Metal oxide-perovskite interface treatment method and battery

A treatment method and oxide technology, which is applied in the field of solar cells, can solve the problems of complex process, difficult to meet large-scale promotion and application, and high cost, and achieve the effect of improving device stability and photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

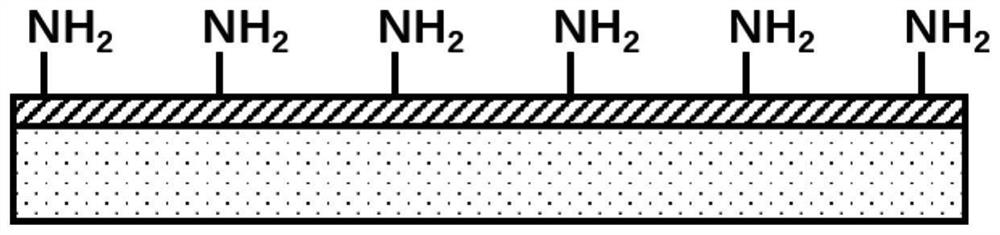

[0066] In the present invention, the preparation method of the battery preferably includes:

[0067] Drying the substrate after cleaning;

[0068] preparing a metal oxide film on the dried substrate surface;

[0069] Soaking the metal oxide film in a silane solution after plasma treatment;

[0070] Drying and heat-treating the soaked metal oxide film;

[0071] Preparing a perovskite film on the surface of the heat-treated metal oxide film;

[0072] An electron transport layer and / or a hole transport layer are prepared on the surface of the perovskite thin film.

[0073] In the present invention, the cleaning method preferably includes:

[0074] Wash with ethanol, isopropanol and acetone in sequence.

[0075] In the present invention, the cleaning time is preferably 20-40 minutes, more preferably 25-35 minutes, and most preferably 30 minutes.

[0076] In the present invention, the drying method is preferably blowing with a nitrogen gun.

[0077] In the present invention,...

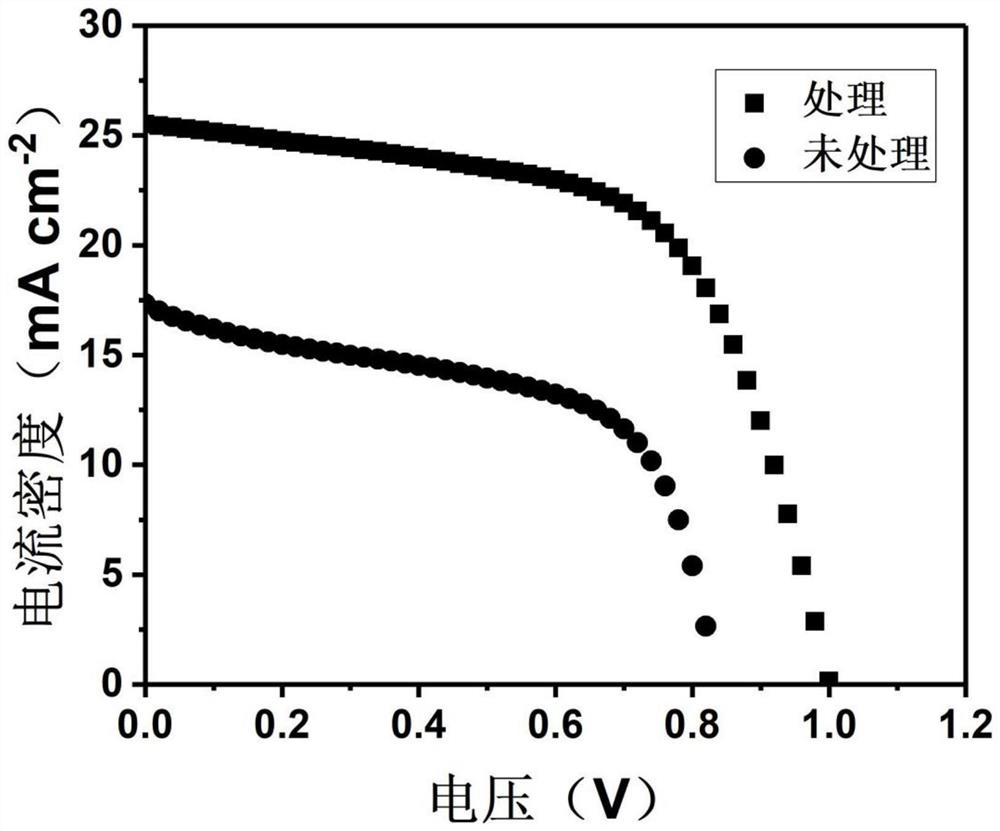

Embodiment 1

[0126] Wash 4*4cm FTO film (glass thickness 2mm, FTO film thickness 100nm) glass with ethanol, isopropanol (IPA) and acetone for 30 minutes respectively, and blow dry with nitrogen gun.

