Flexible lead-free X-ray protection material as well as preparation method and application thereof

A protective material and X-ray technology, applied in the field of flexible lead-free X-ray protective material and its preparation and application, can solve the problems of high Shore hardness, high Shore hardness of gloves, poor mechanical properties, etc., and reach the mixing temperature Appropriate, good protective performance, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

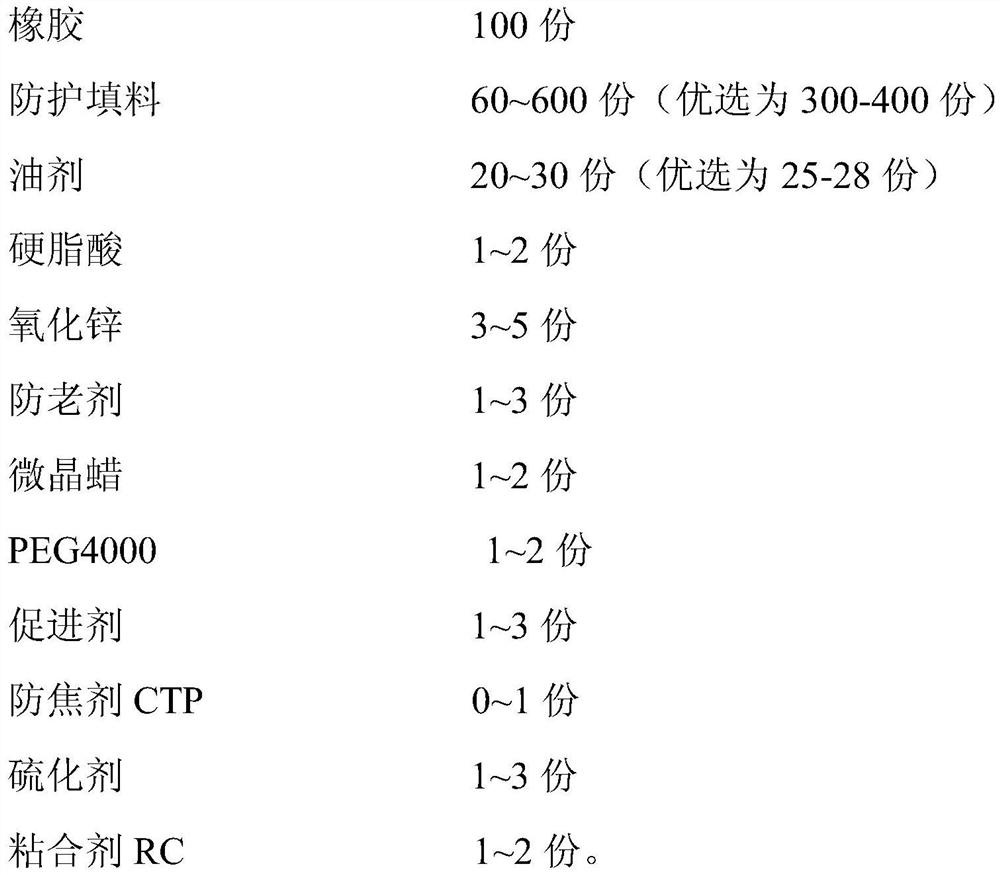

[0038] The flexible lead-free X-ray protective material in this embodiment consists of the following raw materials in parts by mass:

[0039]

