Resveratrol-based flame retardant as well as preparation method and application thereof

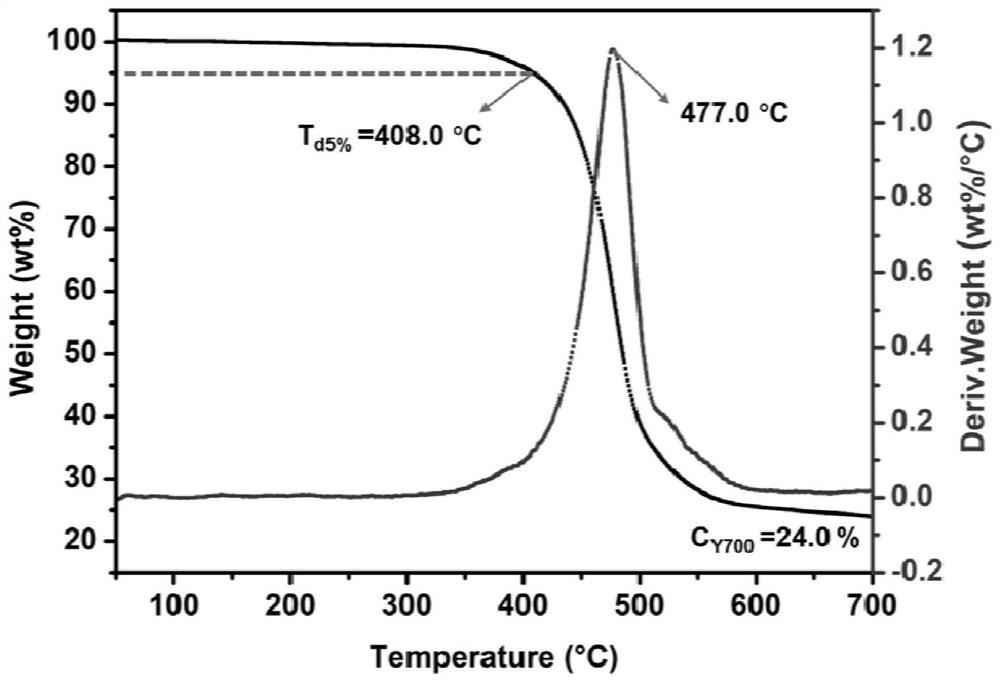

A technology of resveratrol and flame retardant, which is applied in the field of flame retardant, can solve the problems of complex preparation process, low flame retardant efficiency, poor thermal stability, etc., and achieve the advantages of simple preparation method, improved flame retardant performance and high thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] First, dissolve 3 g of resveratrol, 6.54 g of potassium carbonate, and 10 ml of triethylamine in 200 ml of tetrahydrofuran at 0°C, and then add 11.20 g of diphenylphosphinyl chloride dropwise under a nitrogen atmosphere. The reaction was moved into a 60°C oil bath to continue the reaction for 6 hours, and finally the resulting product was filtered and precipitated to remove the solvent, and then purified and dried, the off-white powder obtained was the resveratrol-based flame retardant of the present invention (yield: 90 %).

