Large-particle-size waterborne polyurethane emulsion and preparation method thereof, and application of large-particle-size waterborne polyurethane emulsion in impregnated gloves

A water-based polyurethane and emulsion technology, applied in the field of polyurethane emulsion, can solve the problems of increased difficulty in flocculation and solidification, increased resin instability, poor wear resistance and hydrolysis resistance, etc., to reduce environmental pollution and waste of water sources, and reduce micro The degree of phase separation, the effect of simple and fast preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

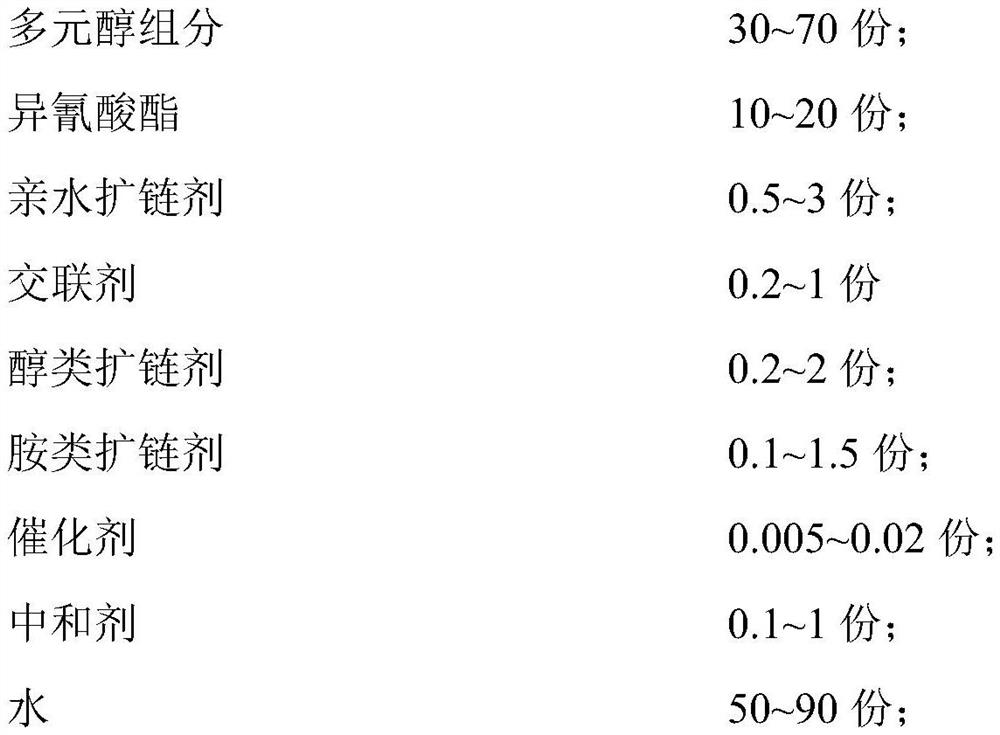

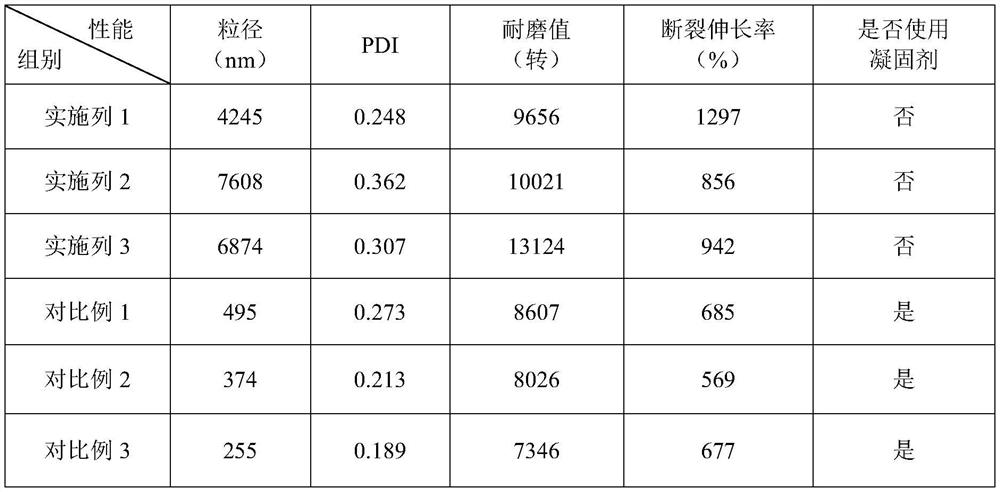

[0044] The large particle size aqueous polyurethane emulsion provided by this embodiment is prepared by the following method:

[0045] Mix 30 parts of polypropylene glycol (number average molecular weight 2000) and 10 parts polyether triol (number average molecular weight 3000), under nitrogen protection, after dehydration at 120°C for 4 hours, add 10 parts of hexamethyl diisocyanate and react at 90°C 1h, add 0.4 parts of dihydroxypropionic acid, add 0.2 parts of dimethylolpropionic acid, 0.3 parts of trimethylolpropane and 0.3 parts of methylpropanediol after reacting at 80°C for 1h, add 0.01 parts of isooctanoic acid after reacting at 80°C for 1h Bismuth and 1 part of acetone, continue to react for 1 hour, lower the temperature to 50°C, add 20 parts of acetone and stir evenly, add 0.5 parts of triethylamine to neutralize, stir for 10 minutes, add 70 parts of deionized water to emulsify, and then dropwise add 0.1 part of diethylene triethylamine Amines are used for chain exte...

Embodiment 2

[0047] The large particle size aqueous polyurethane emulsion provided by this embodiment is prepared by the following method:

[0048] After dehydrating 20 parts of polytetrahydrofuran ether diol (number average molecular weight 2000) and 15 parts polyether triol (number average molecular weight 3000) at 120°C, add 12 parts of toluene diisocyanate to react at 80°C for 1 hour, first add 0.6 parts of diisocyanate Methylol propionic acid reacted at 80°C for 1 hour, then added 0.2 parts of dimethylol propionic acid, 0.3 parts of 1,2,6-hexanetriol and 0.3 parts of methylpropanediol, reacted at 75°C for 1 hour, then added 0.01 part of zinc isooctanoate and 1 part of acetone, continue to react for 1 hour, lower the temperature to 50°C, add 20 parts of acetone and stir evenly, add 0.5 parts of sodium hydroxide to neutralize, stir for 10 minutes, add 65 parts of deionized water to emulsify, add dropwise 0.2 parts of hydroxymethylethylene di Amines are used for chain extension, and fina...

Embodiment 3

[0050] The large particle size aqueous polyurethane emulsion provided by this embodiment is prepared by the following method:

[0051] Mix 25 parts of polycaprolactone triol (number average molecular weight 3000) and 13 parts of polypropylene glycol (number average molecular weight 3000) and dehydrate at 120°C, add 8 parts of isophorone diisocyanate and 5 parts of p-phenylene diisocyanate React at 85°C for 1 hour, add 0.3 parts of dihydroxybutyric acid, add 0.2 parts of dimethylolpropionic acid, 0.3 parts of trimethylolpropane and 0.3 parts of 1,4-butanediol after reacting for 1 hour, and react at 80°C for 1 hour Add 0.01 part of bismuth isooctanoate and 1 part of acetone, continue the reaction for 1 hour, cool down to 50°C, add 20 parts of acetone and stir evenly, add 0.5 part of triethylamine to neutralize, stir for 10 minutes, add 70 parts of deionized water to emulsify, add dropwise 0.1 part Diethylenetriamine and 0.1 part of hydroxymethylethylenediamine are chain extended...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com