Inorganic-organic core-shell framework loaded low-dose precious metal palladium material and preparation thereof and application in electro-catalytic dechlorination hydrogenation reaction

A low-dose, precious metal technology, applied in electrolytic organic production, electrodes, electrolysis process, etc., can solve the problems of thermodynamic instability of precious metal nanoparticles, reducing effective reactive sites, reducing reaction efficiency, etc., to achieve high activity per unit mass, Atomic economy, the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

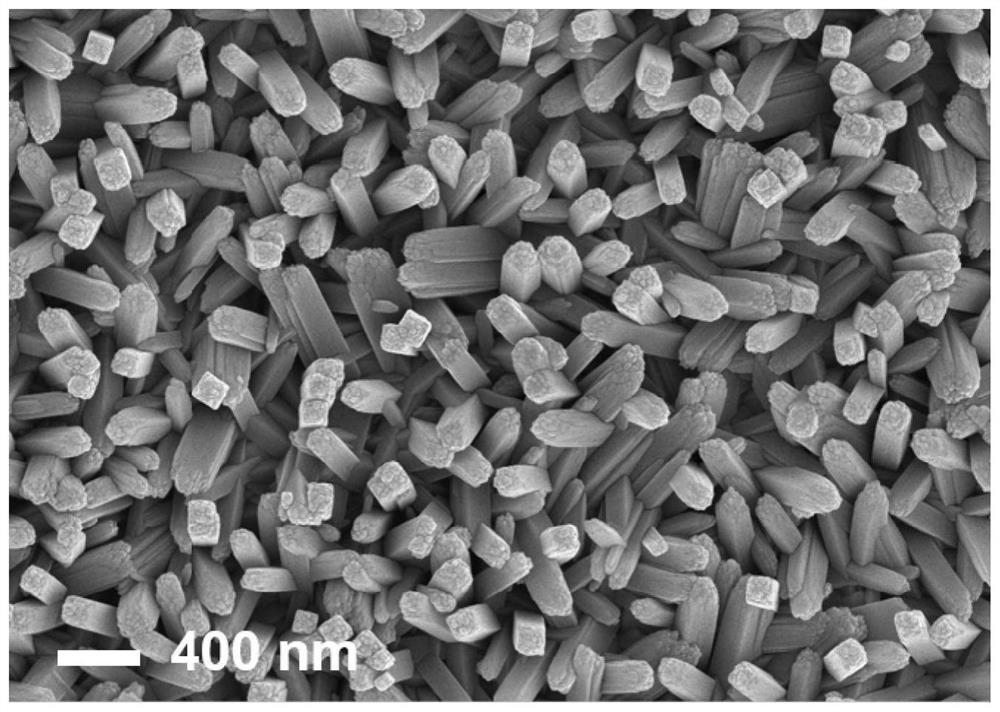

[0035] 1. Preparation of TiO with nano-array structure 2 vertical nanorods. Immerse the FTO conductive glass into the hydrochloric acid aqueous solution of tetrabutyl titanate (the content of tetrabutyl titanate is 2.8%, and the solvent is 37wt% hydrochloric acid aqueous solution), react with hydrothermal reaction at a constant temperature of 150°C for 5 hours, then wash it, and keep it in the air at a constant temperature of 450°C. Calcined for 3h to prepare FTO / TiO 2 Material. figure 2 For FTO / TiO 2 From the SEM image, it can be seen that TiO 2 It has a one-dimensional nanorod array structure and grows vertically on the surface of FTO. The average diameter of the nanorods is about 160nm.

