Catalyst for catalytic oxidation of VOCs and preparation method of catalyst

A catalytic oxidation and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of difficult process control, difficult industrialization, etc. The effect of short cycle, easy availability of raw materials and economical raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A catalyst for the catalytic oxidation of VOCs, the active component of which includes a composite oxide of copper and manganese, and the main phase is Cu 1.5 mn 1.5 o 4 .

[0052] The specific surface area of the catalyst is 230m 2 / g, the pore volume is 0.42cm 3 / g, the average pore diameter is 6.8nm.

[0053] Its preparation method comprises the following steps:

[0054] (1) Anhydrous copper acetate and manganese acetate with a molar ratio of copper and manganese of 1:2 are dissolved in a mixed solution of ethylene glycol and ethanol with a molar ratio of 1:3 to obtain solution A, and oxalic acid and used anhydrous copper acetate Oxalic acid with a molar ratio of 1:1.2 to manganese acetate is dissolved in another ethylene glycol and ethanol solution with a molar ratio of 1:3 to obtain solution B. Pour solution B into vigorously stirred solution A at room temperature and react at room temperature for 0.5 h, separating the generated sol-gel and drying at 80°C t...

Embodiment 2

[0060] Example 2 is basically the same as Example 1, except that in step (2), the solid obtained in step (1) is calcined at 400° C. to obtain a catalyst. The specific surface area is 208m 2 / g, the pore volume is 0.35cm 3 / g, the average pore diameter is 6.4nm.

Embodiment 3

[0062] Example 3 is basically the same as Example 1, except that in step (2), the solid obtained in step (1) is calcined at 450° C. to obtain a catalyst. The specific surface area is 158m 2 / g, the pore volume is 0.38cm 3 / g, the average pore diameter is 7.5nm.

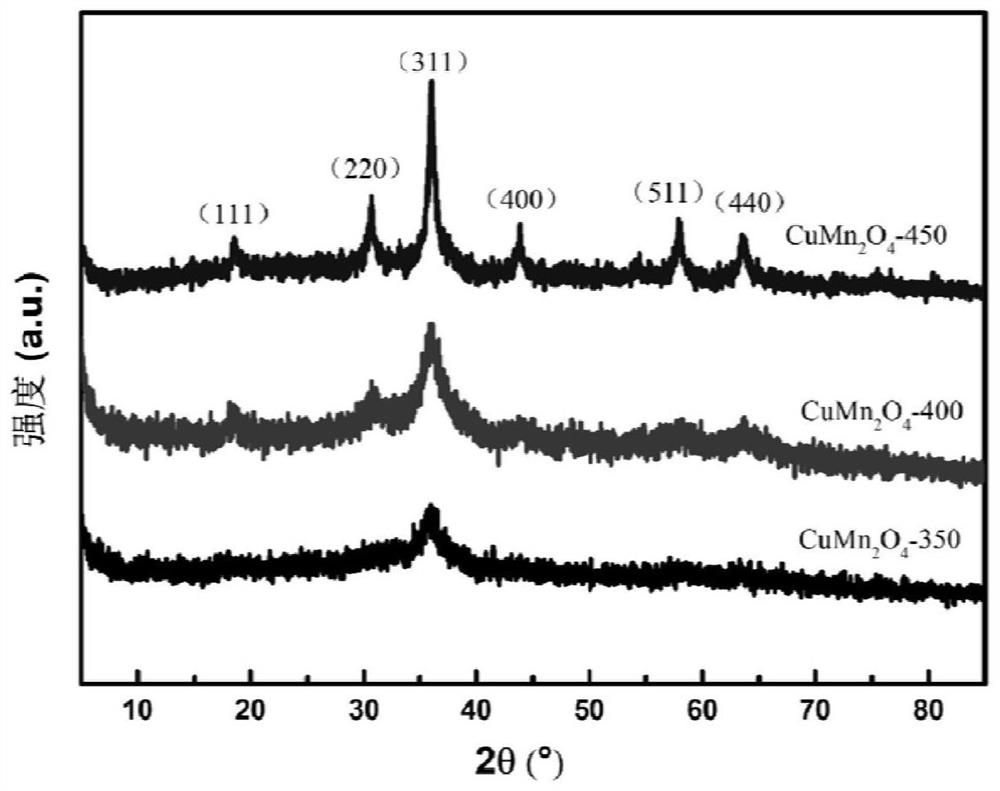

[0063] Depend on figure 1 It can be seen that the main phase of the copper-manganese catalysts prepared at different temperatures in Examples 1, 2, and 3 is Cu 1.5 mn 1.5 o 4 , as the calcination temperature increases, the crystallinity increases and grains grow at high temperature. The low crystallinity is conducive to the generation of defects, thereby improving the ability of the catalyst to absorb oxygen.

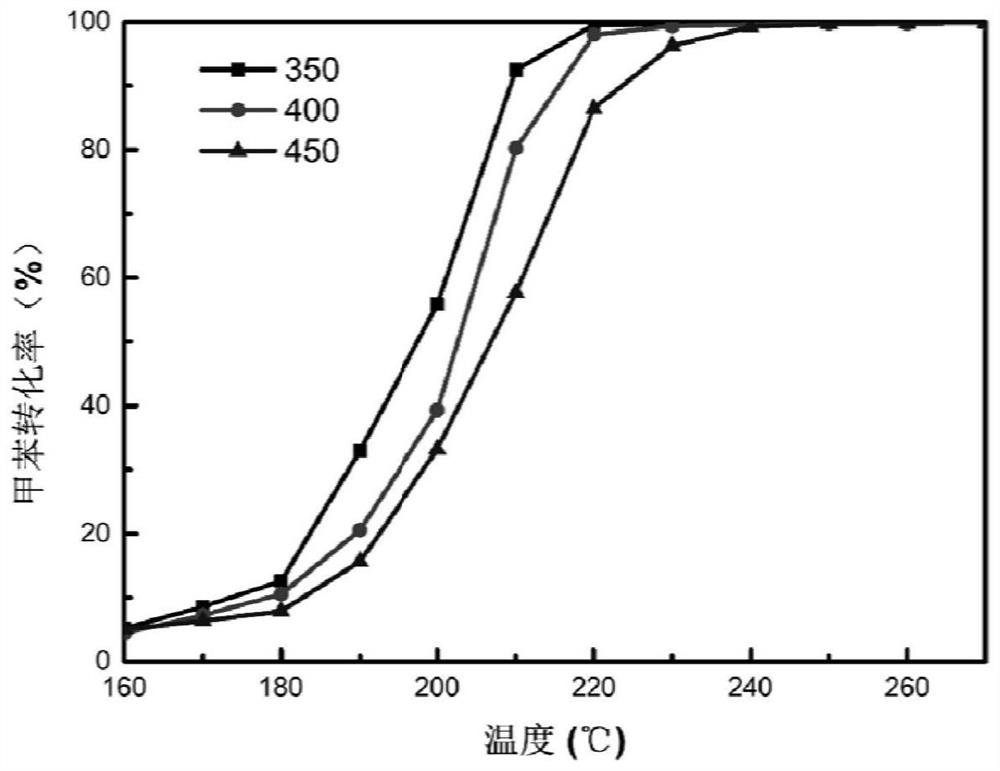

[0064] Catalytic activity test: toluene concentration 1000ppm, gas space velocity 20000mlg -1 h -1 . Gas chromatography FID detects the concentration of toluene, and TCD detects the reaction tail gas CO 2 and CO. The obtained 350°C pyrolysis catalyst has a temperature of 100% conversion of toluene at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com