[0127] A layer of dense NiO was sputtered on the surface of FTO thin film glass by magnetron sputtering x Thin film (thickness 20nm, x≤1), sputtering power is 80W, 30min.

[0128] The above-sputtered film was treated with oxygen plasma for 10 min at a power of 2 kW.

[0129] 10 μL of acetic acid, 1 mg of 3-aminopropyltrimethoxysilane and 100 mL of deionized water were mixed together and stirred for 30 minutes to form a homogeneous solution.

[0130] The film after the above oxygen plasma treatment was vertically or NiO x Put it face up in the above-prepared solution, soak at room temperature (26°C) for 70min; then rinse off the surface liquid with deionized water and dry it with a nitrogen gun; then place the substrate on a hot stage at 80°C for 60min.

[0131] Weigh 600mg lead iodide (PbI...

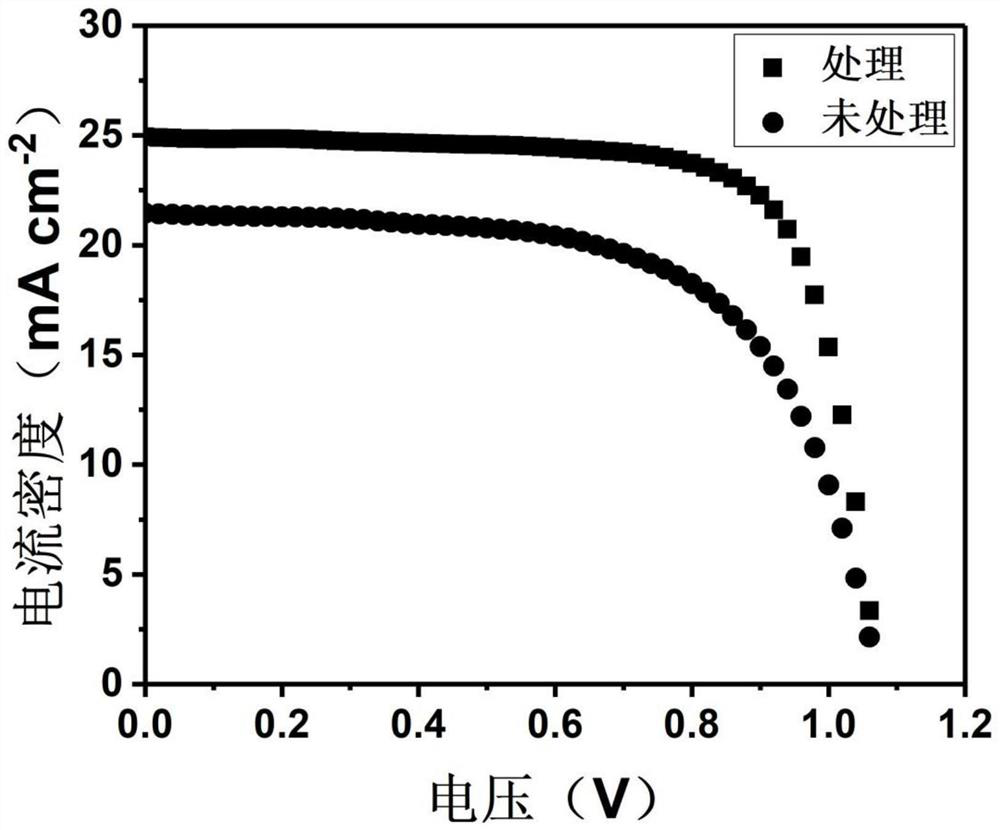

Embodiment 2

[0136] Wash 1.5*1.5cm indium tin oxide (ITO) (glass thickness 2mm, ITO film thickness 150nm) glass with ethanol, isopropanol (IPA) and acetone for 30 minutes respectively, and blow dry with nitrogen gun.

[0137] Tin dioxide (SnO 2 ) stock solution and ultrapure water according to the volume ratio of 1:5 diluted, fully stirred to obtain SnO 2 Precursor solution; take 50 μL SnO 2 The precursor solution was evenly spread on the surface of the ITO conductive glass, and the parameters of the homogenizer were set to 4000rpm / s, and the time was 30s; then placed on a hot stage at 150°C for 30min to obtain SnO 2 Thin film (30nm).

[0138] The above-prepared SnO 2 The film was treated for 30 minutes in an ultraviolet ozone cleaner (Shanghai Cairong Economic and Trade Development Co., Ltd., UV-O3 / 70N) for subsequent spin coating.

[0139] 10 μL of acetic acid, 0.5 mg of 3-aminopropyltrimethoxysilane and 100 mL of deionized water were mixed together and stirred for 30 minutes to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com