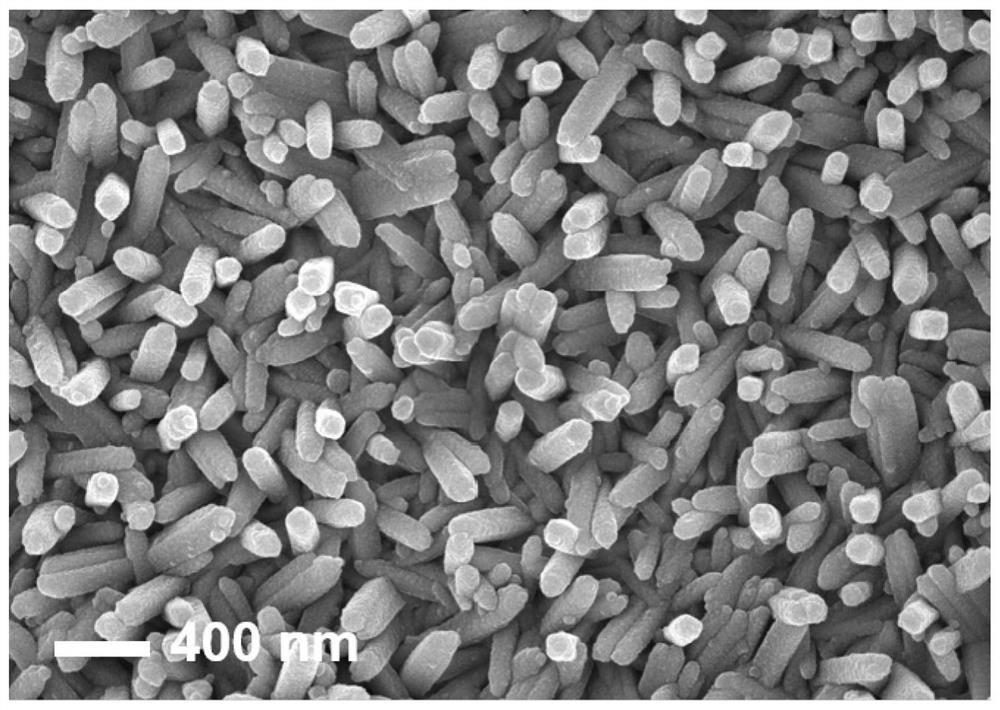

[0036] 2. FTO / TiO 2 Preparation of @PDA. The above FTO / TiO 2 placed vertically containing 1.21g L -1Tris-HCl and 0.5gL -1 In the dopamine solution, stir at a constant temperature of 15°C for 12 hours, then wash with deionized water, and dry to obtain FTO / TiO 2 @PDA. image 3 In...

Embodiment 2

[0043] 1. FTO / TiO 2 Preparation of Vertical Nanorods. The preparation method and process are the same as in Example 1, and TiO with an array structure is vertically grown on the FTO surface. 2 One-dimensional nanorods.

[0044] 2. FTO / TiO 2 Preparation of @PDA. The preparation method and process are the same as in Example 1, except that the concentration of dopamine is 1.0 g L -1 , the resulting FTO / TiO 2 The thickness of the polydopamine thin layer of the one-dimensional nanorod is 12.15 nm, which is higher than 5.23 nm in Example 1.

[0045] 3. FTO / TiO 2 Preparation of @PDA / Pd. The preparation method and process are the same as in Example 1, except that the carrier adopts FTO / TiO with a polydopamine layer thickness of 12.15nm 2 @PDA, the resulting FTO / TiO 2 The particle size of palladium nanoparticles on @PDA / Pd is about 2.0nm, and the loading of Pd is calculated to be 0.60%.

[0046] 4. With FTO / TiO 2 The @PDA / Pd material is used as the cathode for electrocatalyt...

Embodiment 3

[0048] 1. Preparation of cathode materials. The preparation method and process are the same as in Example 1, and the results obtained are the same as in Example 1.

