Ni-Fe hydrotalcite biochar composite catalyst and preparation method and application thereof

A technology of composite catalyst and biochar, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of limited application, achieve good specific surface area, excellent The effect of processing efficiency and preparation method is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of Ni-Fe hydrotalcite biochar composite catalyst, comprising the steps of:

[0034] (1) High-temperature carbonization and pyrolysis of agricultural biomass under a protective atmosphere to produce biochar;

[0035] (2) Dispersing the biochar in water to prepare a biochar dispersion, then adding nickel nitrate, ferric nitrate, sodium fluoride and urea to the dispersion and stirring to obtain a suspension;

[0036] (3) The Ni-Fe hydrotalcite biochar composite catalyst was prepared after the suspension was hydrothermally reacted.

[0037] Further, the agricultural biomass is one of peanut hulls, straw, and ramie.

[0038] Further, the particle size of the agricultural biomass is 30-50 mesh;

[0039] Preferably, the particle size of the agricultural biomass is 40-50 mesh.

[0040] Furthermore, the heating rate of high-temperature carbonization and pyrolysis is 5-10°C / min, the pyrolysis temperature is 300-700°C, and the pyrolysis time is 2-4 hours; ...

Embodiment 1

[0056] A kind of Ni-Fe hydrotalcite biochar composite catalyst, is made by following steps:

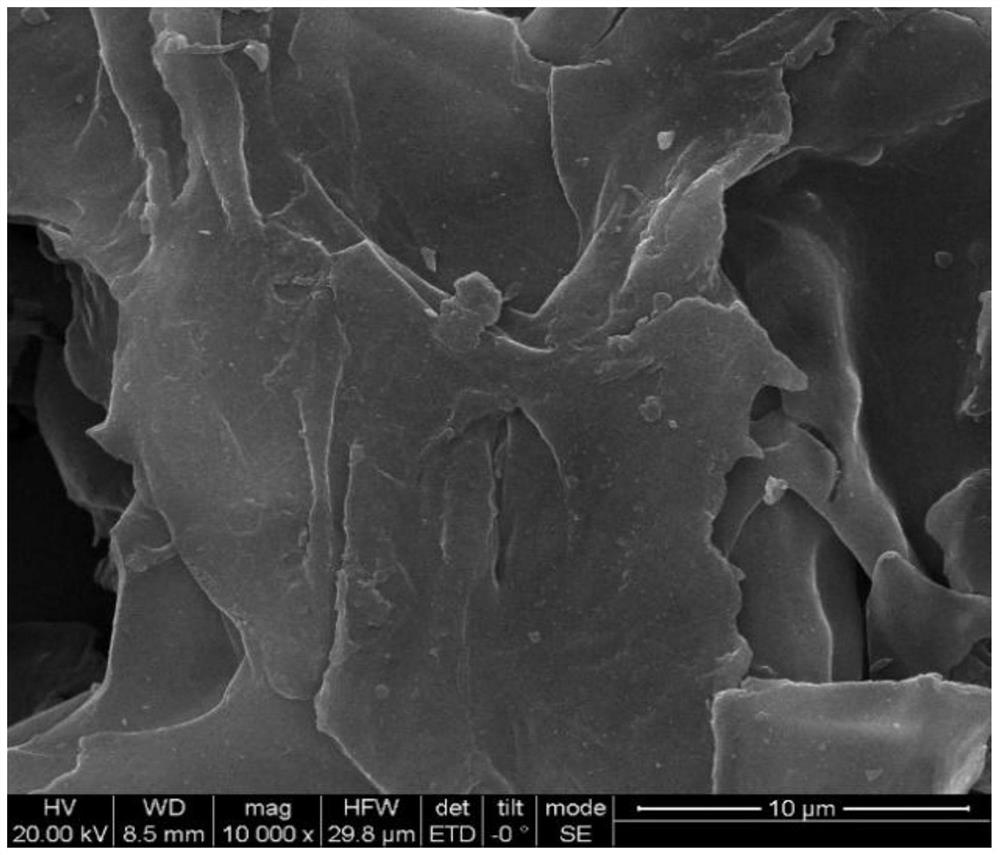

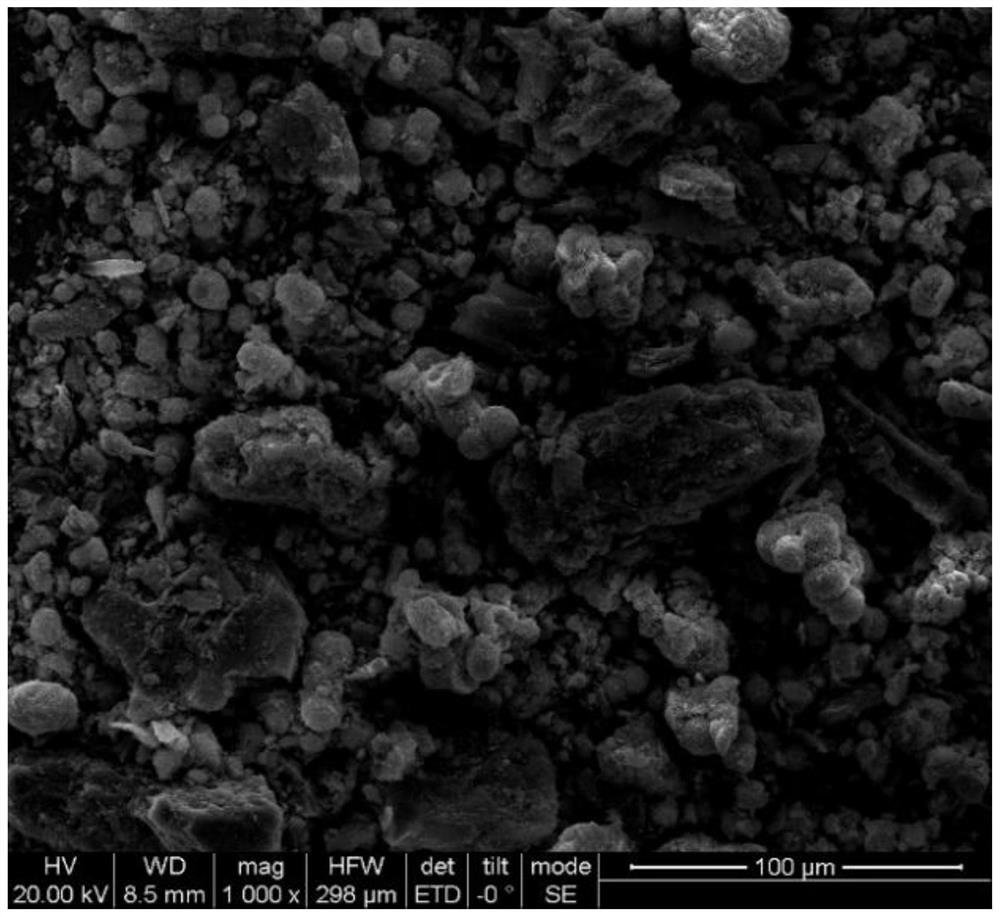

[0057] (1) Use peanut shells that have been naturally air-dried and ground through a 40-mesh sieve as raw materials, and place them in a tube furnace with an initial temperature of 25°C, and heat up at a rate of 5°C / min under nitrogen until the temperature reaches After 600°C, high-temperature carbonization pyrolysis was carried out, and peanut shell biochar was obtained after pyrolysis for 4 hours. The scanning electron microscope image of peanut shell biochar is as follows figure 1 shown;

[0058] (2) Disperse 1 g of biochar in 70 mL of water to prepare a biochar dispersion, and then add 5.816 g of nickel nitrate hexahydrate, 4.040 g of ferric nitrate nonahydrate, 0.925 g of sodium fluoride and 6.006 g of urea to the dispersion Stir for 40min, then wash the beaker with 10mL, and pour the washing liquid into the above stirring system to obtain a suspension;

[0059] (3) The obtaine...

Embodiment 2

[0062] A kind of Ni-Fe hydrotalcite biochar composite catalyst, is made by following steps:

[0063] (1) Using ramie that has been naturally air-dried and ground through a 50-mesh sieve as the raw material, it is placed in a tube furnace with an initial temperature of 25 °C, and the temperature is raised at a rate of 7 °C / min under nitrogen conditions, and the temperature reaches 700 °C. After ℃, carry out high-temperature carbonization and pyrolysis, and obtain ramie biochar after pyrolysis for 2 hours;

[0064] (2) Disperse 0.5g of biochar in 80mL of water to prepare a biochar dispersion, and then add 4.653g of nickel nitrate hexahydrate, 3.232g of ferric nitrate nonahydrate, 0.525g of sodium fluoride and 4.800g of urea to the dispersion After stirring for 50min to obtain a suspension;

[0065] (3) The obtained suspension was hydrothermally reacted at 120° C. for 18 h, and the reaction product was dried at 70° C. for 20 h to prepare a Ni-Fe hydrotalcite biochar composite ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com