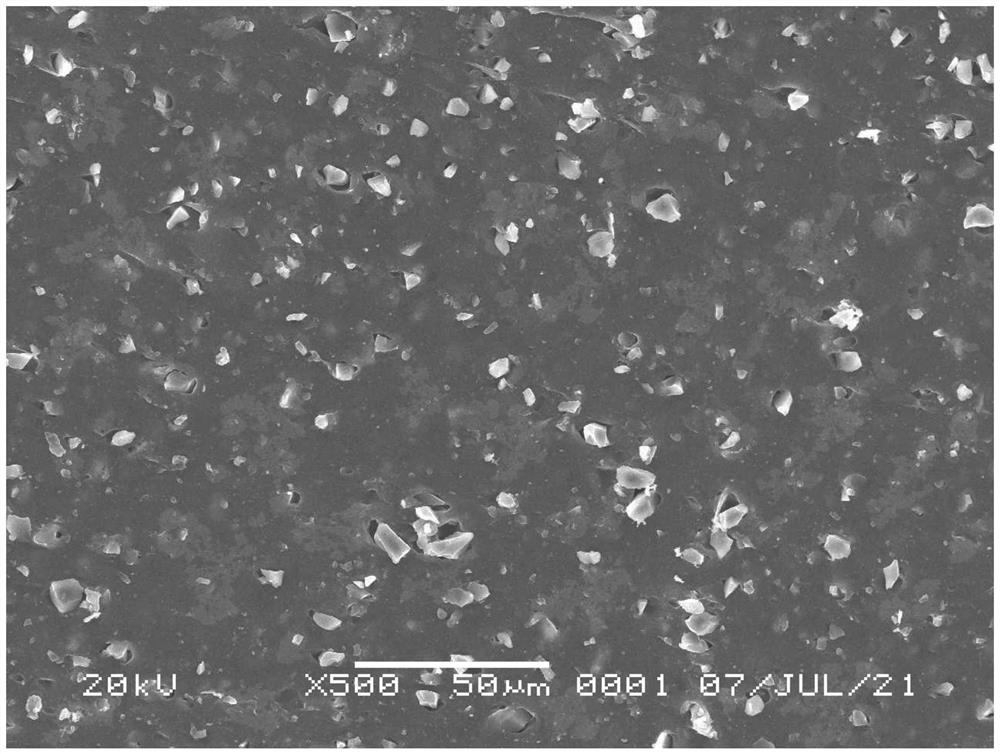

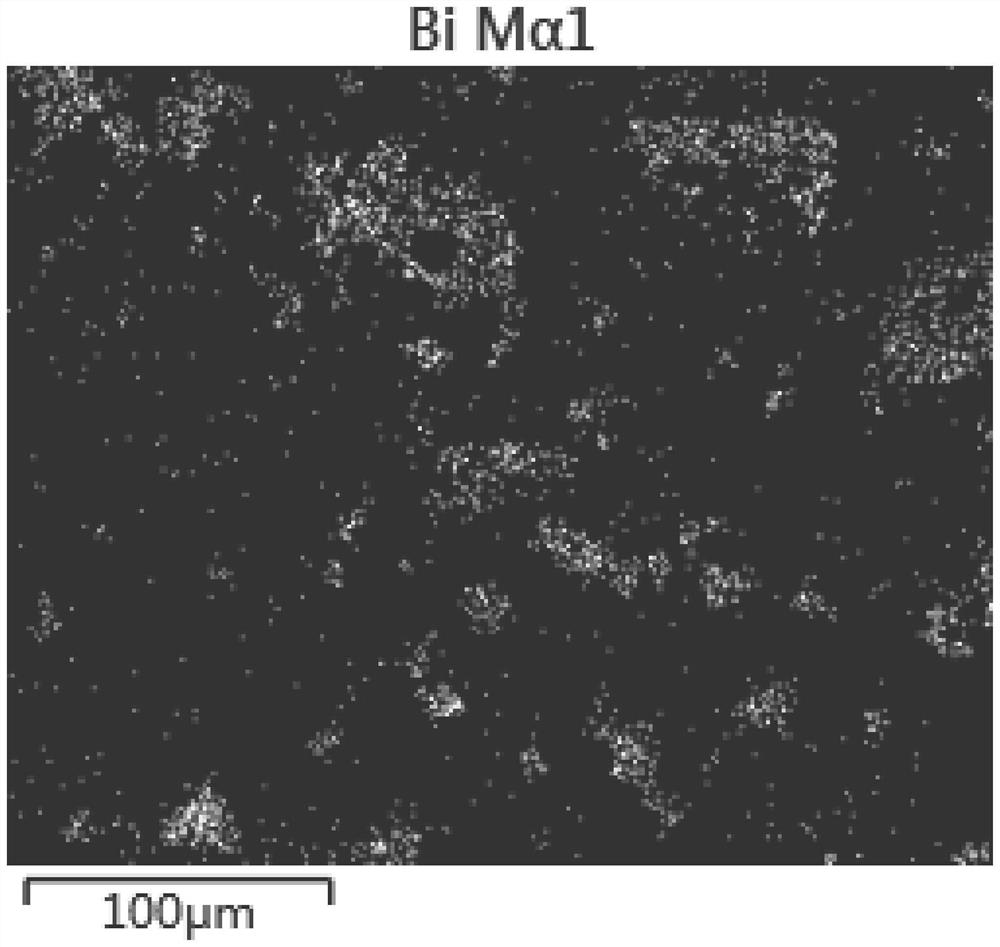

[0040] In this embodiment, the radiation protection filler is nano-scale bismuth oxide powder, which accounts for about 74% of the total raw material mass.

[0041] Its preparation method is:

[0042] S1 masticating: Weigh the natural rubber with the formula amount, masticate in the internal mixer, the masticating temperature is 50°C, and the masticating time is 5min;

[0043] S2 One-step mixing: After the raw rubber is masticated, add active agent, anti-aging agent MB, and processing aids for mixing. The mixing temperature is 80°C, and the mixing time is 3 minutes;

[0044] S3 secondary mixing: After S2 is completed, add protective filler, naphthenic oil, plasticizer to the internal mixer, and continue mixing; mixing temperature is 80°C, mixing time is 3.5min; then transfer to open mixing The left and right cutters in the machine...

Embodiment 2

[0048] The flexible lead-free X-ray protective material in this embodiment consists of the following raw materials in parts by mass:

[0049]

[0050]

[0051] In this embodiment, the radiation protection filler is nano-scale bismuth oxide powder, which accounts for about 68% of the total raw material mass.

[0052] Its preparation method is:

[0053] S1 mastication: Weigh the rubber with the formula amount, masticate it in the internal mixer, the mastication temperature is 60°C, and the mastication time is 5min;

[0054] S2 one-step mixing: After the raw rubber is masticated, add active agent, anti-aging agent MB, and processing aids for mixing. The mixing temperature is 70°C, and the mixing time is 3 minutes;

[0055] S3 secondary mixing: After S2 is completed, add protective filler, hydroxy silicone oil, and plasticizer to the internal mixer, and continue mixing; the mixing temperature is 70°C, and the mixing time is 3.5 minutes; then transfer to the open mixer The ...

Embodiment 3

[0059] The flexible lead-free X-ray protective material in this embodiment consists of the following raw materials in parts by mass:

[0060]

[0061]

[0062] In this embodiment, the radiation protection filler is nano-scale bismuth oxide powder and nano-scale boron carbide powder, bismuth oxide accounts for about 45.4% of the total raw material mass, and boron carbide accounts for about 22.7% of the total raw material mass.

[0063] Its preparation method is:

[0064] S1 mastication: Weigh the natural rubber with the formula amount, masticate it in the internal mixer, the mastication temperature is 70°C, and the mastication time is 4min;

[0065] S2 one-step mixing: After the raw rubber is masticated, add active agent, anti-aging agent MB, and processing aids for mixing. The mixing temperature is 70°C, and the mixing time is 3 minutes;

[0066] S3 secondary mixing: After S2 is completed, add protective filler, hydroxy silicone oil, and plasticizer to the internal mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lead equivalent | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com