Method for rapidly detecting content of cyanide in baijiu brewing fermented grains

A detection method and cyanide technology, applied in the field of liquor analysis and detection, can solve the problems of difficult pre-treatment, difficult to popularize and apply, and high requirements for instruments and equipment, so as to overcome pH interference and color interference, and avoid distillation pre-treatment procedures, instruments and equipment less demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

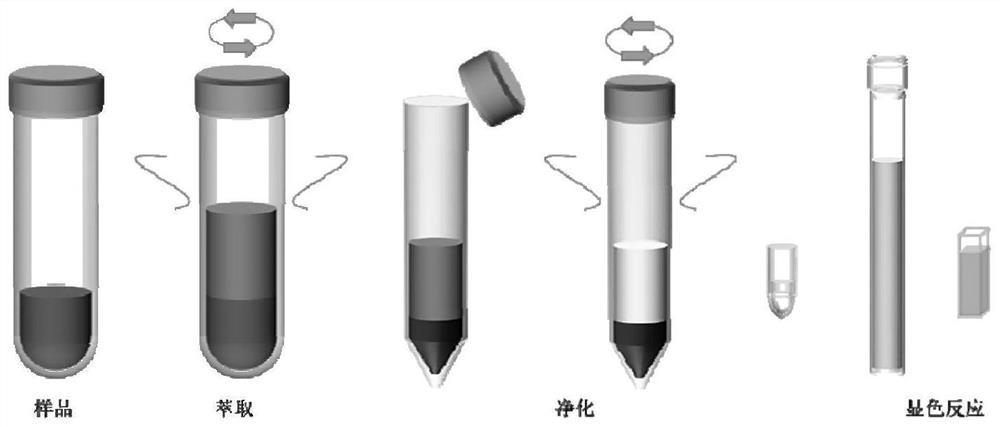

[0045] Embodiment 1 The method of using QuEChERS pretreatment technology to process liquor fermented grains sample

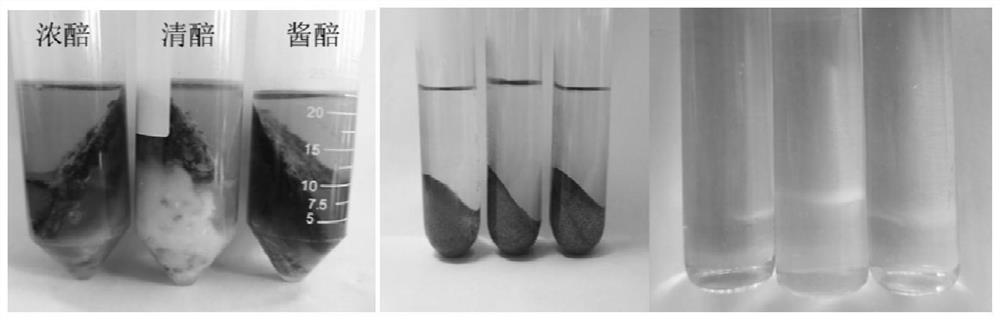

[0046] Accurately weigh 3 g of wine grains (respectively, Luzhou-flavor wine grains, Qing-flavor wine grains, and Maotai-flavor wine grains) into a 50 mL plastic centrifuge tube, add 7.5 mL of phosphate buffer (pH=9.0) and vortex to mix, soak for 15 minutes, Add 10mL acetonitrile, sonicate for 10min, freeze at -20°C for 8min, put a ceramic homogeneous ion, add 4.0g MgSO 4 , 1.0g NaCl, shake and vortex immediately for 1min, then centrifuge at 5000r / min for 5min, draw (6mL) the supernatant until it contains 750mg MgSO 4 , 120mg C 18 , 120mg NH 2 , 20mg GCB in a 15mL plastic centrifuge tube, vortex for 1min, centrifuge at 5000r / min for 5min, pipette 1mL supernatant into a 5mL EP tube, blow with nitrogen until nearly dry, add 5mL 2g / L NaOH for colorimetric and spectroscopic analysis.