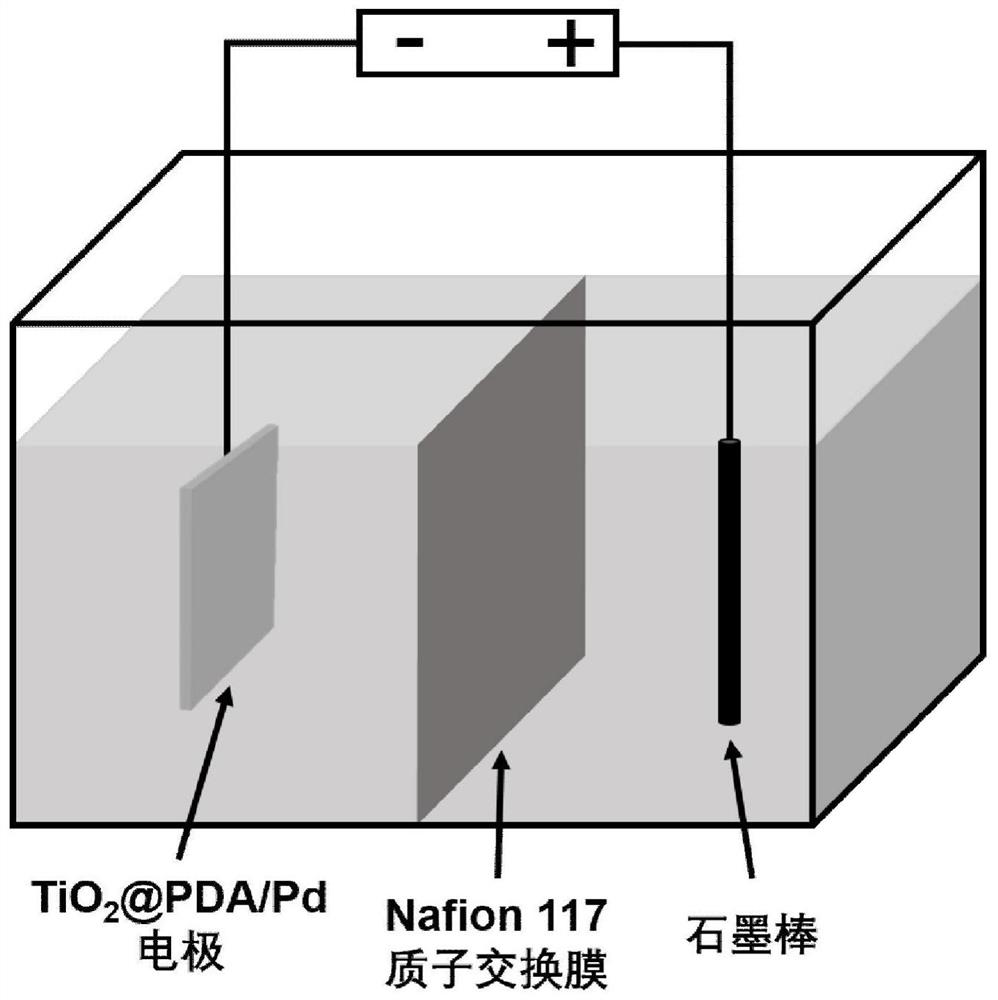

[0049] 2. With FTO / TiO 2 The @PDA / Pd material is used as the cathode for electrocatalytic dechlorination and hydrogenation of 3,6-dichloropicolinic acid. H-type electrode reaction tank is used, N117 cationic membrane is used to separate the cathode and anode electrolyte, the anode is made of graphite rod material, and the cathode is made of FTO / TiO prepared above. 2 @PDA / Pd material. The electrolyte in the anode reaction tank is sodium hydroxide buffer solution (pH=10); the catholyte is 1mmol L -1 3,6-dichloropicolinic acid solution, adjust its pH to 10.0 with sodium hydroxide buffer. The electrolyte was kept at 30°C in a water bath, and the electrolysis current was controlled at 5.0mA cm -2 , electrolyzed for 4 hours under constant stirring.

[0050] The high-performance liquid chromatography is used for d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com