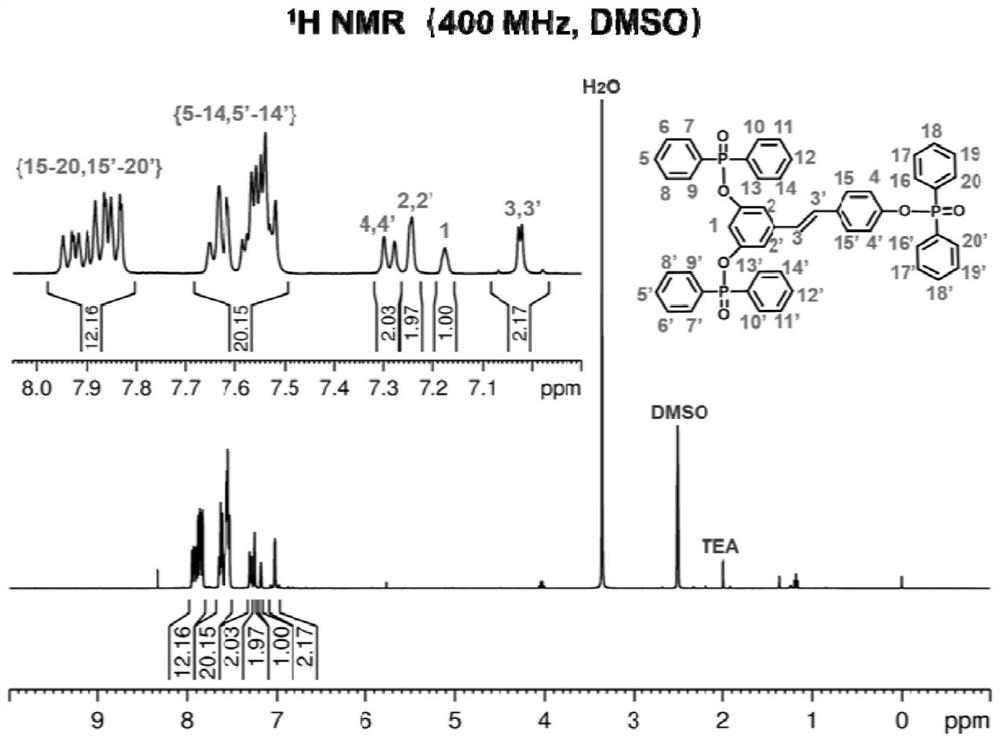

[0022] figure 1 Prepare the proton nuclear magnetic resonance spectrum figure of target product for embodiment 1 1 H NMR (400MHz, DMSO), the specific analysis is as follows (δ, ppm): the chemical shift of hydrogen on the double bond is 6.96-7.08, and the chemical shift of hydrogen on the benzene ring is 7.175, 7.22-7.26, 7.27-7.32, 7.50-7.67 , 7.80~7.96.

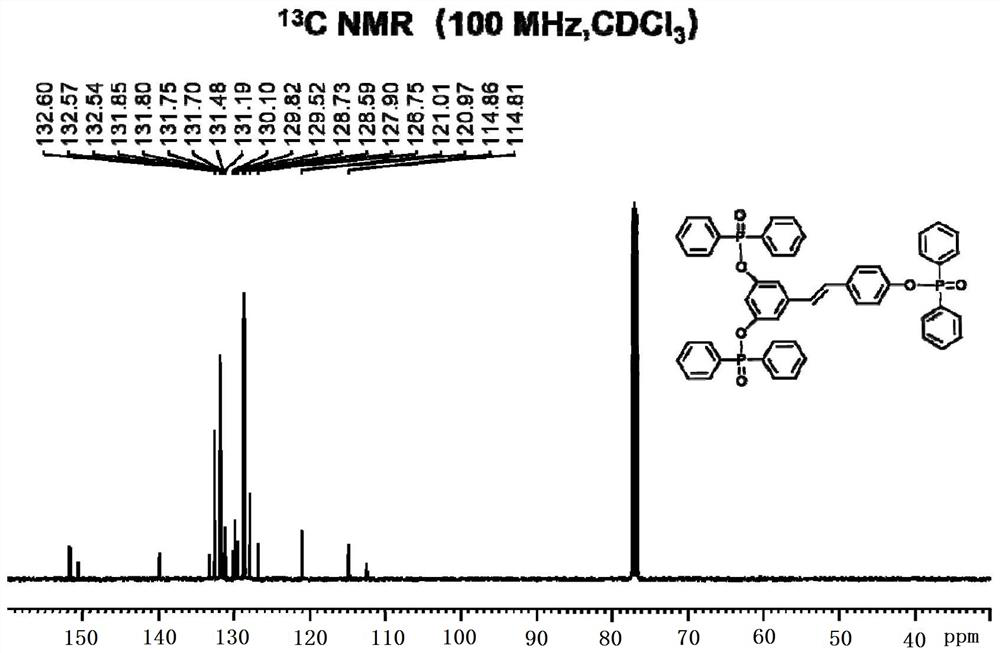

[0023] figure 2 Prepare the nuclear magnetic resonance phosphorus spectrogram of target...

Embodiment 2

[0027] Dissolve 3g of resveratrol, 6.34g of potassium carbonate, and 10ml of triethylamine in 200ml of dichloromethane at 1°C, and then add 11.197g of diphenylphosphinyl chloride dropwise under an air atmosphere. After the addition is complete, The reaction was moved into a 45°C oil bath to continue the reaction for 7 hours, and finally the product obtained was filtered and precipitated to remove the solvent, and then purified and dried, the off-white powder obtained was the resveratrol-based flame retardant of the present invention (yield: 81 %).

Embodiment 3

[0029] Dissolve 3g of resveratrol, 6.74g of potassium carbonate, and 10ml of triethylamine in 200ml of tetrahydrofuran at 2°C, and then add 11.166g of diphenylphosphinyl chloride dropwise under a nitrogen atmosphere. After the addition is complete, the reaction Move it into an oil bath at 55°C to continue the reaction for 8 hours, and finally filter and precipitate the resulting product to remove the solvent, then purify and dry, and the off-white powder obtained is the resveratrol-based flame retardant of the present invention (yield: 79%) .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com