Embodiment 2

[0047] Embodiment 2 The method of using QuEChERS pretreatment technology to process liquor fermented grains sample

[0048] Accurately weigh 6g of fermented grains into a 50mL plastic centrifuge tube, add 15mL of phosphate buffer (pH=8.5) and vortex to mix, soak for 30min, add 20mL of acetonitrile, ultrasonicate for 15min, freeze at -20°C for 8min, put a ceramic Homogeneous, add 8.0gMgSO 4 , 2g NaCl, shake and vortex immediately for 1min, then centrifuge at 5000r / min for 5min, draw (10mL) the supernatant until it contains 1250mg MgSO 4 , 200mg C 18 , 200mg NH 2 , 33mg GCB in a 15mL plastic centrifuge tube, vortex for 1min, centrifuge at 5000r / min for 5min, pipette 1mL supernatant into a 5mL EP tube, blow with nitrogen until nearly dry, add 5mL 2g / L NaOH for colorimetric and spectroscopic analysis.

Embodiment 3

[0050] A method for detecting cyanide content in liquor fermented grains. Using the QuEChERS pretreatment technology to process the liquor fermented grains sample, the isonicotinic acid-barbituric acid spectrophotometric method is used for detection. The specific steps of the method include the following steps:

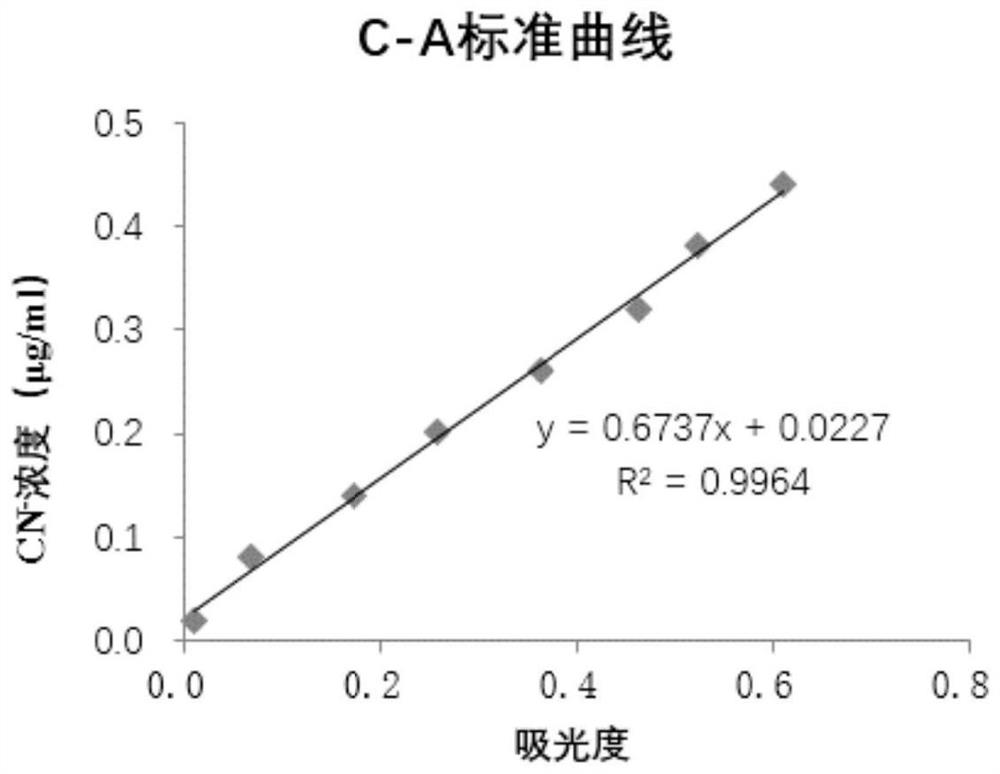

[0051] (1) Solution preparation: Use GBW(E)080115, the standard material for cyanide component analysis in water, to prepare cyanide ion standard intermediate solution (1μg / mL); sodium hydroxide solution (2g / L, 20g / L); phenolphthalein solution (10g / mL); L); Acetic acid solution (1+24): Mix acetic acid and water at a volume ratio of 1:24; Chloramine T solution (10g / L): Dissolve 1g of Chloramine T in water and dilute to 100mL. Prepare just before use; phosphate buffer (0.5M, pH=7.0), phosphate buffer (0.2M, pH=8.5-9.0); isonicotinic acid-barbituric acid reagent: weigh 2.5g of isonicotinic acid ( C 5 h 5 o 2 N) and 1.25g barbituric acid (C 4 h 4 N 2 o 3 ), add to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com