigh 10.0 mg of PCL-PEG-PCL, 32.5 mg of P5-AZO and 1 mL of chloroform in a 2 mL sample bottle, and fully dissolve at 30 °C to form a pseudopolyrotaxane PPR12, whose structural formula is as follows Figure 9 shown.

[0104] (3) Preparation of light-controlled quasi-polyrotaxane film SM12:

[0105] Draw 1 mL of quasi-polyrotaxane solution with a syringe, and inject it at a speed of 5 mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com