Phosphate oxygen isotope pretreatment sample preparation method for characteristic water sample of phosphogypsum leachate

An oxygen isotope and leachate technology, which is applied in the preparation, sampling, and measuring devices of test samples, can solve the problems of low phosphate recovery rate, high cost, time-consuming and labor-intensive, etc., to improve purity, save time and Cost, the effect of eliminating the suction filtration step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

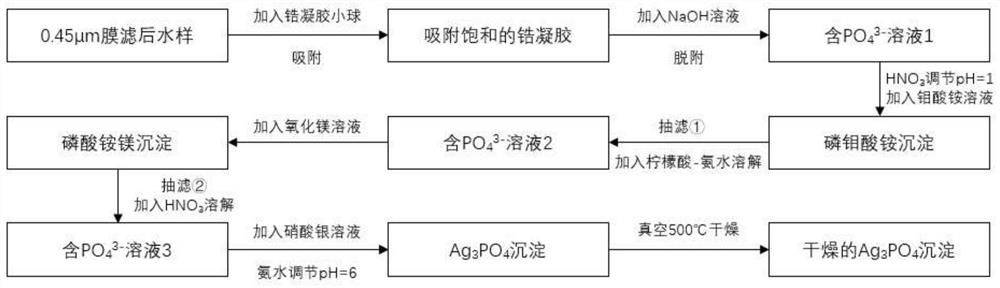

Method used

Image

Examples

Embodiment 1

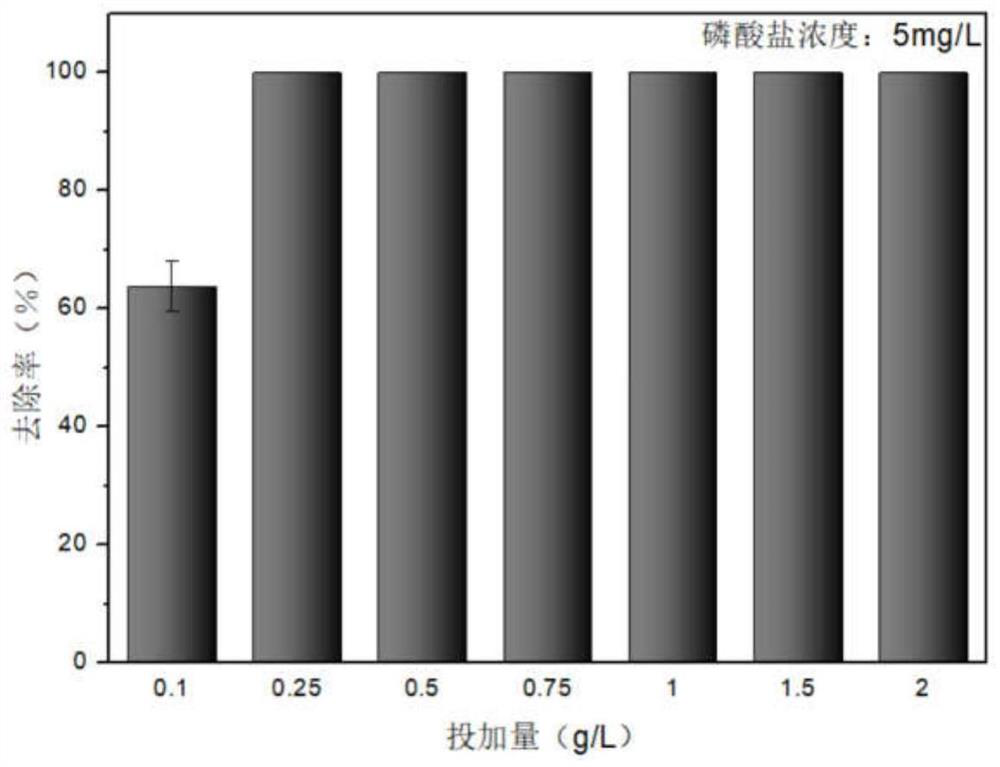

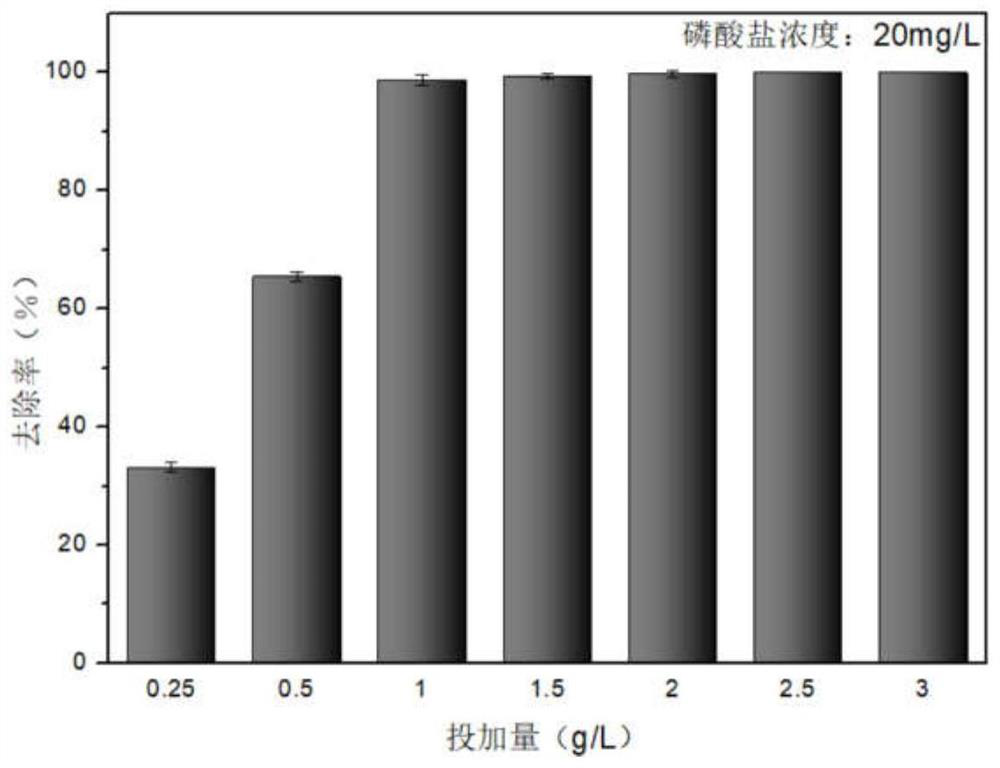

[0052] The method of the present invention analyzes the phosphate oxygen isotope of simulated phosphorus-containing wastewater and simulated phosphorus-containing wastewater with the characteristics of phosphogypsum leachate:

[0053] According to the water quality analysis results of phosphogypsum leachate, a group of phosphorus-containing wastewater with different concentration gradients were prepared, respectively 5mg / L, 20mg / L, 50mg / L, 100mg / L and 300mg / L, using potassium dihydrogen phosphate and ultrapure water Configure, and configure a group of phosphorus-containing wastewater with the same phosphorus concentration gradient in addition, so that the fluoride ion concentration of the latter is 100mg / L, the sulfate radical concentration is 2500mg / L, and the organic matter concentration is 40mg / L. Use sodium fluoride, Potassium sulfate and humic acid configuration. The configuration volumes are 1200, 500, 280, 200 and 80 ml respectively, and the phosphate oxygen isotope pre...

Embodiment 2

[0060] The inventive method is to the analysis of actual phosphogypsum leachate and phosphogypsum stockpile groundwater:

[0061] Two parallel samples were taken from the leachate collection tank and groundwater of a phosphogypsum storage yard, the former were marked as 1#-1 and 1#-2, and the latter were marked as 2#-1 and 2#-2. Immediately after sampling, use 0.45 μm membrane filter to remove particulate matter, carry out δ by the method of the present invention 18 o P Analytical pretreatment experiments.

[0062] Table 2 The recovery rate of phosphate in each step of the actual site water sample pretreatment

[0063]

[0064] Table 2 shows that the recovery rate of phosphate in each step of the present invention applied to actual phosphogypsum leachate and groundwater of phosphogypsum stockpile is good, and the recovery rate of phosphate to finally generate silver phosphate reaches more than 90%.

[0065] Figure 6 is the phosphate oxygen isotope test results of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com